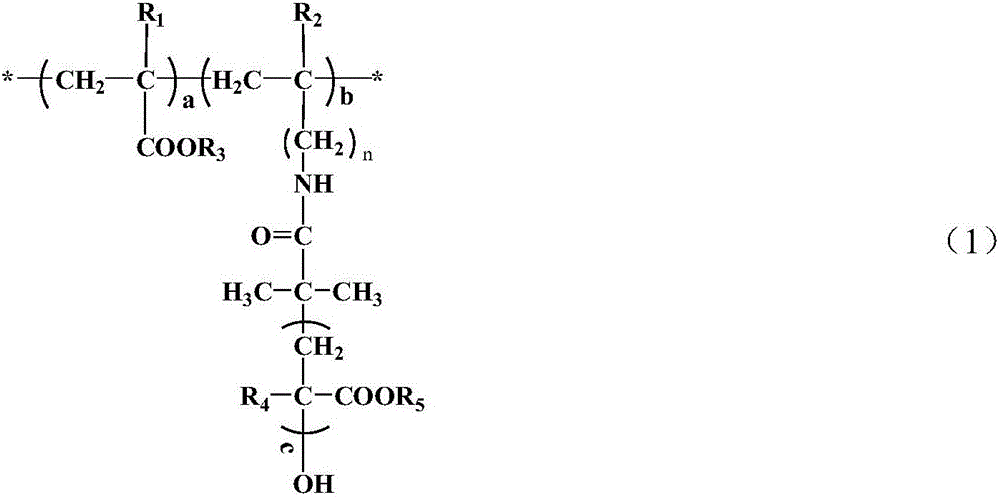

Preparation method of super-high-dispersion polycarboxylate-type efficient water reducing agent

A high-efficiency water reducer, polycarboxylate technology, applied in the field of polycarboxylate water reducer for cement concrete, can solve the problems of complex preparation engineering process, very industrialized production, harsh reaction conditions, etc., and achieve rich sources , quick and efficient response, and mature methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

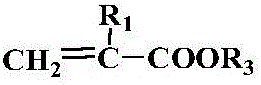

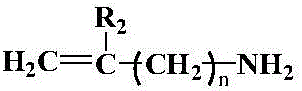

Method used

Image

Examples

Embodiment 1

[0037]1) Preparation of amino-terminated copolymers: 10 mol of 2-methacrylamine and 2 mol of methyl acrylate were subjected to oxidation-reduction radical polymerization at 25° C. for 30 minutes under 0.01 mol of mercaptoacetic acid to obtain copolymers containing terminal amines. The weight-average molecular weight of the amino-terminated copolymer product is 3000;

[0038] 2) Preparation of unsaturated halogen-terminated copolymers: 10 mol of amine-terminated copolymers obtained in step 1) and 30 mol of 2-bromoisobutyryl bromide were subjected to an esterification reaction at 0°C for 90 minutes to obtain halogen-terminated copolymers ;

[0039] 3) Preparation of super-dispersive water reducer: the copolymerization product of 10mol terminal halogen group obtained in step 2), 50mol butyl methacrylate, 0.01mol CuBr and 0.02mol pentamethyldiethylenetriamine (PMDETA) 50 After reacting at ℃ for 240 minutes, a super-dispersed polycarboxylate superplasticizer can be obtained. The p...

Embodiment 2

[0042] 1) Preparation of amino-terminated copolymers: 10 mol of allylamine and 2.5 mol of ethyl acrylate were subjected to oxidation-reduction free radical polymerization at 30°C for 35 minutes under the action of 0.1 mol of 2-mercaptopropionic acid to obtain copolymers containing terminal amines. The weight-average molecular weight of the amine-based copolymerization product is 3500;

[0043] 2) Preparation of unsaturated halogen-terminated copolymers: 10 mol of amine-terminated copolymers obtained in step 1) and 40 mol of 2-bromoisobutyryl chloride were subjected to an esterification reaction at 5° C. for 80 minutes to obtain halogen-terminated copolymers;

[0044] 3) Preparation of super-dispersive water reducer: react the 10mol terminal halogen copolymer obtained in step 2), 250mol hydroxyethyl acrylate, 0.03mol CuCl, and 0.02mol HMTETA at 55°C for 200 minutes to obtain a super-dispersive type Polycarboxylate superplasticizer, the polycarboxylate high-efficiency water redu...

Embodiment 3

[0047] 1) Preparation of amino-terminated copolymers: 10mol 3-methyl-2-butene-1-amine and 3mol propyl acrylate were subjected to oxidation-reduction free radical polymerization at 35°C under the action of 0.04mol 3-mercaptopropionic acid 40min obtains the copolymerization product containing terminal amino group, and the weight-average molecular weight of the terminal amino group copolymerization product is 4000;

[0048] 2) Preparation of unsaturated halogen-terminated copolymers: 10 mol of amine-terminated copolymers obtained in step 1) and 50 mol of 2-chloroisobutyryl chloride were subjected to an esterification reaction at 10° C. for 70 minutes to obtain halogen-terminated copolymers;

[0049] 3) Preparation of super-dispersive water reducer: the copolymerization product of 10mol terminal halogen group obtained in step 2), 300mol hydroxypropyl acrylate, 0.05mol CuBr, 0.1mol tetrakis [(2-pyridyl) methyl] ethyl Diamine (TPEN) was reacted at 60°C for 180 minutes to obtain a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com