An Excitation Modulated Anode Assisted Magnetron Sputtering Ion Coating System

A technology of ion coating and magnetron sputtering, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems that target poisoning is difficult to control and affects the controllability and repeatability of coating, and achieves Increased collision probability, increased ionization rate and sputtering yield, and the effect of increasing sputtering yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

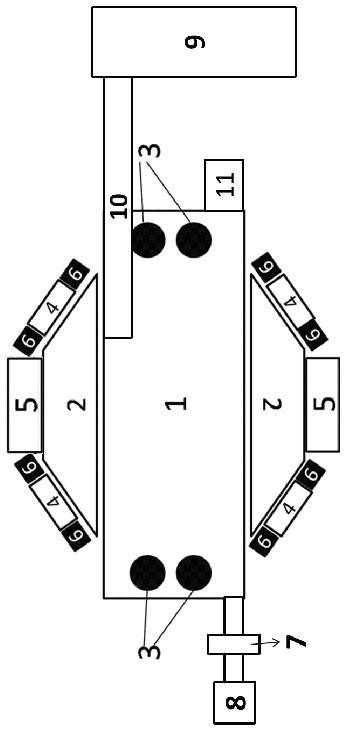

[0028] Such as figure 1 As shown, an excitation modulation anode assisted magnetron sputtering ion coating system includes a vacuum chamber 1 connected together, a vacuum pump group 8, a vacuum measuring device 11 composed of a group of composite vacuum gauges, a power control cabinet and an automatic programming Controlled PLC+ICP+closed-loop control system9. One side of the vacuum chamber 1 is connected to the vacuum pump group 8 through the pipeline valve body 7 through the air pumping hole, and the other side is connected to the vacuum measuring device 11; A pair of planar magnetron targets 5 are arranged symmetrically on the front of the vacuum chamber door 2, and two pairs of auxiliary water-cooled anodes 4 with their own gas distribution systems are arranged symmetrically on the side; excitation field modulation coils 6 are arranged on the periphery of each auxiliary water-cooled anode 4; Two pairs of twin column magnetron sputtering cathodes 3 are symmetrically insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com