A kind of algainp-based light-emitting diode wafer with high brightness reverse polarity and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing product yield, identification difficulty, and product competitiveness, etc., and achieve luminous efficiency and product yield. the effect of improving the competitiveness of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Manufacturing process steps:

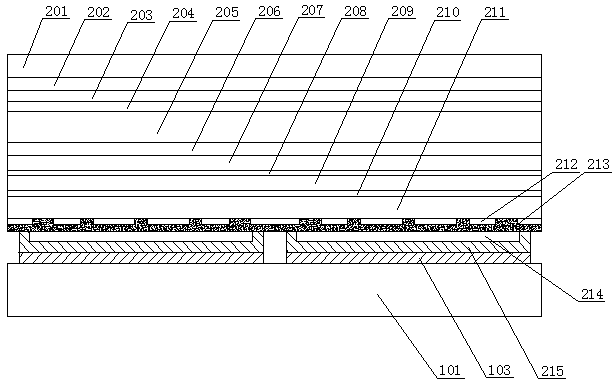

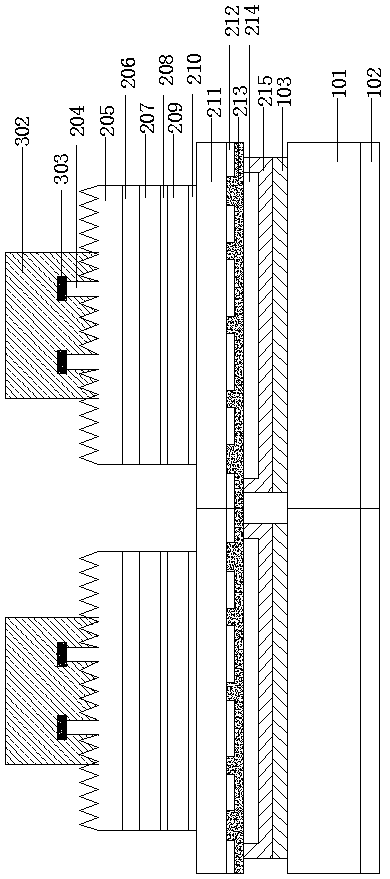

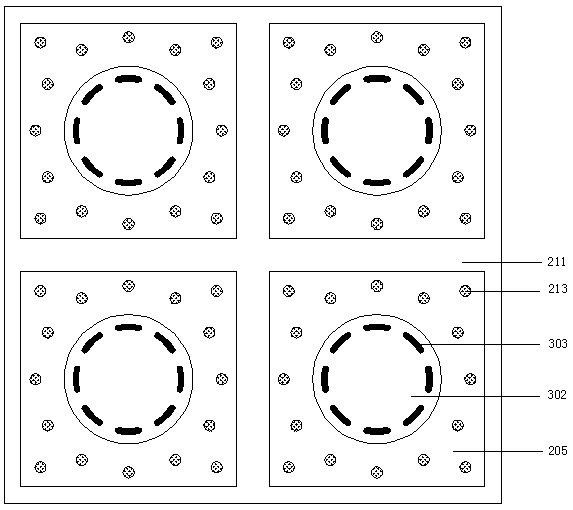

[0030] 1. If figure 1 As shown, an epitaxial layer is grown on a GaAs temporary substrate 201 by MOCVD equipment, and the epitaxial layer includes a transition layer 202, an N-GaInP cut-off layer 203, an N-GaAs ohmic contact layer 204, an N-AlGaInP roughening layer 205, and an N-AlGaInP Current spreading layer 206 , N-AlGaInP confinement layer 207 , MQW multi-quantum well active layer 208 , P-AlGaInP confinement layer 209 , buffer layer 210 , and P-GaP window layer 211 .

[0031] Wherein the thickness of the N-GaAs ohmic contact layer 204 is 35-50nm (preferably 40nm), the doping element is Si, and the doping concentration is 1×10 19 cm -3 Above, to ensure that the N surface has a good current spreading ability; the thickness of the N-AlGaInP current spreading layer 206 is 2000nm; the thickness of the P-GaP window layer 211 is 1500-3000nm (preferably 2000nm), the doping element is Mg, doped Concentration at 1×10 18 cm -3 Above, to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com