A composite material sewing thread for sewing polyphenylene sulfide filter bags

A technology of polyphenylene sulfide and composite materials, which is applied in the field of special sewing thread, can solve the problems of filter bag sewing pinhole dust leakage, poor recovery, troubled filter bag manufacturers, etc., to achieve the prevention of filtration efficiency and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

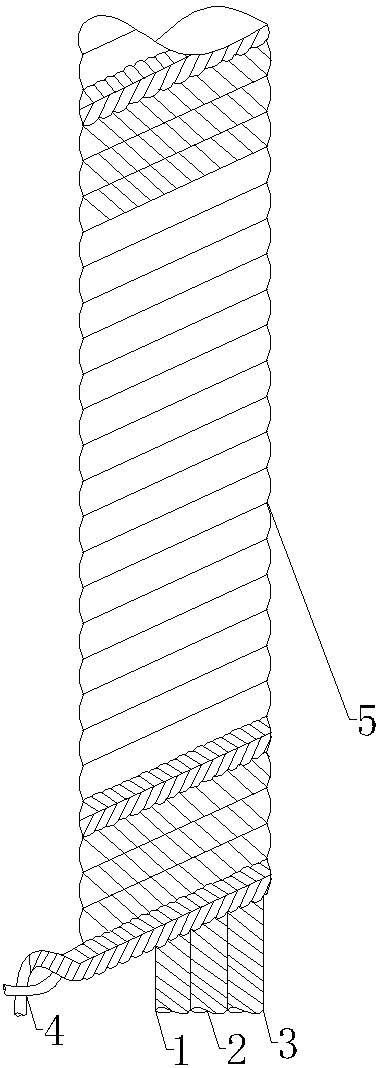

[0021] Step 1. Use three 440dtex polytetrafluoroethylene pastes to extrude monofilaments, and twist the monofilaments with a twist of 420T / m and a twist direction of "S", and twist them into polytetrafluoroethylene monofilaments 1, 2 and 2 3; Use a 20Nm two-ply polyphenylene sulfide yarn 4, single yarn twist 520T / m, ply twist 500T / m, both "S" twist. The polyphenylene sulfide yarn is carded and spun with 2dtex and 51mm length polyphenylene sulfide fiber.

[0022] Step two, the above three polytetrafluoroethylene monofilaments and polyphenylene sulfide yarn are twisted and twisted 5, and the twist is 480T / m, Z twist.

[0023] Step 3: After the above-mentioned polytetrafluoroethylene monofilament and polyphenylene sulfide yarn are twisted and twisted, they are wound into a shaft, and then the thread is covered by a gluing device to form a uniform co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com