Precious metal platinum nanometer catalyst and preparation method and application thereof

A technology of catalysts and precious metals, applied in the field of noble metal platinum nano-catalysts with high-temperature anti-sintering performance and its preparation, can solve the problems of easy agglomeration and deactivation of platinum nanocrystals, limited applications, etc., and achieve the effect of wide application range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

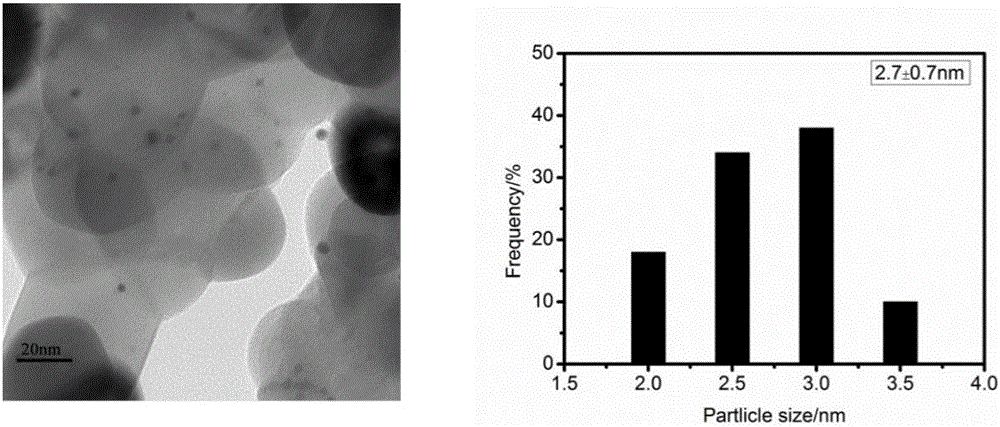

[0037] Preparation of 3-5nm Pt particles

[0038] a. First, preheat 4 mL of ethylene glycol at 110°C for 30 minutes.

[0039] b. Dissolve PVP (Mw≈55000) in 2 mL of ethylene glycol to a concentration of 11.3 mg / mL.

[0040] c. Dissolve chloroplatinic acid in 2 mL of ethylene glycol to a concentration of 8.3 mg / mL.

[0041] d. Simultaneously inject 0.5 mL of each of the two solutions in steps b and c into the ethylene glycol in step a at an injection rate of 0.67 mL / min. The reaction was continued at 110° C. for 0.5-1 h, and cooled to room temperature naturally. The resulting Pt suspension was a clear gray color and the product was not washed by centrifugation.

[0042] Carrier α-Fe 2 o 3 Synthesis

[0043] a. Disperse PVP in 3mL of ethanol solvent with a concentration of 0.13g / mL; add 3.5mL of glacial acetic acid; then add iron acetylacetonate (Fe(acac) 3 ), and a spinning precursor solution with a concentration of 0.12 g / mL was prepared.

[0044] b. Transfer the spinni...

Embodiment 2

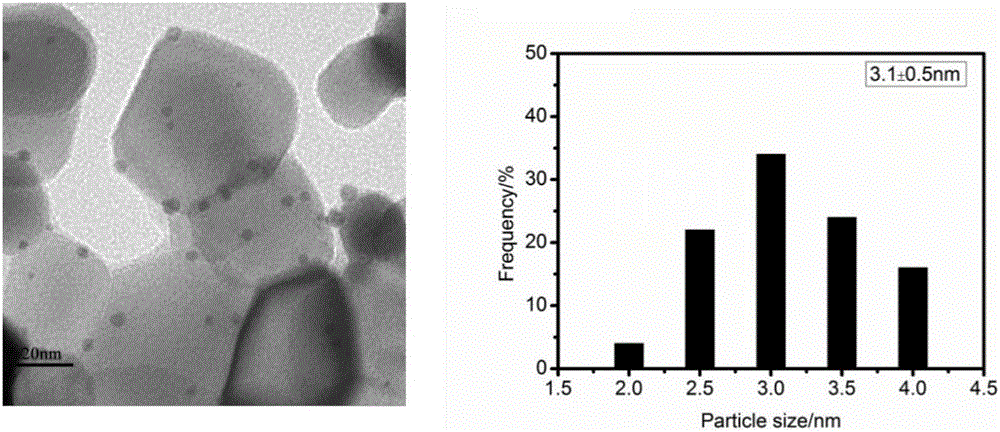

[0053] a. the α-Fe in embodiment 1 2 o 3 The particles were dispersed in ethanol to obtain a suspension with a concentration of 1 mg / mL.

