Sour and sweet sliced cold chicken dipping condiment and preparation method thereof

A sweet and sour, dipping technology, applied in the direction of food ingredients as taste improver, food ingredients as taste improver, food science, etc., can solve problems such as weak taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

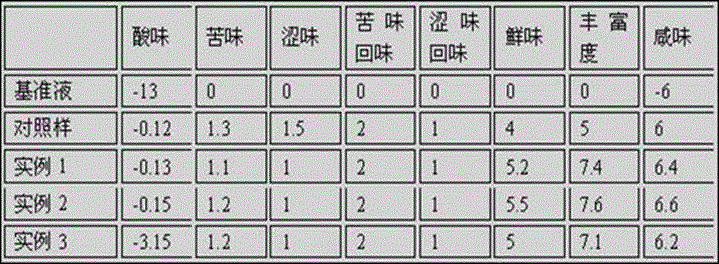

Examples

Embodiment 1

[0023] A sweet and sour chicken dipping sauce, mainly composed of the following raw materials in parts by weight: 5 parts of ginger; 7 parts of garlic; 4 parts of gongsun orange; 4 parts of shallot; 4 parts of coriander; 8 parts of sugar; 7 parts of edible oil, its preparation method comprises the following steps:

[0024] (1) Degreasing: Use ultraviolet light to irradiate sand ginger, garlic and Gongsun orange respectively for two hours, then send them to the rotating cleaning roller brush for cleaning, spray with cleaning water, pick up and drain; drain the dried sand Ginger, garlic, and gongsun orange are sent to the acupuncture-type degreasing machine, so that the oil in the sand ginger peel, garlic peel and orange peel escapes from the oil bubbles, and then the oil is removed by a butterfly centrifugal separator to obtain degreasing Sand ginger, garlic and gongsun orange; among them, the working oil temperature of the butterfly centrifuge is 40°C, and the drum speed is 75...

Embodiment 2

[0032] With above-mentioned embodiment 1, its difference is mainly to be made up of the raw material of following parts by weight: 6 parts of sand ginger; 8 parts of garlic; 5 parts of Gongsun orange; 6 parts of shallot; 11 parts of reducing sugar; 9 parts of edible oil. During its preparation:

[0033] The rotating drum speed of the butterfly centrifuge in step (1) is 8000r / min;

[0034] In step (3), the baking temperature is 125°C, and the baking time is 2 minutes;

[0035] In step (5), the screen mesh number is 60 mesh; under the homogeneous pressure of 35Mpa;

[0036] In step (6), the temperature was raised to 95°C within 20s and kept for 15s.

Embodiment 3

[0038] With above-mentioned embodiment 1, its difference is mainly to be made up of the raw material of following parts by weight: 4 parts of sand ginger; 5 parts of garlic; 2 parts of Gongsun orange; 3 parts of shallot; 5 parts of reducing sugar; 4 parts of cooking oil. During its preparation:

[0039] The drum speed of the butterfly centrifuge in step (1) is 7000r / min;

[0040] In step (3), the baking temperature is 105°C, and the baking time is 4 minutes;

[0041] In the step (5), the screen mesh number is 30 mesh; under the homogeneous pressure of 20Mpa;

[0042] In step (6), the temperature was raised to 93°C within 15s and kept for 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com