Preparation method for CdS or CdSe single-crystal nanowire array

A single crystal nanowire array technology, applied in the field of preparation of CdS or CdSe single crystal nanowire arrays, can solve the problems of low crystallinity, complex steps, low yield, etc., and achieve high crystallinity, simple steps, and low defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Put the CdS single wafer into the ceramic sheet, and then place the ceramic sheet in the high-temperature heating zone of the tube furnace; the purity of the hexagonal CdS single wafer is 99.9%;

[0036] 2) Turn on the mechanical pump, vacuumize the tube furnace that puts the ceramic sheet, and reduce the pressure in the tube furnace to 0.1Pa, then feed argon and hydrogen into the tube furnace at a rate of 40mL / min. Mixed gas (the volume ratio of argon and hydrogen is 95:5), so that the pressure in the tube furnace is maintained at 200Pa; then the tube furnace is heated to 750 °C at a rate of 25 °C / min, and the pressure is 200 Pa. The reaction was carried out for 30 minutes; after the reaction, the tube furnace was naturally cooled to room temperature, and the samples were taken out. The sample is a CdS single crystal nanowire array.

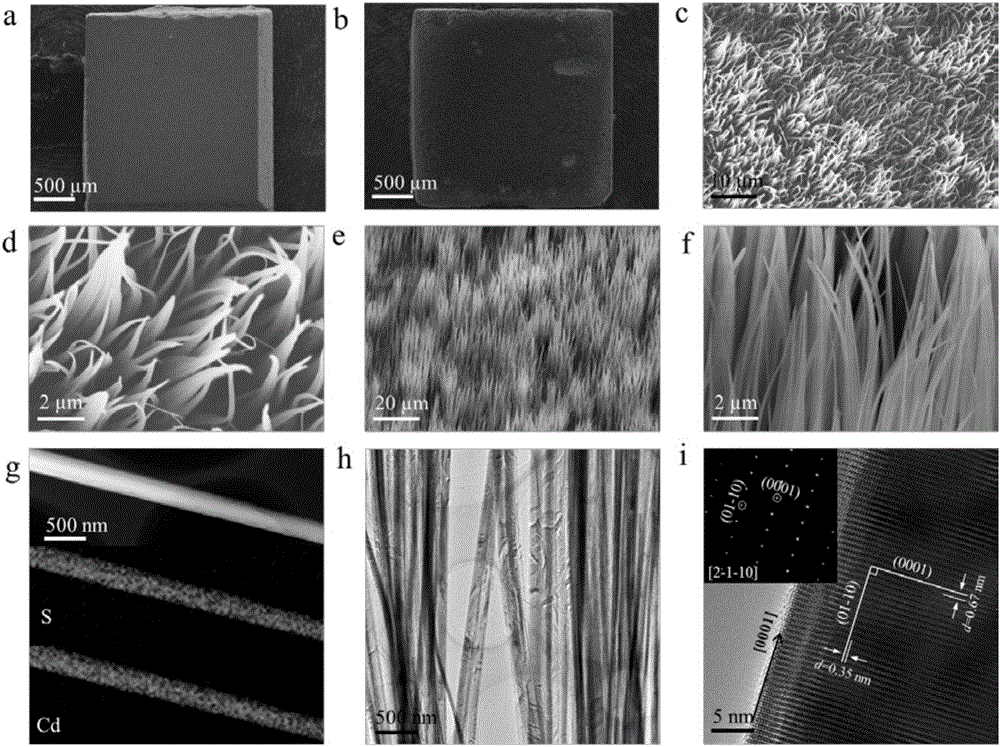

[0037] Depend on figure 1 Figure i in the figure shows that the HRTEM image and SAED image of the CdS single crystal nanowire array...

Embodiment 2

[0039] 1) putting CdS powder particles with a particle size greater than 5 μm into a ceramic sheet, and then placing the ceramic boat in a high-temperature heating zone of a tube furnace; the purity of the CdS powder particles is 99.9%;

[0040]2) Turn on the mechanical pump, vacuumize the tube furnace that puts the ceramic sheet, and reduce the pressure in the tube furnace to 0.1pa, then feed argon and hydrogen into the tube furnace at a rate of 40mL / min. Mixed gas (the volume ratio of argon and hydrogen is 95:5), so that the pressure in the tube furnace is maintained at 200Pa; then the tube furnace is heated to 750 °C at a rate of 25 °C / min, and the pressure is 200 Pa. The reaction was carried out for 30 minutes; after the reaction, the tube furnace was naturally cooled to room temperature, and the samples were taken out. The sample is a CdS single crystal nanowire array.

