Method for preparing hollow microporous carbon sphere coated nanometer sulfur molecular material

A molecular material, microporous carbon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limited energy density, inability to meet technological development, etc., to achieve simple equipment requirements, The method is simple and feasible, and the effect is conducive to the transmission of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

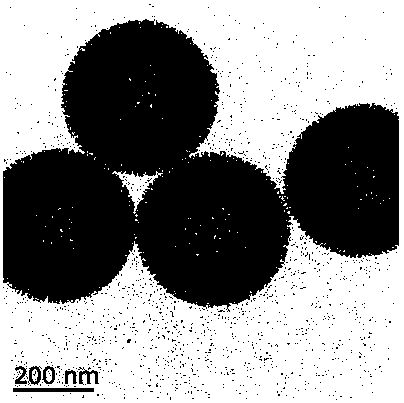

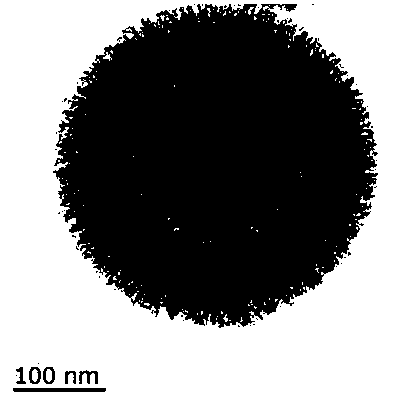

[0026] 1) Preparation of hollow microporous carbon spheres: Dissolve 12mmol (3.46mL) tetrapropoxysilane (TPOS) in a solution consisting of 70mL ethanol, 10mL water and 3mL ammonia water, and stir for 15min. Then 0.4 g of resorcinol and 1 mL of formaldehyde were added, and the reaction was carried out for 24 hours with stirring.

[0027] After the reaction, centrifuge at 5000r / min for 10min, take the solid phase for washing and collect the solid.

[0028] Calcinate the collected solid at 700°C under argon, then mix it with 10% HF aqueous solution for corrosion reaction, remove the silicon dioxide in it, and finally centrifuge at 5000r / min for 10min, take the solid phase and wash it twice with water, then wash it with ethanol for 1 After drying at 60°C, the solid was collected to obtain hollow microporous carbon spheres.

[0029] 2) Preparation of hollow microporous carbon sphere-coated nano-sulfur molecular material: the prepared hollow microporous carbon sphere and sublimed s...

Embodiment 2

[0031] 1) Preparation of hollow microporous carbon spheres: Dissolve 60mmol (17.3ml) tetrapropoxysilane (TPOS) in a solution containing 350mL ethanol, 50mL water and 15mL ammonia water, and stir for 15min. Then 2.0 g of resorcinol and 5 mL of formaldehyde were added, and the reaction was carried out under stirring for 24 hours.

[0032] After the reaction, centrifuge at 5000r / min for 10min, take the solid phase for washing and collect the solid.

[0033] Calcinate the collected solid at 700°C under argon, then mix it with 10% HF aqueous solution for corrosion reaction, remove the silicon dioxide in it, and finally centrifuge at 5000r / min for 10min, take the solid phase and wash it twice with water, then wash it with ethanol for 1 After drying at 60°C, the solid was collected to obtain hollow microporous carbon spheres.

[0034] 2) Preparation of hollow microporous carbon sphere-coated nano-sulfur molecular material: the prepared hollow microporous carbon sphere and sublimed s...

Embodiment 3

[0036] 1) Preparation of hollow microporous carbon spheres: Dissolve 120mmol (34.6ml) tetrapropoxysilane (TPOS) in a solution containing 700mL ethanol, 500mL water and 30mL ammonia water, and stir for 15min. Then add 4.0% resorcinol and 10mL formaldehyde, and react under stirring condition for 24 hours.

[0037] After the reaction, centrifuge at 5000r / min for 10min, take the solid phase for washing and collect the solid.

[0038] Calcinate the collected solid at 700°C under argon, then mix it with 10% HF aqueous solution for corrosion reaction, remove the silicon dioxide in it, and finally centrifuge at 5000r / min for 10min, take the solid phase and wash it twice with water, then wash it with ethanol for 1 After drying at 60°C, the solid was collected to obtain hollow microporous carbon spheres.

[0039] 2) Preparation of hollow microporous carbon sphere-coated nano-sulfur molecular material: the prepared hollow microporous carbon sphere and sublimed sulfur were ground and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com