Preparation method of improving semiconductor laser reliability

A laser and semiconductor technology, applied to the structure of the active region, etc., can solve the problems of semiconductor laser lateral light mode disorder, laser transverse mode and longitudinal mode change, etc., to achieve easy operation, improve device reliability, and increase COD threshold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The epitaxial layer of the selected chip is a GaAs / GaInP selective etching material structure. The semiconductor laser tube core resonator has a length of 1500 μm and a width of 500 μm, a ridge waveguide width of 100 μm, and double grooves on both sides of the ridge. The double-groove ridge waveguide is fabricated by method of etching.

[0046] A preparation method for improving the reliability of a semiconductor laser, which adopts one-time etching to simultaneously remove the ohmic contact layer other than the ridge-shaped mesa of the semiconductor laser, and introduces a non-implantation region window structure; the preparation method for improving the reliability of the semiconductor laser includes specific steps as follows :

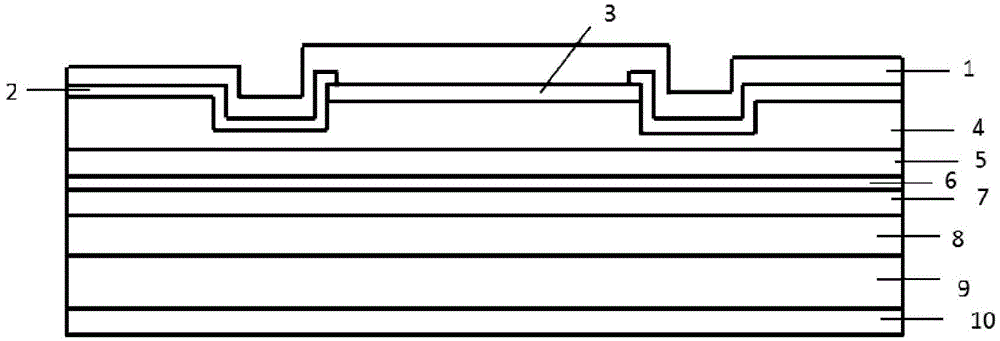

[0047] (1) On the substrate 9, grow an N-type lower confinement layer 8, a lower waveguide layer 7, an active region 6 with a quantum well structure, an upper waveguide layer 5, a P-type upper confinement layer 4, and an ohmic contact layer 3...

Embodiment 2

[0059] A kind of preparation method that improves the reliability of semiconductor laser as described in embodiment 1, its difference is that,

