Rubber and plastic composite insulating pipe bus and manufacturing method thereof

A technology of composite insulation and pipe busbar, which is applied in the direction of insulated cables, insulated conductors, cable/conductor manufacturing, etc., and can solve the problems of poor tear resistance, short length, large damage to insulation layer and conductor tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

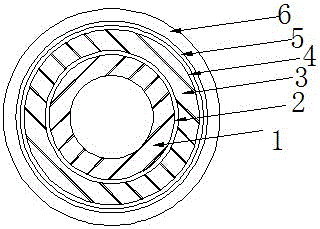

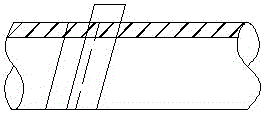

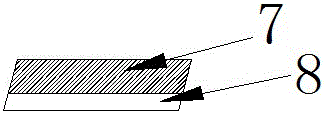

[0021] figure 1 What is shown is a rubber-plastic composite insulating pipe busbar, including: conductor pipe 1, conductor shielding layer 2, composite insulating layer 3, insulating shielding layer 4, grounding layer 5 and outer sheath layer 6; wherein the conductor shielding layer 2 It is made of a semi-conductive shielding material evenly coated on the outside of the conductor tube 1; the composite insulating layer 3 is a composite strip made of cross-linked polyethylene insulating tape as the base material and liquid silicone rubber, and its composite structure is as follows image 3 As shown, the composite tape is used on the surface of the conductor shielding layer 2 to figure 2 The circular and equal-pitch overlap shown in the figure is evenly wound to the design size; the insulating shielding layer 4 is made of a semi-conductive shielding material evenly coated on the outside of the composite insulating layer 3; the grounding layer 5 is made of copper tape and figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com