[0054] b. according to the Pt suspension and Fe obtained in Example 1 2 o 3 The volume ratio of the suspension is 1:10. Take out the Pt suspension and disperse it in the mixed solution of ethanol and water with a volume ratio of 4:1.

[0055] c. Mix the suspension of step a with the mixed solution obtained in step b, stir at room temperature for 2 hours, and Pt is supported on Fe 2 o 3 surface of the particles, to obtain the catalytic precursor Pt / Fe 2 o 3 .

[0056] d. The catalytic precursor Pt / Fe in step c 2 o 3 Disperse in PVP (Mw≈55000) ethanol solution with a concentration of 6mg / mL, use a vortex mixer to help dissolve, and obtain a suspension with a concentration of 0.5mg / mL, the catalytic precursor Pt / Fe 2 o 3 Mixed with graphene oxide (GO) at a volume ratio of 1:1, the catalytic precursor Pt / Fe 2 o 3 uniformly disperse...

Embodiment 3

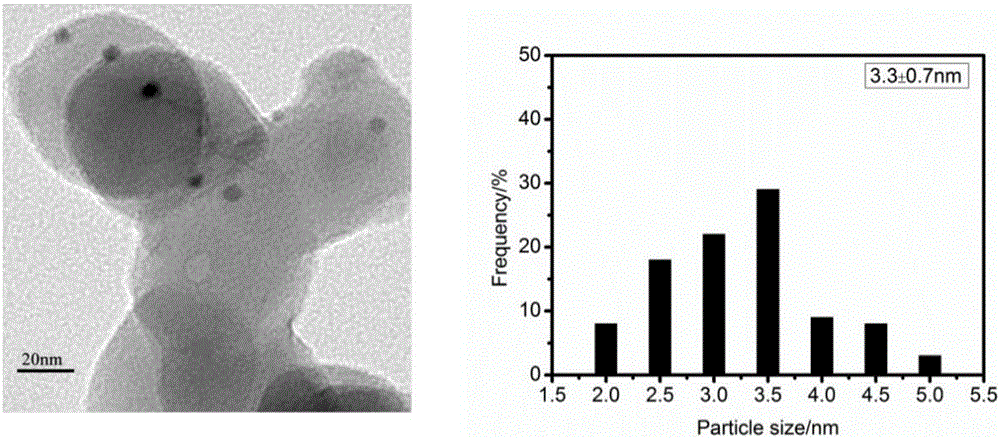

[0058] a. the α-Fe in embodiment 1 2 o 3 The particles were dispersed in ethanol to obtain a suspension with a concentration of 1 mg / mL.

[0059] b. according to the Pt suspension and Fe obtained in Example 1 2 o 3 The volume ratio of the suspension is 1:10. Take out the Pt suspension and disperse it in the mixed solution of ethanol and water with a volume ratio of 4:1.

[0060] c. Mix the suspension of step a with the mixed solution obtained in step b, stir at room temperature for 2 hours, and Pt is supported on Fe 2 o 3 surface of the particles, to obtain the catalytic precursor Pt / Fe 2 o 3 .

[0061] d. The catalytic precursor Pt / Fe in step c 2 o 3 Disperse in PVP (Mw≈55000) ethanol solution with a concentration of 6mg / mL, use a vortex mixer to help dissolve, and obtain a suspension with a concentration of 0.5mg / mL, the catalytic precursor Pt / Fe 2 o 3 Mixed with graphene oxide (GO) at a volume ratio of 1:1, the catalytic precursor Pt / Fe 2 o 3 uniformly disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com