A salt-bath rare earth chromium-titanium co-penetration agent and its application process

A technology of co-infiltration agent and chromium-titanium, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of low hardness of a single chromizing coating, excessive hardness difference of the substrate, and reducing the use of the coating Life and other issues, to achieve the effect of reducing operation complexity and processing time, reducing equipment costs and processing costs, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

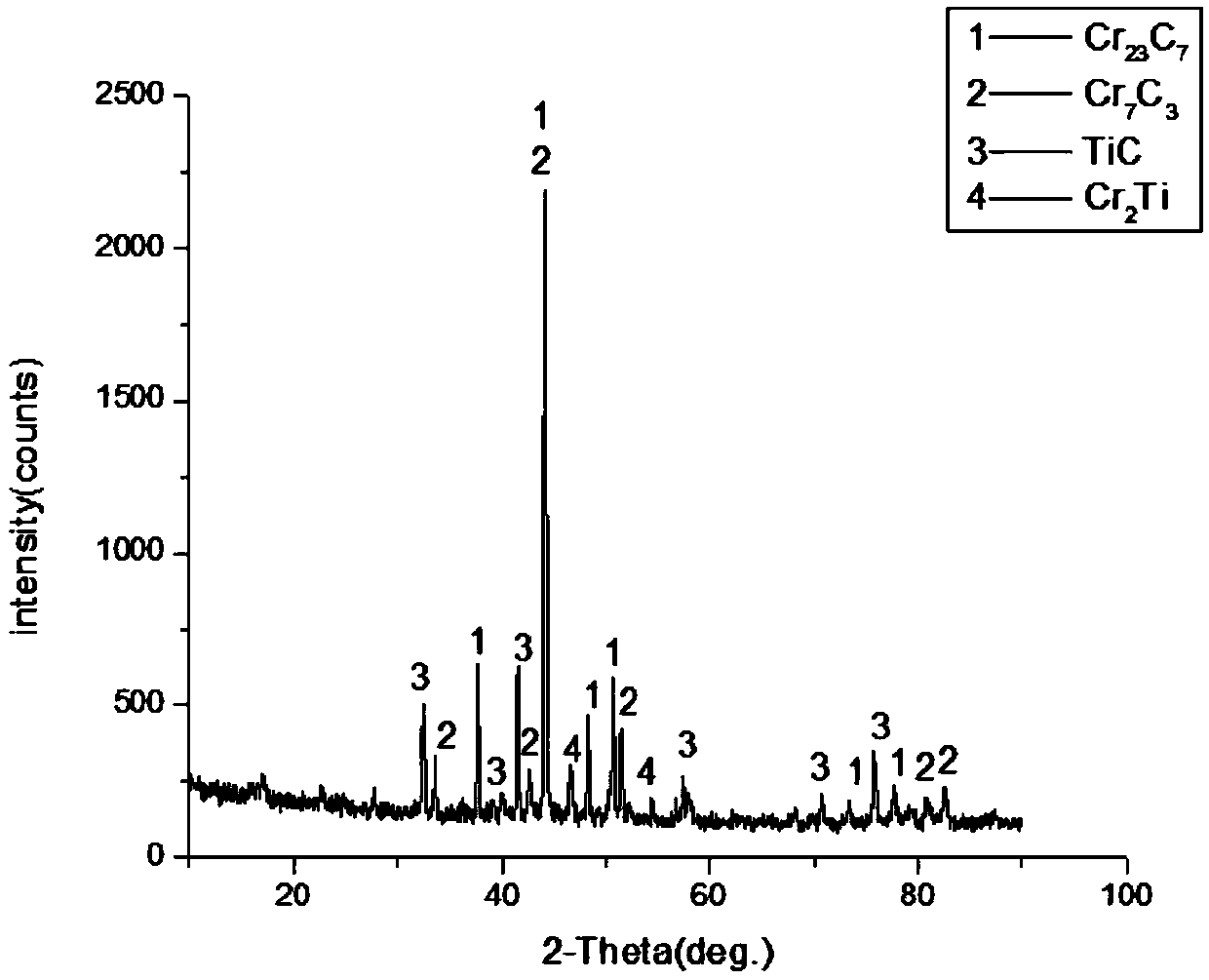

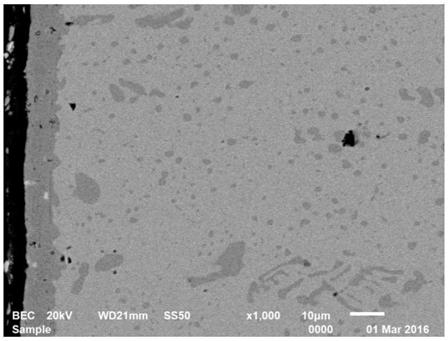

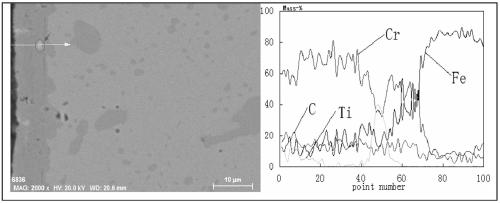

[0028] A salt-bath rare-earth chromium-titanium co-penetrating agent, which consists of 46% of barium dichloride, 23% of potassium chloride, 10% of titanium dioxide, 2% of chromium trioxide, 4% of aluminum powder, and cerium-rich Rare earth 7%, sodium fluoride 8%.

[0029] A kind of application technique of salt bath rare earth chromium-titanium infiltration agent, it comprises the steps:

[0030] (1) By weight percentage, weigh barium dichloride 46%, potassium chloride 23%, titanium dioxide 10%, chromium oxide 2%, aluminum powder 4%, cerium-rich rare earth 7%, sodium fluoride 8% ,spare;

[0031] (2) According to the above ratio, add barium dichloride and potassium chloride into the crucible, wait until the barium dichloride and potassium chloride melt and heat up to 850°C, then add the mixed titanium dioxide, chromium trioxide and fluoride sodium. When the temperature rises to 900°C, add a small amount of aluminum powder mixed with barium dichloride and potassium chloride ...

Embodiment 2

[0038] A salt-bath rare-earth chromium-titanium co-penetrating agent, which consists of 44% barium dichloride, 22% potassium chloride, 12% titanium dioxide, 3% chromium trioxide, 5% aluminum powder, and cerium-rich Rare earth 8%, sodium fluoride 6%.

