Agarose/polyaniline compound gel, method for preparing same and application of agarose/polyaniline compound gel

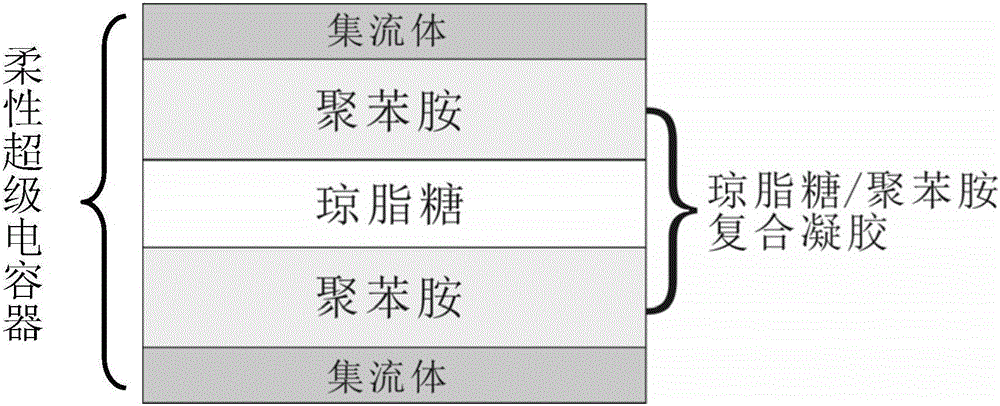

A technology of agarose gel and composite gel, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of poor mechanical strength and ionic conductivity, and achieve good flexibility and circulation Effects of stability, mild experimental conditions, good mechanical properties and flexible bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) At 80°C, dissolve 1 g of agarose powder in 5 mL of 1 mol / L Na 2 SO 4 solution, stirred for 0.5 h, poured into a mold while hot, and obtained agarose gel after cooling.

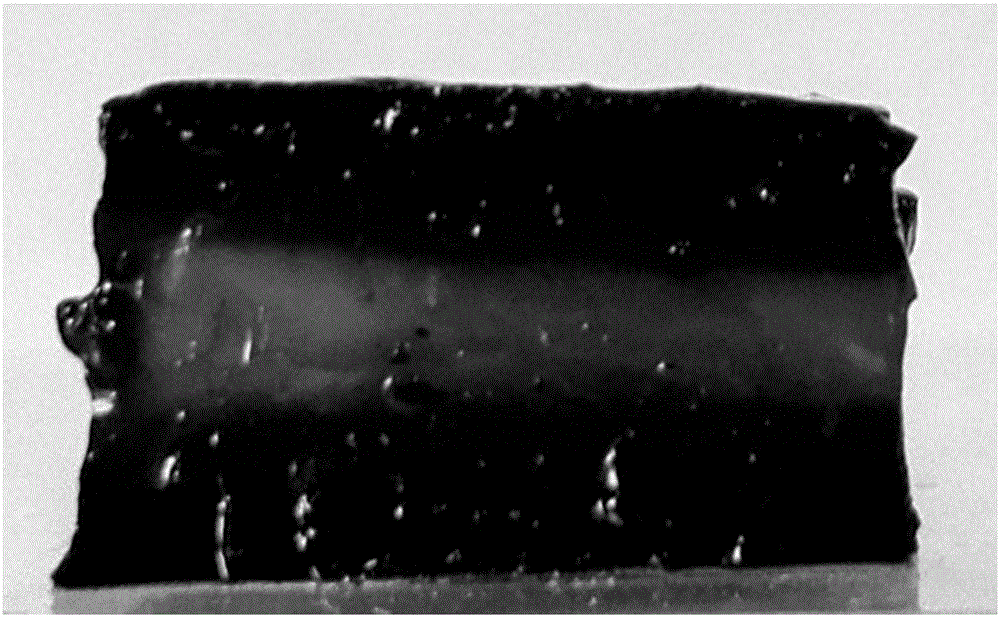

[0032] (2) Put 2 g of agarose gel in 15 mL of aniline solution with a concentration of 10 mg / mL for 2 hours, let the aniline adsorb on the surface of the agarose gel, and then immerse it in 30 mL of ammonium persulfate solution with a concentration of 0.5 mol / L for 2 hours. Agarose / polyaniline composite gel was obtained by oxidative polymerization. This composite gel has a sandwich polyaniline / agarose electrolyte / polyaniline integrated structure, and its cross-sectional photos are shown in figure 2 shown.

[0033] The graphene film is placed on the surface of the agarose / polyaniline composite gel to form a flexible supercapacitor based on the agarose / polyaniline composite gel.

[0034] In the case of bending the flexible supercapacitor, its performance was tested using an electrochemical workst...

Embodiment 2

[0036] (1) At 90°C, dissolve 0.5 g of agarose powder in 10 mL of 1 mol / L Na 2 SO 4 solution, stirred for 3 hours, poured into a mold while hot, and obtained agarose gel after cooling.

[0037] (2) Put 5 g of agarose gel in 5 mL of aniline solution with a concentration of 20 mg / mL for 2 h, let the aniline adsorb on the surface of the agarose gel, then immerse in 10 mL of ammonium persulfate solution with a concentration of 0.5 mol / L for 5 h, pass The agarose / polyaniline composite gel is obtained through oxidative polymerization, and the composite gel has a sandwich polyaniline / agarose electrolyte / polyaniline integrated structure.

[0038] The conductive carbon fibers are arranged on the surface of the agarose / polyaniline composite gel to form a flexible supercapacitor based on the agarose / polyaniline composite gel.

[0039] In the case of bending the flexible supercapacitor, its performance was tested using an electrochemical workstation (Shanghai Chenhua 660D). After consta...

Embodiment 3

[0041] (1) At 60°C, dissolve 0.3 g of agarose powder in 10 mL of 1 mol / L H 2 SO 4 solution, stirred for 10 hours, poured into a mold while hot, and obtained agarose gel after cooling.

[0042] (2) Put 5 g of agarose gel in 5 mL of aniline solution with a concentration of 20 mg / mL for 2 h, let the aniline adsorb on the surface of the agarose gel, then immerse it in 10 mL of ferric chloride solution with a concentration of 0.5 mol / L for 5 h, pass The agarose / polyaniline composite gel is obtained through oxidative polymerization, and the composite gel has a sandwich polyaniline / agarose electrolyte / polyaniline integrated structure.

[0043] The conductive carbon fibers are arranged on the surface of the agarose / polyaniline composite gel to form a flexible supercapacitor based on the agarose / polyaniline composite gel.

[0044] In the case of bending the flexible supercapacitor, its performance was tested using an electrochemical workstation (Shanghai Chenhua 660D). In the case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com