Oil-immersed power transformer

A voltage transformer and oil-immersed technology, applied in transformer/inductor casing, transformer/inductor cooling, transformer/inductor magnetic core, etc., can solve the problems of less materials, unsuitable transformers, high cost of liquid metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

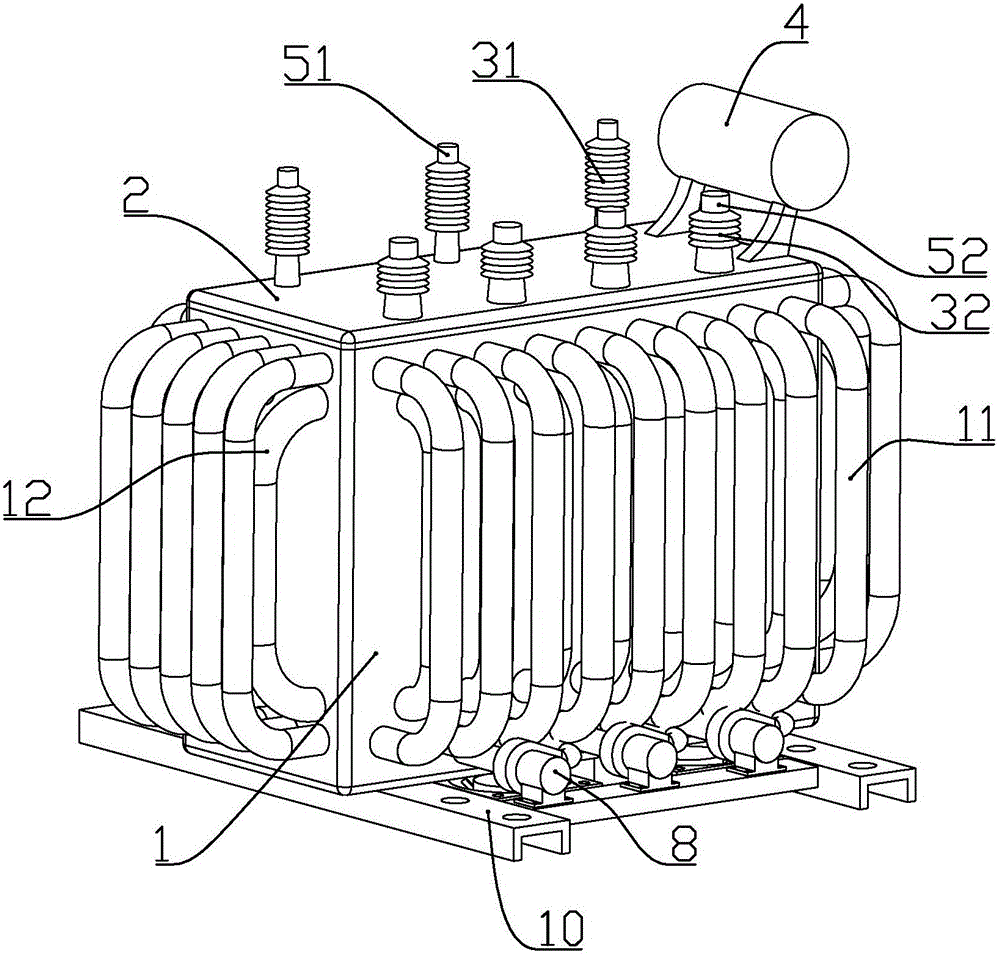

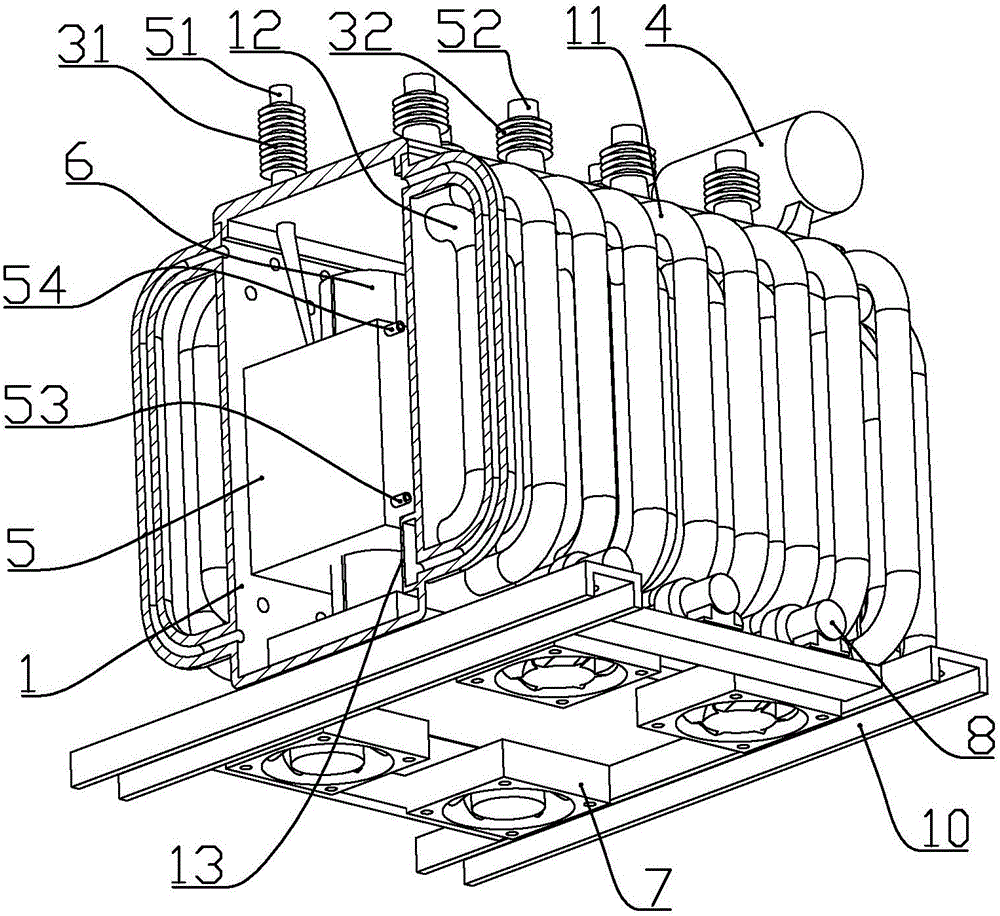

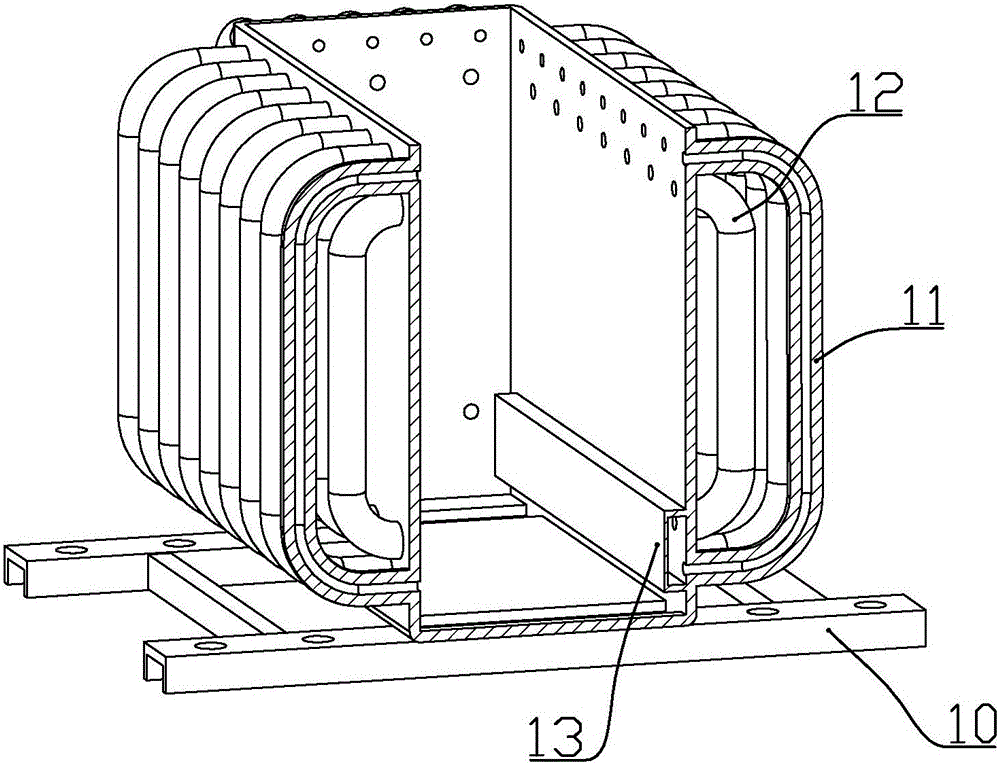

[0064] according to Figure 1 to Figure 8 As shown, this embodiment is an oil-immersed electric voltage transformer, which includes a box body 1 with an open upper end, a cover body 2 fixedly and sealingly connected to the upper end of the box body, an iron core 6 fixedly installed at the bottom of the box body, and a fixedly installed Winding assembly 5 on iron core.

[0065] The iron core includes three longitudinally arranged core columns and horizontal iron yokes connected to the upper and lower ends of each core column; the lower part of the iron core at the lower end of the iron core is connected with a base 61, and the base is connected to the box body. Bottom connection.

[0066] The winding assembly includes a ceramic base 50 and three sets of high-voltage winding coils 55 and three sets of low-voltage winding coils 56 integrally formed in the ceramic base. The coil is formed on the outer periphery of the port, and the high-voltage winding coil is located on the out...

Embodiment 2

[0086] In this embodiment, on the basis of Embodiment 1, the oil pump is further improved, specifically: combining Figure 9 to Figure 16 As shown, the oil pump 8 includes a centrifugal pump housing 82, an impeller 85 installed in the centrifugal pump housing, a piston pump housing 83 fixedly connected to one end of the centrifugal pump housing, and a piston member 88 slidingly installed in the piston pump housing. , and a motor 81 fixedly connected to the other end of the centrifugal pump casing for driving the impeller and the piston.

[0087] The motor is connected with a connecting frame 812, and the outer wall of the centrifugal pump casing is integrally formed with a connecting head 822, and the connecting head and the connecting frame are connected by screws; the side wall of the centrifugal pump casing is formed with a liquid outlet 821.

[0088] A drive turntable 811 is connected to the output shaft of the motor. The drive turntable is close to but not in contact wit...

Embodiment 3

[0104] according to figure 1 , figure 2 , Figure 9 to Figure 16 As shown, this embodiment is an oil-immersed electric voltage transformer, which includes a box body 1 with an open upper end, a cover body 2 fixedly and sealingly connected to the upper end of the box body, an iron core 6 fixedly installed at the bottom of the box body, and a fixedly installed Winding assembly 5 on iron core.

[0105] The iron core includes three longitudinally arranged core columns and horizontal iron yokes connected to the upper and lower ends of each core column; the lower part of the iron core at the lower end of the iron core is connected with a base 61, and the base is connected to the box body. Bottom connection.

[0106]The bottom of the box body is fixedly connected with a bracket 10 arranged horizontally, and the side of the box body is connected with a plurality of heat dissipation inner tubes 12 which are arranged vertically and are U-shaped as a whole. The outer side is also co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com