Electromechanical integrated pulsator controller

A technology of controller and servo controller, which is applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, shock absorber, etc., can solve the problems of liquid leakage, easy wear, etc., to reduce pulsation, reduce pressure and flow pulsation and impact, The effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

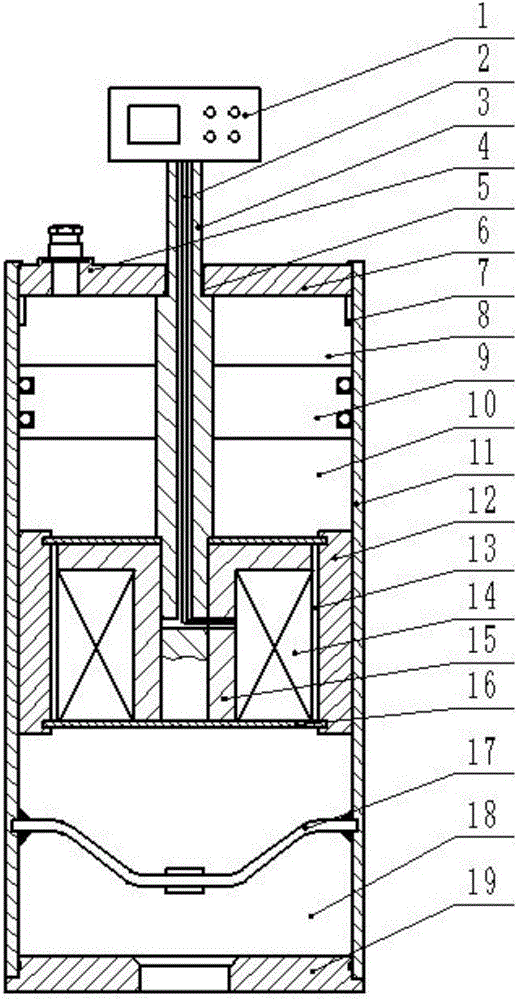

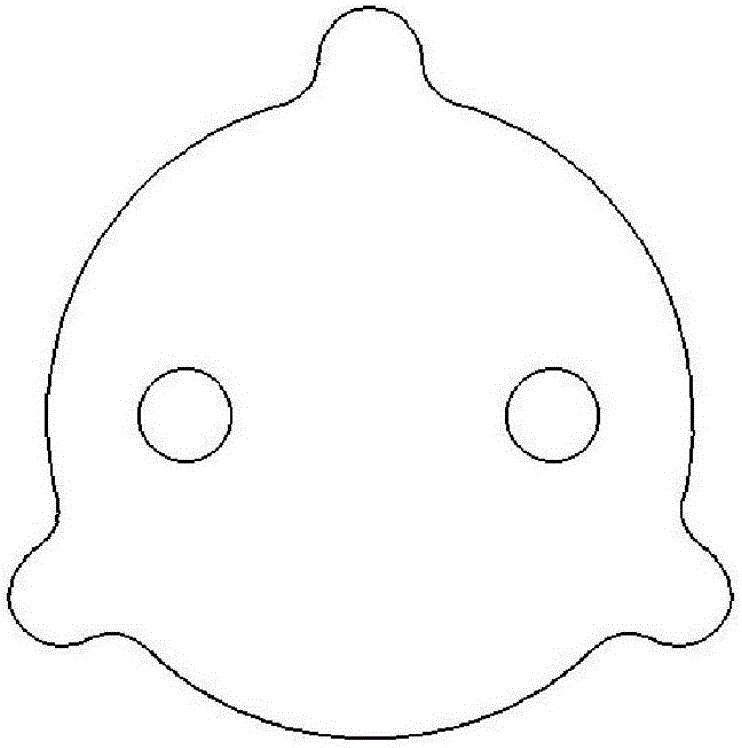

[0020] exist figure 1 and figure 2 In the schematic diagram of the present invention shown, the working cylinder 11 is a hollow cylinder with upper and lower openings, a lower end cover 19 is provided at the lower end of the working cylinder, and a through hole is provided in the middle of the lower end cover for connecting hydraulic pipelines. . In the working cylinder, the upper part of the lower end cover is fixedly connected with a liquid separation diaphragm 17, and there is a hydraulic oil chamber 18 between the liquid separation diaphragm and the lower end cover. The upper end of the working cylinder is fixedly connected with the upper end cover 6, and the upper end cover is provided with a threaded hole, and the bottom of the charging valve 4 is sleeved with the sealing ring 5, and is threaded with the upper end cover through the threaded hole. The limit sleeve 7 is fixedly connected to the bottom of the upper end cover. A through hole is provided in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com