Ti<4+> and Cr<3+>-doped iron trifluoride composite material and preparation method therefor, and lithium ion battery

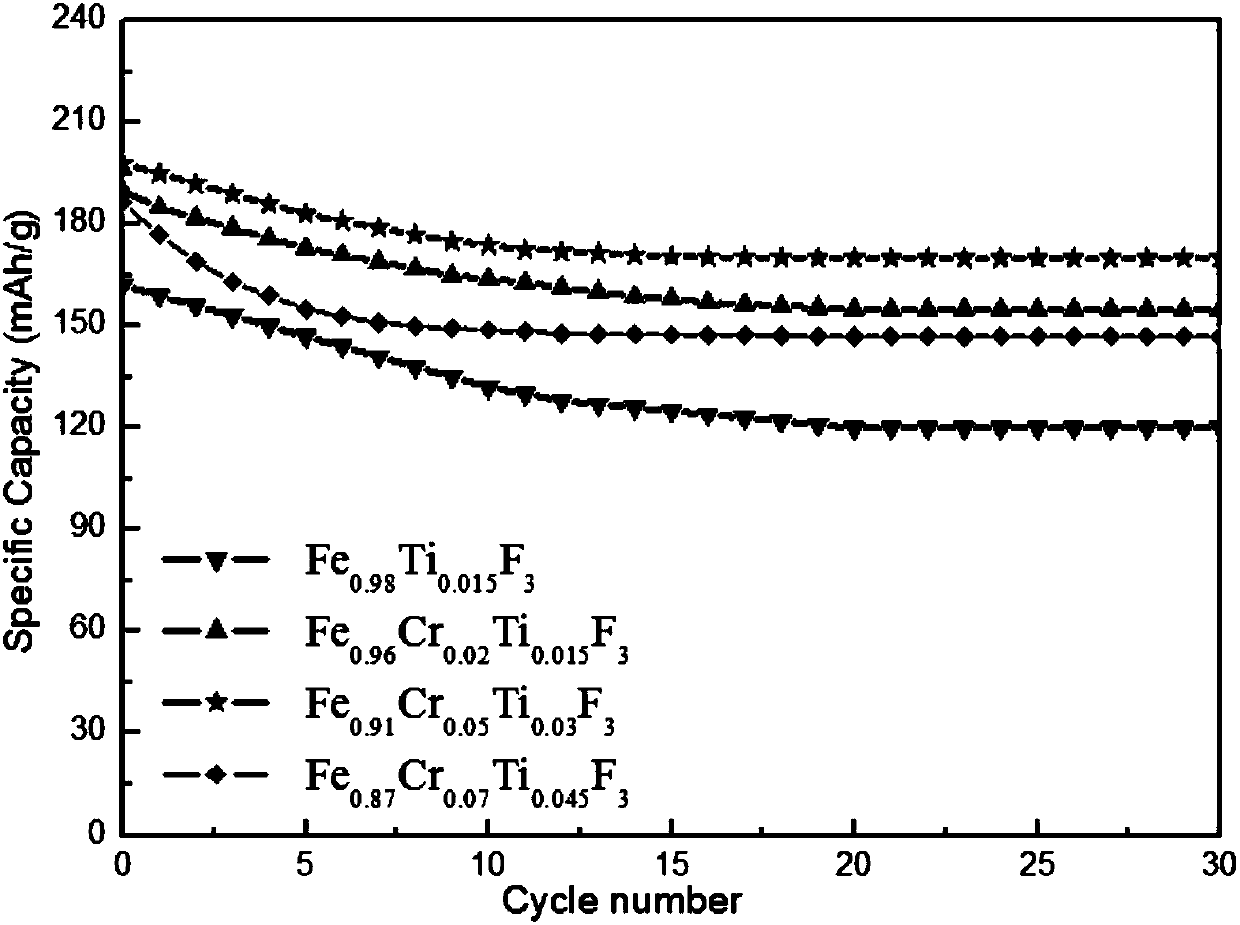

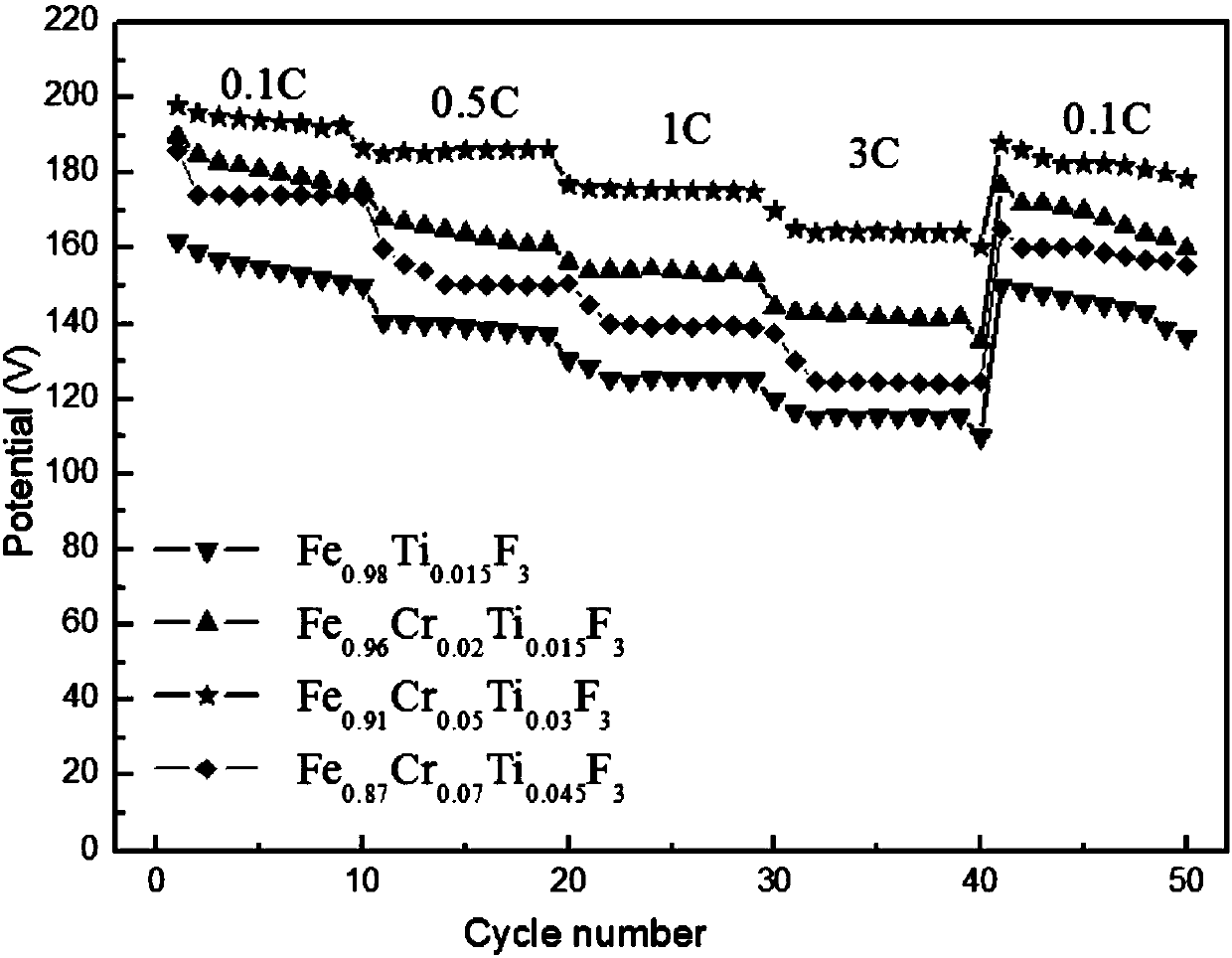

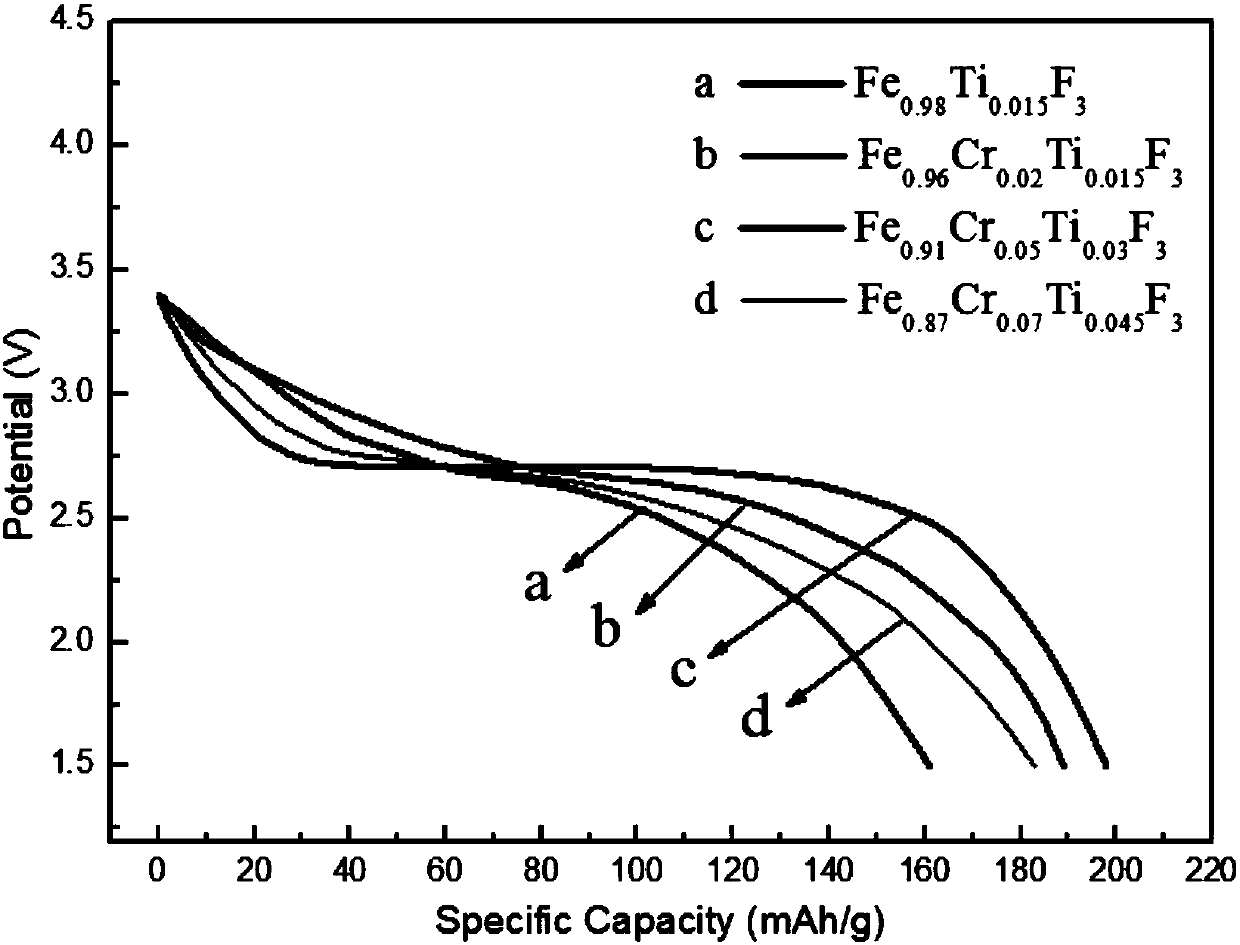

A lithium-ion battery and composite material technology, which is applied in the field of Ti4+, Cr3+-doped ferric trifluoride composite material and its preparation, can solve the problems of poor stability, poor conductivity and dynamic properties of ferric fluoride materials, and material rate performance low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention provides a doped Ti 4+ 、Cr 3+ The preparation method of ferric trifluoride composite material, comprises the following steps:

[0054] A) After mixing and grinding trivalent iron source, tetravalent titanium source, trivalent chromium source, fluoride, alcohol solution and grinding aids, a semi-finished composite material is obtained;

[0055] B) After heat-treating the composite material semi-finished product obtained in the above steps, doped Ti 4+ 、Cr 3+ ferric trifluoride composite material.

