Photovoltaic cell and preparation method thereof

A photovoltaic cell and electrode technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as silicon-based batteries with high production cost efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

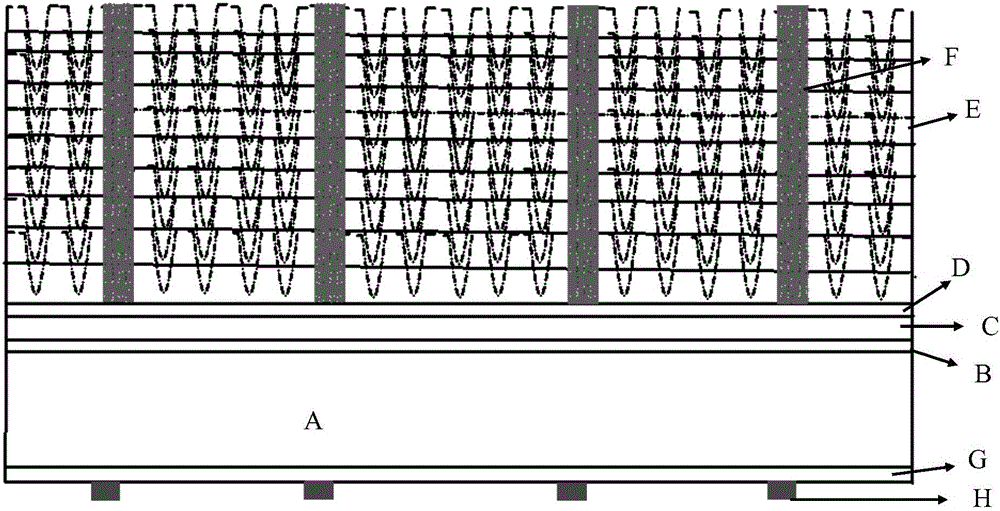

[0032] The present invention also provides a method for preparing the above-mentioned photovoltaic cell, comprising:

[0033] performing reactive ion etching on one side of the P-type substrate to obtain a reactive ion etching textured layer;

[0034] Diffusion is carried out in the reactive ion etching textured layer to form a PN junction layer;

[0035] Grooving is performed on the surface of the PN junction layer, and then coating is performed to form an anti-reflection film layer;

[0036] Printing electrode paste on the surface of the anti-reflection film layer to form grid line electrodes;

[0037] The back electrode paste is printed on the surface opposite to the contact surface of the P-type substrate and the reactive ion etching texture layer to form a back electric field and a back electrode.

[0038] Wherein, the P-type substrate, the reactive ion etching texture layer, the PN junction layer, the anti-reflection film layer, the grid line electrode, the back electr...

Embodiment 1

[0050] 1.1 Choose 156x156mm polysilicon wafers, the thickness of which is within the range of 210±10μm; clean the silicon wafers before making texture, remove the loss layer and impurities of the original sheet itself, and form a texture layer; the thinning amount is controlled between 0.25 ~ 0.35g .

[0051] 1.2 Put the multi-wafer prepared above into the RIE equipment for reactive ion dry etching to form a reactive ion etching texture layer with a circular hole diameter of 200-500 μm, in which Cl 2 The gas flow is controlled between 400 and 1200 sccm; O 2 The gas flow is controlled between 900 and 2000 sccm; SF 6 The gas input and output flow rates are 600-700sccm and 500-650sccm respectively, the reaction time is 3-5s, the reaction pressure is 24pa, and the power range is between 1000-2000W; the battery is black.

[0052] 1.3 Put the multi-wafer that has been dry-etched into the cleaning equipment for repair. The process is first HF pickling for 120s-deionized water washi...

Embodiment 2

[0060] 2.1 Select 156x156mm polysilicon wafers, the thickness of which is within the range of 210±10μm; the silicon wafers are pre-cleaned and textured to remove the loss layer and impurities of the original wafer itself to form a textured layer; the thinning amount is 0.25g.

[0061] 2.2 Put the multi-wafer prepared above into the RIE equipment for reactive ion dry etching to form a reactive ion etching texture layer with a circular hole diameter of 200-500 μm, in which Cl 2 The flow rate of gas is between 400sccm input and 1200sccm outflow; O 2 Gas flow control is 900sccm; SF 6 The input and output flow rates of the gas are between 600-700sccm and 500-650sccm respectively, the reaction time is 3sec, the reaction pressure is 24pa, and the power range is between 1000W; the battery is black; after this process, the reflectance is measured 9%.

[0062] 2.3 Put the above-mentioned dry-etched multi-chip into the cleaning equipment for repair, the process is first HF pickling for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com