[0039] A kind of application technique of salt bath rare earth chromium-titanium infiltration agent, it comprises the steps:

[0040] (1) By weight percentage, weigh barium dichloride 44%, potassium chloride 22%, titanium dioxide 12%, chromium oxide 3%, aluminum powder 5%, cerium-rich rare earth 8%, sodium fluoride 6% ,spare;

[0041] (2) According to the above ratio, add barium dichloride and potassium chloride into the crucible, wait until the barium dichloride and potassium chloride melt and heat up to 850°C, then add the mixed titanium dioxide, chromium trioxide and fluoride sodium. When the temperature rises to 900°C, add a small amount of aluminum powder mixed with barium dichloride and potassium chloride and cerium-rich...

Embodiment 3

[0048]A salt-bath rare-earth chromium-titanium co-penetrating agent, which consists of 48% barium dichloride, 24% potassium chloride, 8% titanium dioxide, 1% chromium trioxide, 3% aluminum powder, and cerium-rich Rare earth 6%, sodium fluoride 10%.

[0049] A kind of application technique of salt bath rare earth chromium-titanium infiltration agent, it comprises the steps:

[0050] (1) By weight percentage, weigh barium dichloride 48%, potassium chloride 24%, titanium dioxide 8%, chromium oxide 1%, aluminum powder 3%, cerium-rich rare earth 6%, sodium fluoride 10% ,spare;

[0051] (2) According to the above ratio, add barium dichloride and potassium chloride into the crucible, wait until the barium dichloride and potassium chloride melt and heat up to 850°C, then add the mixed titanium dioxide, chromium trioxide and fluoride sodium. When the temperature rises to 900°C, add a small amount of aluminum powder mixed with barium dichloride and potassium chloride and cerium-rich ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com