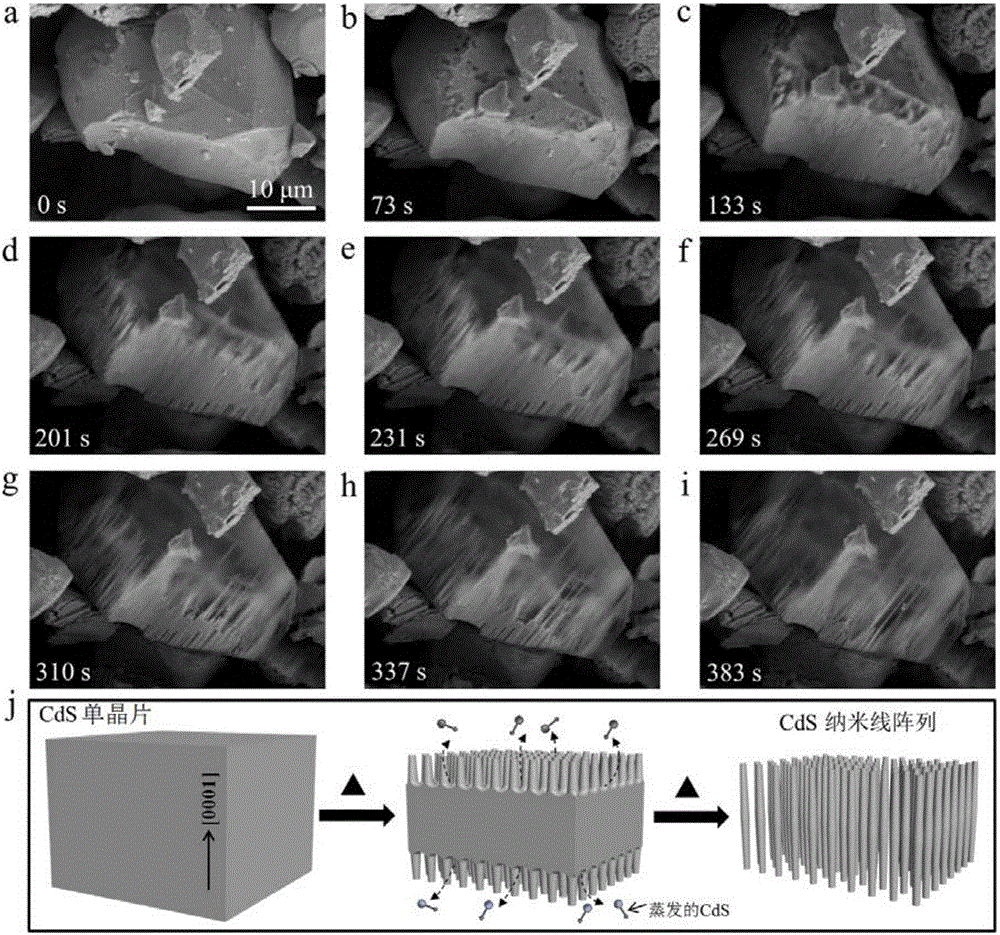

[0041] combine figure 2 Figures a to i in the figure show that the time-resolved ESEM images during...

Embodiment 3

[0043] 1) putting CdSe powder particles with a particle size greater than 5 μm into a ceramic sheet, and then placing the ceramic boat in a high-temperature heating zone of a tube furnace; the purity of the CdSe powder particles is 99.9%;

[0044] 2) Turn on the mechanical pump, vacuumize the tube furnace that puts the ceramic sheet, and reduce the pressure in the tube furnace to 0.1Pa, then feed argon and hydrogen into the tube furnace at a rate of 40mL / min. Mixed gas (the volume ratio of argon and hydrogen is 95:5), so that the pressure in the tube furnace is maintained at 200Pa; then the tube furnace is heated to 650 °C at a rate of 20 °C / min, and the pressure is 200 Pa. The reaction was carried out for 30 minutes; after the reaction, the tube furnace was naturally cooled to room temperature, and the samples were taken out. The sample is a CdSe single crystal nanowire array.

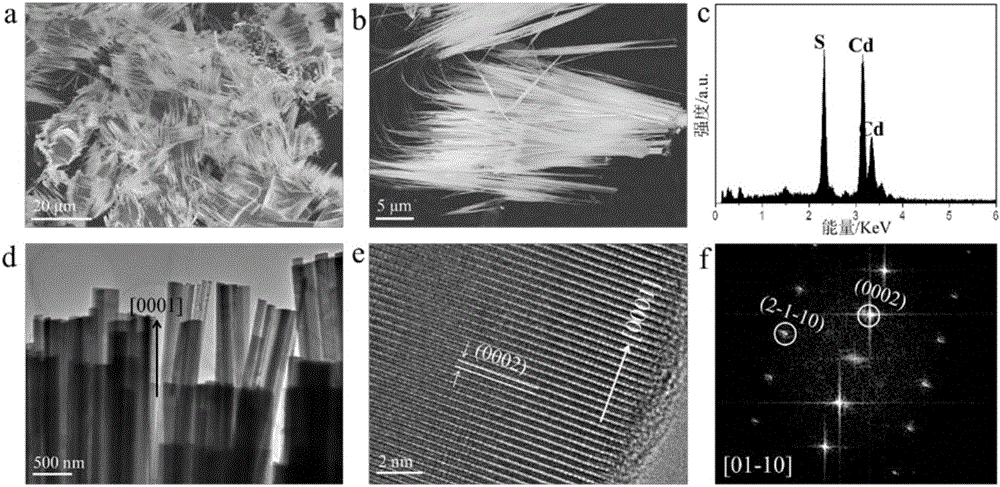

[0045] combined by Figure 4 Figure i shows that the HRTEM image and SAED image of the CdSe sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com