Preparation method of shaddock peel based waste biomass macromolecule adsorbing material

A technology of waste biomass and adsorption materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high cost and poor effect, and achieve the effect of low cost, good adsorption effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

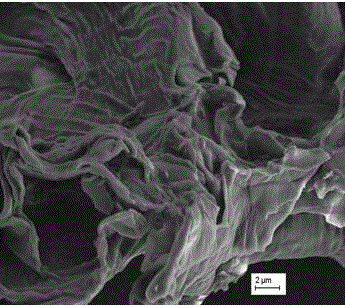

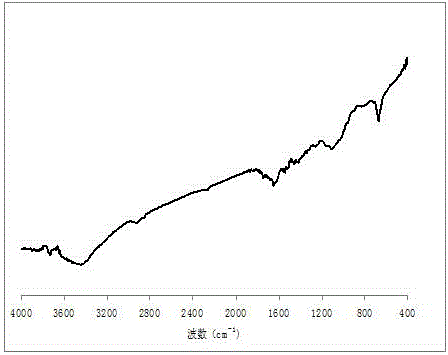

Image

Examples

Embodiment 1

[0027] Pretreatment of pomelo peel: cut the pomelo peel into small pieces, soak in water for 5-60 minutes, drain the water, dry at 40-60℃, and crush to 80-150 mesh to obtain pomelo peel powder.

[0028] Preparation of adsorption material: add 2.0 g of pomelo peel powder to 15 mL of distilled water, stir and disperse for 15 min to obtain a dispersion of pomelo peel powder; dissolve 1 g of methacrylic acid in 10 mL of sodium hydroxide aqueous solution (which contains sodium hydroxide 0.5 g), and added to the pomelo peel powder dispersion, then add 0.02 g of the cross-linking agent N,N'-methylene bisacrylamide, stir and disperse for 2 h, heat up to 60°C; add 0.04 g of potassium persulfate, Under the protection of nitrogen, the reaction was stirred for 1 h, the temperature was raised to 70°C, 0.1 g potassium persulfate was added again, the reaction was stirred for 2 h, filtered, the product was washed 3 to 5 times, and then dried at 60°C for 5 to 8 h, ground, A 100-mesh sieve was use...

Embodiment 2

[0031] Pretreatment of pomelo peel: same as Example 1;

[0032] Preparation of adsorption material: add 1.5 g of pomelo peel powder to 15 mL of distilled water, stir for 15 min to obtain a dispersion of pomelo peel powder; dissolve 1.0 g of methacrylic acid in 10 mL of sodium hydroxide aqueous solution (wherein, containing 0.4 g) and added to the pomelo peel powder dispersion, then add 0.02 g of crosslinking agent N,N'-methylene bisacrylamide, stir and disperse for 2 h; increase the temperature to 60°C, add 0.03 g of potassium persulfate, Under the protection of nitrogen, the reaction was stirred for 1 h; the temperature was raised to 70°C, then 0.05 g potassium persulfate was added, the reaction was stirred for 2 h, filtered, and the resulting product was washed with water 3-5 times, and then dried at 60°C for 5-8 h, and ground , Pass a 100-mesh sieve to obtain the pomelo peel-based waste biomass polymer adsorption material.

[0033] When the initial concentration of methylene bl...

Embodiment 3

[0035] Pretreatment of pomelo peel: same as Example 1;

[0036] Preparation of adsorption material: Add 3.0 g of pomelo peel powder to 15 mL of distilled water and stir for 15 min to obtain a dispersion of pomelo peel powder; dissolve 2 g of methacrylic acid in 15 mL of sodium hydroxide aqueous solution (wherein, containing 0.85 sodium hydroxide g) and added to the pomelo peel powder dispersion, then add 0.04 g of cross-linking agent epoxy resin, stir and disperse for 2 h; increase the temperature to 60°C, add 0.06 g of ammonium persulfate, and stir for 1 h under the protection of nitrogen After that, the temperature was raised to 75°C, 0.12 g of ammonium persulfate was added, the reaction was stirred for 2 h, filtered, and the resulting product was washed with water 3~5 times, then dried at 50°C for 5~8 h, ground, and passed through a 100 mesh sieve to obtain Pico-based biomass polymer adsorption material.

[0037] When the initial concentration of methylene blue solution is 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com