[0056] The invention first mixes and grinds trivalent iron source, tetravalent titanium source, trivalent chromium source, fluoride, alcohol solution and grinding aid to obtain a composite material semi-finished product. In the present invention, the selection range and sources of the trivalent iron source, tetravalent titanium source, trivalent chromium source, and fluoride are preferred principles. 4+ 、Cr 3+ The raw materials in the ferric trifluoride com...

Embodiment 1

[0072] The doped Ti prepared in this embodiment 4+ 、Cr 3+ FeF 3 The chemical formula of the nanocomposite cathode material is Fe 0.96 Cr 0.02 Ti 0.015 f 3 .

[0073]Weigh iron nitrate, chromium chloride, titanium nitrate and ammonium fluoride according to the molar amounts of Fe, Cr, Ti and F in the above chemical formula, carry out batching, obtain mixture one after mechanical grinding, then mix mixture one and grinding aid SiC Mix again according to the mass ratio of 1:0.02 to obtain mixture 2, and add enough dispersant ethanol solution to immerse mixture 2 and mix evenly to obtain the final mixture.

[0074] Put the final mixture obtained in the above steps at room temperature and under the protection of nitrogen in a high-energy ball mill at a speed of 250r / min. After ball milling for 10 hours, take out the material, and then put it into a vacuum tube-type atmosphere furnace protected by argon to raise the temperature to 300°C. After cooling at constant temperature ...

Embodiment 2

[0081] The doped Ti prepared in this embodiment 4+ 、Cr 3+ FeF 3 The chemical formula of the nanocomposite cathode material is Fe 0.91 Cr 0.05 Ti 0.03 f 3 .

[0082] Weigh iron nitrate, chromium chloride, titanium nitrate and ammonium fluoride according to the molar amounts of Fe, Cr, Ti and F in the above chemical formula, carry out batching, obtain mixture one after mechanical grinding, then mix mixture one and grinding aid SiC Mix again according to the mass ratio of 1:0.03 to obtain mixture 2, and add enough dispersant ethanol solution to immerse mixture 2 and mix evenly to obtain the final mixture.

[0083] Put the final mixture obtained in the above steps at room temperature and under the protection of nitrogen in a high-energy ball mill at a speed of 350r / min. After ball milling for 15 hours, take out the material, and then put it into a vacuum tube-type atmosphere furnace protected by argon to heat up to 350°C. After cooling at constant temperature for 6 hours, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com