Preparation method for high-flexibility samarium-cobalt permanent magnet

A permanent magnet, high toughness technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of weak mechanical properties of samarium cobalt permanent magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

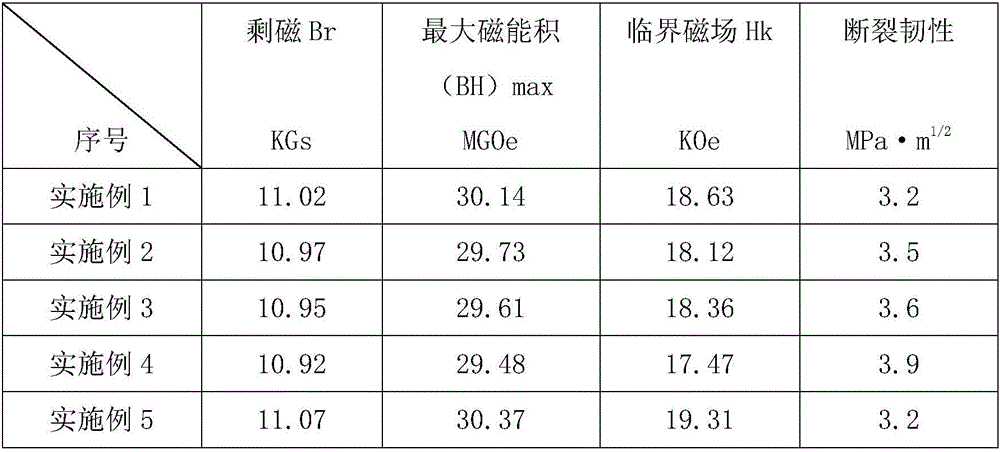

Examples

Embodiment 1

[0024] A method for preparing a high-toughness samarium-cobalt permanent magnet, comprising the following steps:

[0025] (1) The preparation raw material composition comprises: samarium is 26%wt, cobalt is 50%wt, copper is 5%wt, zirconium is 3%wt, iron is 16%wt;

[0026] (2) Place the prepared raw materials in a vacuum melting furnace, vacuumize the vacuum melting furnace to 4×10-2Pa, melt at a temperature of 1500° C. under the protection of argon to obtain a uniform alloy melt;

[0027] (3) cooling the molten alloy to 1300°C, and pouring it into the ingot mold cavity to obtain an ingot;

[0028] (4) the ingot is hydrogen broken to obtain the hydrogen broken product;

[0029] (5) Silver powder, a dispersant and an antioxidant with a particle size of 20 μm are added to the hydrogen incineration product in step (4), and then they are dropped into a jet mill, and high-purity nitrogen gas with a purity of 99.99% is used as a pulverizing gas to pulverize into a particle size of 3...

Embodiment 2

[0032] A method for preparing a high-toughness samarium-cobalt permanent magnet, comprising the following steps:

[0033] (1) The preparation raw material composition comprises: samarium is 27%wt, cobalt is 50%wt, copper is 5%wt, zirconium is 3%wt, iron is 15%wt;

[0034] (2) Place the prepared raw materials in a vacuum melting furnace, vacuumize the vacuum melting furnace to 5×10-2Pa, melt at a temperature of 1550° C. under the protection of argon to obtain a uniform alloy melt;

[0035] (3) cooling the molten alloy to 1350° C., pouring it into an ingot mold cavity to obtain an ingot;

[0036] (4) the ingot is hydrogen broken to obtain the hydrogen broken product;

[0037] (5) Adding silver powder, dispersant and antioxidant with a particle size of 30 μm to the hydrogen incineration product in step (4), then dropping into the jet mill, using high-purity nitrogen with a purity of 99.99% as the pulverizing gas, and pulverizing into a particle size of 4 μm The magnetic powder,...

Embodiment 3

[0040] A method for preparing a high-toughness samarium-cobalt permanent magnet, comprising the following steps:

[0041] (1) The preparation raw material composition comprises: samarium is 25%wt, cobalt is 49%wt, copper is 6%wt, zirconium is 3%wt, iron is 17%wt;

[0042] (2) Place the prepared raw materials in a vacuum melting furnace, vacuumize the vacuum melting furnace to 3 × 10-2Pa, and melt at a temperature of 1600°C under the protection of argon to obtain a uniform alloy melt;

[0043] (3) cooling the molten alloy to 1300° C., and pouring it into an ingot mold cavity to obtain an ingot;

[0044] (4) the ingot is hydrogen broken to obtain the hydrogen broken product;

[0045] (5) Silver powder, a dispersant and an antioxidant with a particle size of 40 μm are added to the hydrogen incineration product described in step (4), and then they are dropped into a jet mill, and high-purity nitrogen gas with a purity of 99.99% is used as a pulverizing gas to pulverize into a par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com