a cu 3 bis 3 Film Preparation Method

A technology of thin film and precursor solution, which is applied in the field of preparation of Cu3BiS3 thin film, can solve the problems of not obvious progress, difficulty in battery preparation, high equipment cost, etc., achieve low cost, reduce annealing temperature and annealing time, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cu in this example 3 BY 3 The preparation method of film comprises the following steps:

[0027] Step 1. Preparation of precursor solution: add 3.2mmol of copper acetate, 1mmol of bismuth acetate and 1mmol of thiuram into 2mL of N,N-dimethylformamide, ultrasonically dissolve and mix well to prepare a precursor solution;

[0028] Step 2. Film production: spin-coat the precursor solution on the FTO glass by spin-coating method, the spin-coating parameters are 1500rpm spin-coating for 20s, then dry at 300°C for 2min, repeat the spin-coating and drying process several times to obtain the precursor film;

[0029] Step 3, annealing: anneal the precursor film at 300 ° C for 30 min in an atmosphere of S element to obtain Cu 3 BY 3 film.

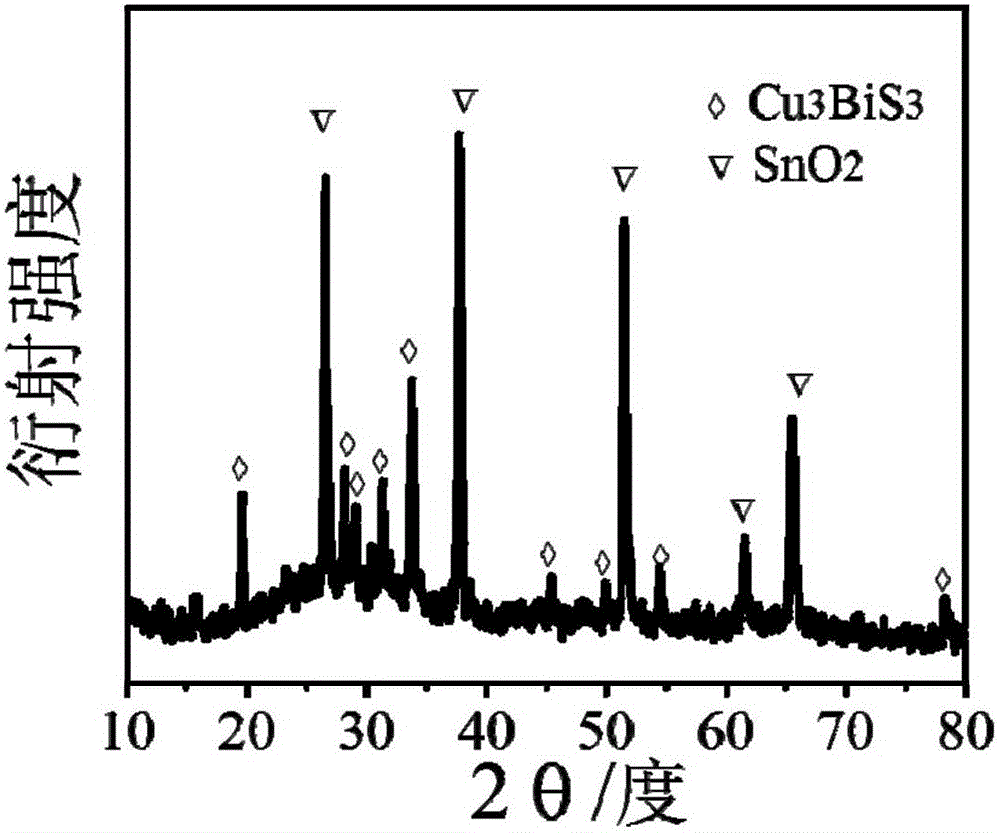

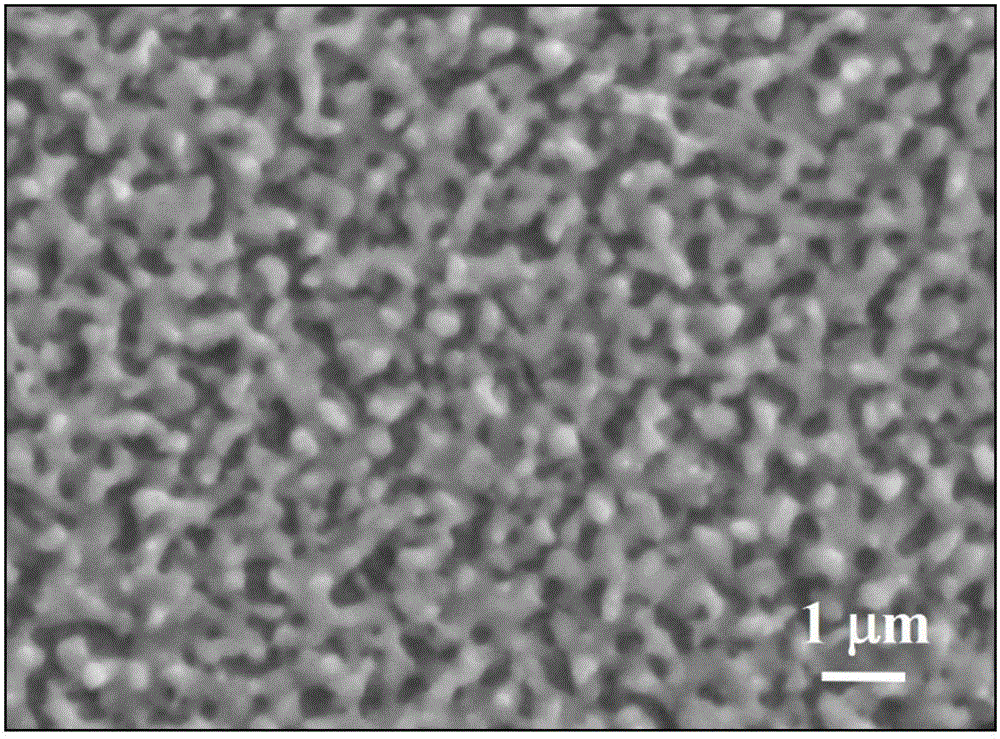

[0030] figure 1 For the Cu prepared in this embodiment 3 BY 3 The XRD pattern of the film, from figure 1 It can be seen that, except for the diffraction peak of FTO glass, the rest of the diffraction peaks correspond to Cu 3 BY 3 Pha...

Embodiment 2

[0032] Cu in this example 3 BY 3 The preparation method of film comprises the following steps:

