Online detection method based on robot unit ore sample preparation system

A sample preparation system and detection method technology, applied in the field of mining equipment, can solve problems such as interruption of material flow, sticking and clogging of conveying pipelines, particle size detection, etc., and achieve the effects of flexible mobility, high automation level, and reduced water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

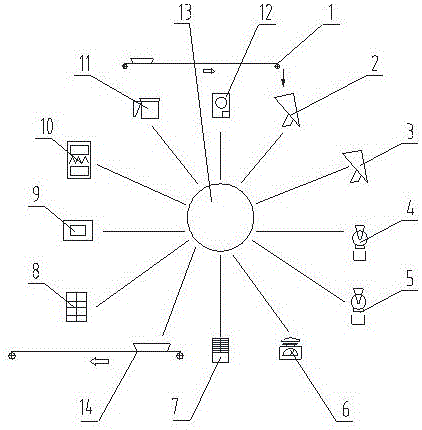

[0021] Such as figure 1 As shown, a robotic unit ore sample preparation system includes a feeding belt conveyor 1, a primary shrinking machine 2, a secondary shrinking machine 3, a primary crusher 4, a secondary crusher 5, an electronic balance 6, a vibrating screen 7, and a sieve Grid frame 8, cleaner 9, oven 10, sample collector 11, grinder 12, robot 13, belt conveyor 14 for waste. A device for sample preparation operations, including the ability to use robots 13 to perform grabbing, placement, and dumping operations between any process equipment, and to analyze the particle size composition of the mined ore through the ore sample preparation method, moisture and chemical samples preparation and moisture content determination.

[0022] The online particle size analysis of mined ore, including lump ore, pellet ore, and fine ore with smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com