A preparation method of bacterial cellulose membrane tissue engineering artificial tendon scaffold

A technology of bacterial cellulose membrane and artificial tendon is applied in the field of tissue engineering materials, which can solve the problems of high technical difficulty and achieve the effects of good mechanical properties and good cell compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

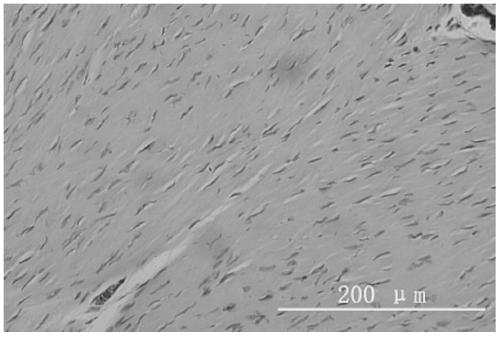

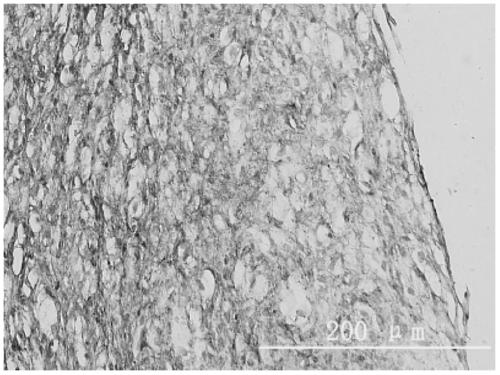

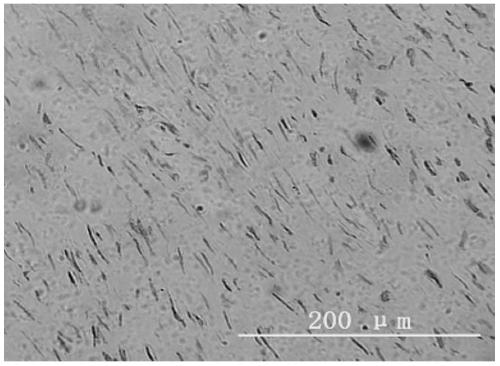

Image

Examples

Embodiment 1

[0041] 1. Preparation of BC membrane

[0042] (1) Preparation

[0043] 1. Gluconacetobacter xylosus ( Glucoacetobacter xylinus ) strains inoculated into the solid medium for routine activation, select the activated strains from the solid medium, put them into a 500ml Erlenmeyer flask containing 100ml of liquid medium, and place them on a shaker at 28°C and 160r / min Cultivate for 24-32 hours to make Gluconacetobacter xylosus seed solution for later use.

[0044]2. Gluconoacetobacter xylosus seed liquid is inoculated with 8% volume per liter of distiller's grain degradation liquid compound liquid, inserted into the distiller's grain degradation liquid compound liquid, fully shaken to make the bacteria liquid uniform, and then placed at 28°C Static culture in an incubator. After culturing for 5 days, it can be seen that a bacterial cellulose film floats on the surface of the liquid culture medium, and the thickness of the bacterial cellulose film is 3.1mm at this time.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com