[0033] Step 1. Preparing a precursor solution: Add 0.7 mmol of copper nitrate, 0.2 mmol of bismuth nitrate and 0.2 mmol of thiuram to 2 mL of N,N-dimethylformamide, and ultrasonically dissolve and mix uniformly to prepare a precursor solution.

[0034] Step 2. Film formation: spin-coat the precursor solution on the FTO glass by spin-coating method, the spin-coating parameter is 2000rpm spin-coating for 20s, then dry at 300°C for 2min, repeat this process several times to obtain the precursor film;

[0035] Step 3, annealing: anneal the precursor film at 400°C for 10h in an atmosphere of S element to obtain Cu 3 BY 3 film.

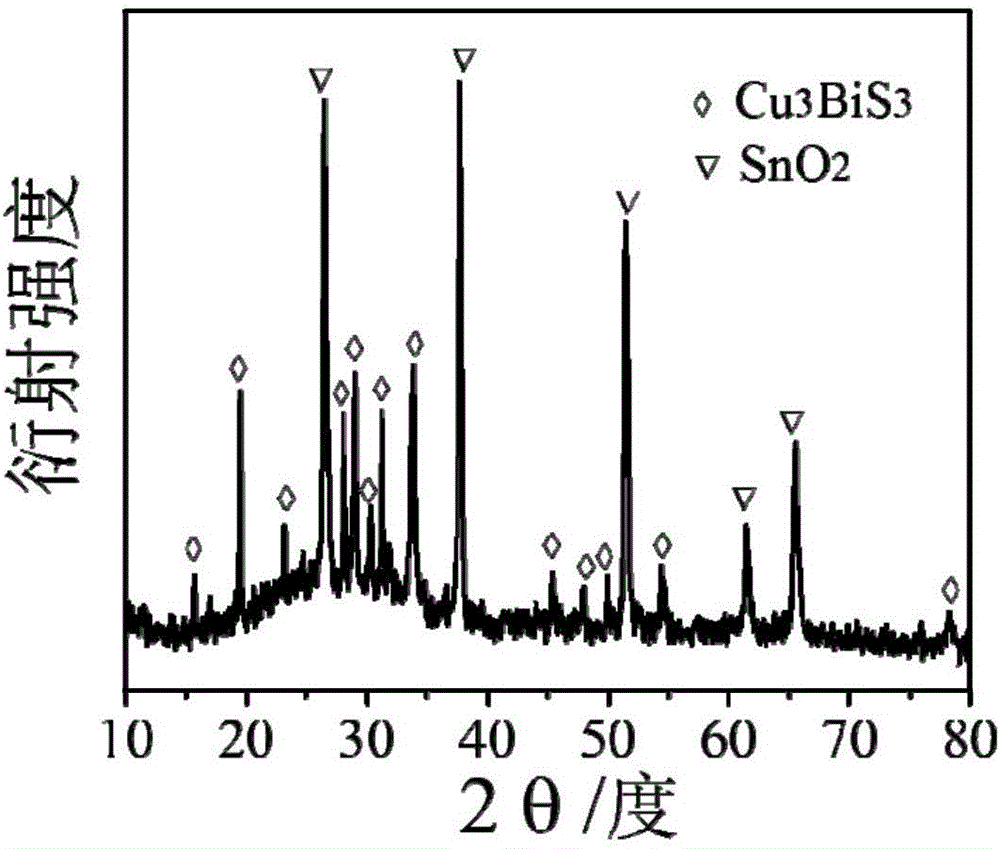

[0036] image 3 For the Cu prepared in this embodiment 3 BY 3 The XRD pattern of the film, from image 3 It can be seen that the film prepared in this example is Cu 3BY 3 pure phase.

Embodiment 3

[0038] Cu in this example 3 BY 3 The preparation method of film comprises the following steps:

[0039] Step 1. Preparation of precursor solution: add 1.4 mmol of copper chloride, 0.5 mmol of bismuth chloride and 0.5 mmol of thiuram to 2 mL of dimethyl sulfoxide, dissolve and mix uniformly by ultrasonic to prepare a precursor solution;

[0040] Step 2. Film formation: spin-coat the precursor solution on the molybdenum film on the surface of the glass substrate by spin-coating. The spin-coating parameter is 1500rpm for 20s, and then dry at 200°C for 5min. Repeat this process several times to obtain the precursor film ;

[0041] Step 3, annealing: anneal the precursor film at 300°C for 3 hours in a hydrogen sulfide atmosphere to obtain Cu 3 BY 3 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com