Emulsion wastewater treatment system and process

A waste water treatment system and technology for waste water treatment, which are used in cutting fluid waste water, machine tools, emulsions produced by hardware processing, emulsion waste water treatment systems, and emulsion waste water treatment technology fields. Easy to block and other problems, to achieve the effect of compact equipment process, low operating cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

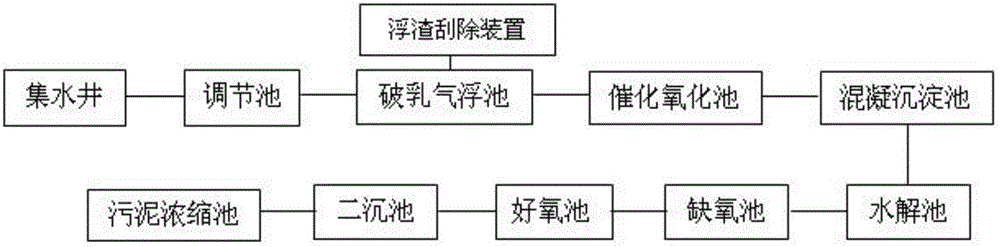

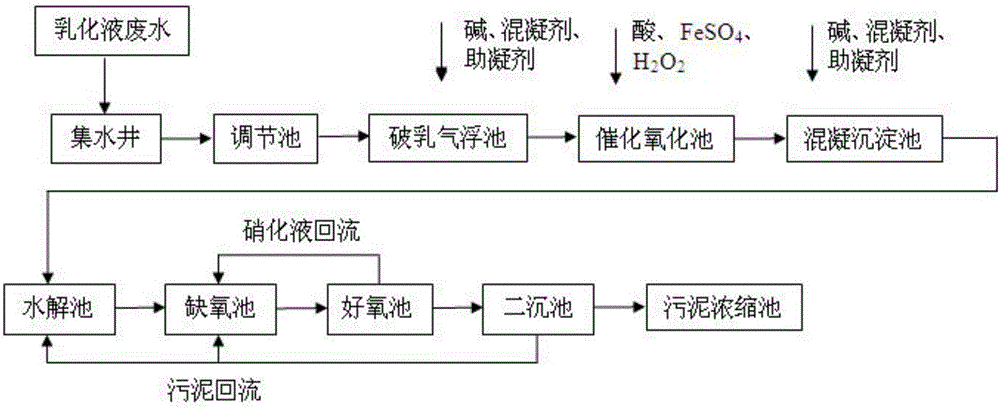

[0025] An emulsion wastewater treatment system, comprising a water collection well, the water collection well is connected with a regulating tank through a lifting pump, a liquid level gauge and a flow meter are arranged in the regulating pond, and the regulating pond is connected with a demulsification air flotation tank through a pipeline, and a demulsification air flotation tank is installed in the demulsification air flotation tank There are coagulation reaction area, contact area and separation area. The demulsification air flotation tank is connected to the catalytic oxidation tank through pipelines. The catalytic oxidation tank is equipped with pH controller and ORP controller. The catalytic oxidation tank is connected to the coagulation sedimentation tank through pipelines. The coagulation sedimentation tank is equipped with a pH adjustment area, a coagulation area, and a sedimentation area. The coagulation sedimentation tank is connected to the A / A / O biochemical pool th...

Embodiment 2

[0036] The emulsion wastewater treatment process comprises the following steps:

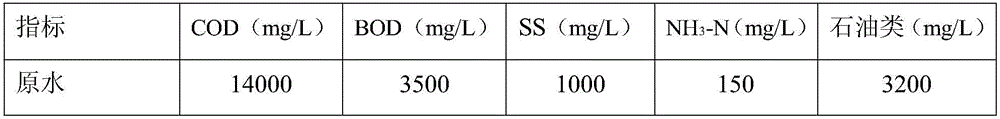

[0037] Step 1: Collect the emulsion wastewater into the water collection well, and the water from the water collection well enters the adjustment tank to effectively adjust the water quality and quantity of the emulsion wastewater, reduce the impact of the emulsion wastewater on the subsequent treatment facilities, reduce its impact load, and adjust The residence time in the pool is 8 hours. Part of the free floating oil in the waste water is concentrated into the sludge through the oil slick collection pipe, and the waste water after adjusting the water quality and water volume enters the demulsification air flotation tank, and a demulsifier is added in the demulsification air flotation tank. The demulsifier is Calcium sulfate, the dosage of calcium sulfate is 15mg / L. In addition, add coagulant PAC and coagulant aid PAM, the dosage of PAC is 18mg / L, and the dosage of PAM is 1.2mg / L. Pollutants ...

Embodiment 3

[0042] The emulsion wastewater treatment process comprises the following steps:

[0043] Step 1: Collect the emulsion wastewater into the water collection well, and the water from the water collection well enters the adjustment tank to effectively adjust the water quality and quantity of the emulsion wastewater, reduce the impact of the emulsion wastewater on the subsequent treatment facilities, reduce its impact load, and adjust The residence time in the pool is 7 hours. Part of the free floating oil in the waste water is concentrated into the sludge through the oil slick collection pipe, and the waste water after adjusting the water quality and water volume enters the demulsification air flotation tank, and a demulsifier is added in the demulsification air flotation tank. The demulsifier is Magnesium sulfate, the dosage of magnesium sulfate is 12mg / L. In addition, add coagulant PAC and coagulant aid PAM, the dosage of PAC is 20mg / L, and the dosage of PAM is 1.5mg / L. Polluta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com