Preparation method for SERS substrate of gold-silver composite nanometer particles

A nanoparticle, gold-silver composite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the impact of SERS activity and repeatability, cannot form nanostructures on a large scale, and affect the field of SERS Application and other issues, to achieve excellent SERS activity, simple and controllable preparation methods, and strong sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

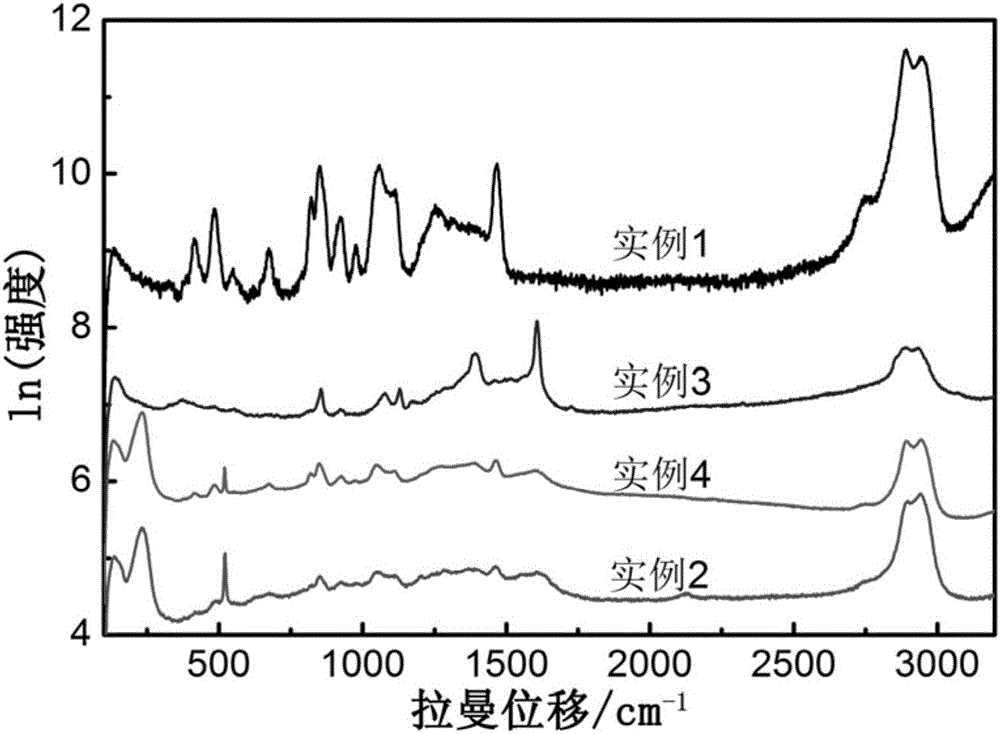

Embodiment 1

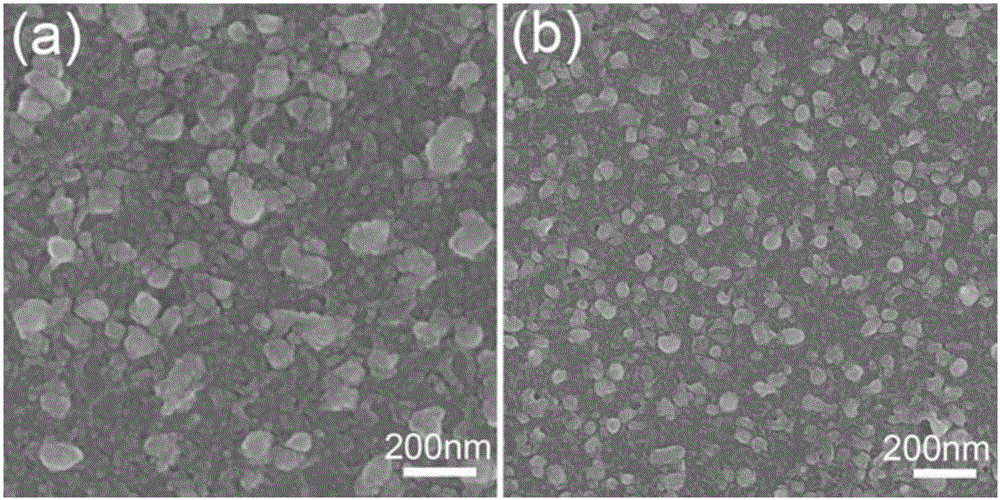

[0034] This embodiment provides a method for preparing a SERS substrate based on a co-sputtering method and a displacement method for preparing gold-silver composite nanoparticles, the method comprising the following steps:

[0035] a. Add 10ml of concentrated hydrochloric acid into a clean and dry round bottom flask, then put the cut silicon chip (1×1cm) into the concentrated hydrochloric acid, stir evenly at 100°C for 2 hours at a stirring speed of 80r / min; concentrated hydrochloric acid Concentrated hydrochloric acid is generally defined, that is, hydrochloric acid with a mass fraction exceeding 37%.

[0036] b. Take out the silicon wafer with clean tweezers, rinse it with alcohol and deionized water in turn, and dry it naturally for later use (cleaning the oil and other impurities on the surface of the silicon wafer will help the sputtered nanoparticle film to better adhere to on the base);

[0037] c. Put the clean silicon wafer into the sputtering chamber of the magnetr...

Embodiment 2

[0042] This embodiment provides a method for preparing a SERS substrate based on a co-sputtering method and a displacement method for preparing gold-silver composite nanoparticles, the method comprising the following steps:

[0043] a. Add 10ml of concentrated hydrochloric acid into a clean and dry round bottom flask, then put the cut silicon chip (1×1cm) into concentrated hydrochloric acid, stir evenly at 90°C for 1 hour, stirring speed 100r / min; concentrated hydrochloric acid Concentrated hydrochloric acid is generally defined, that is, hydrochloric acid with a mass fraction exceeding 37%.

[0044] b. Take out the silicon wafer with clean tweezers, rinse it with alcohol and deionized water in turn, and dry it naturally for later use;

[0045] c. Put the clean silicon wafer into the sputtering chamber of the magnetron sputtering system, start vacuuming and make the sputtering chamber pressure reach 10 -5 Pa;

[0046] d. the zinc target power is set to 20W, the silver target...

Embodiment 3

[0050] This embodiment provides a method for preparing a SERS substrate based on a co-sputtering method and a displacement method for preparing gold-silver composite nanoparticles, the method comprising the following steps:

[0051] a. Add 10ml of concentrated hydrochloric acid into a clean and dry round bottom flask, then put the cut silicon chip (1×1cm) into the concentrated hydrochloric acid, stir evenly at 80°C for 2 hours, and the stirring speed is 100r / min; concentrated hydrochloric acid Concentrated hydrochloric acid is generally defined, that is, hydrochloric acid with a mass fraction exceeding 37%.

[0052] b. Take out the silicon wafer with clean tweezers, rinse it with alcohol and deionized water in turn, and dry it naturally for later use;

[0053] c. Put the clean silicon wafer into the sputtering chamber of the magnetron sputtering system, start vacuuming and make the sputtering chamber pressure reach 10 -4 Pa;

[0054] d. the zinc target power is set to 30W, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com