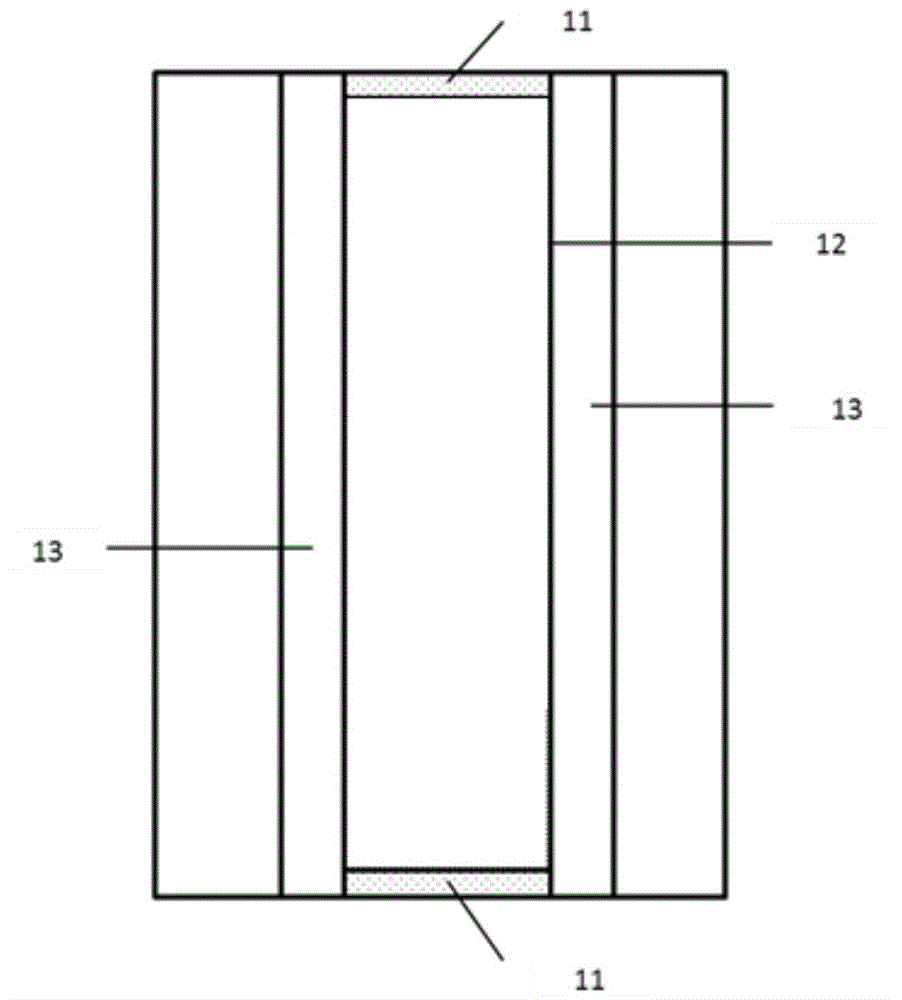

[0060] In steps (1)-(2), the window of the quantum well mixed region is prepared on the epitaxial wafer, and the active region of the window region is mixed by zinc expansion or other methods; wherein the non-implanted region window structure 11 is engraved on the quantum well In the center of the window in the cluttered area.

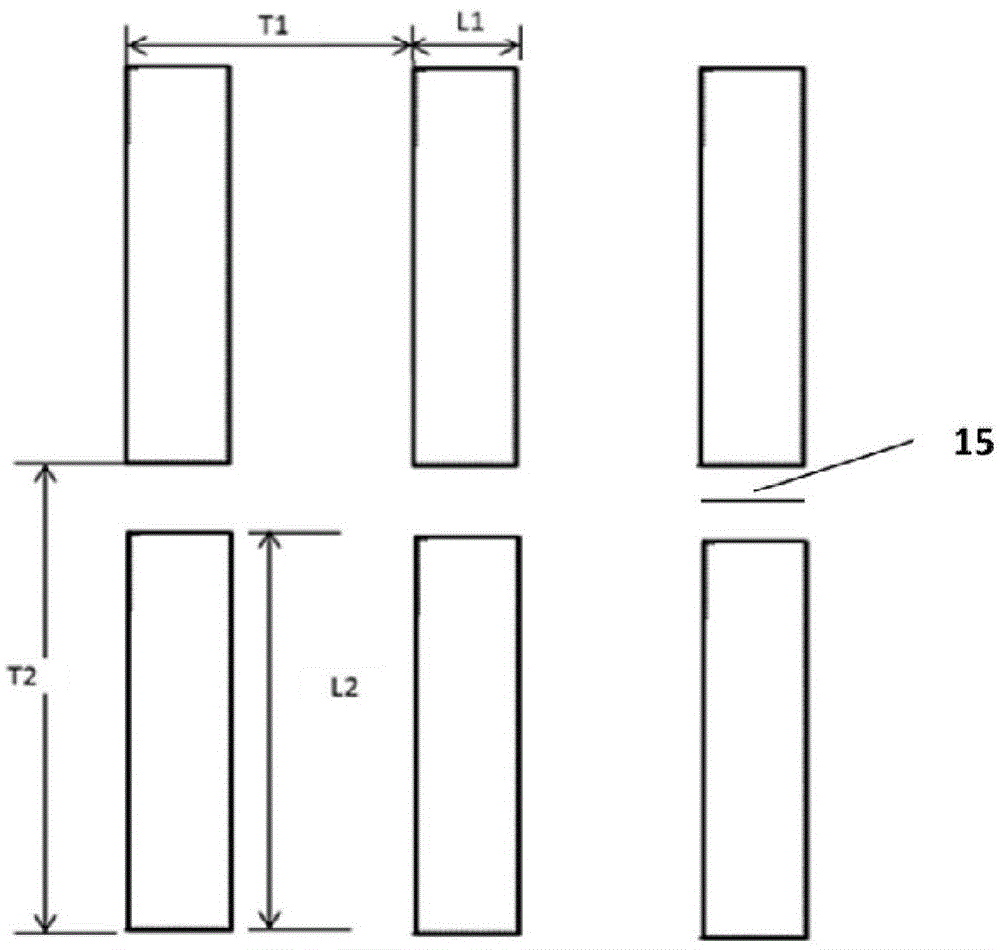

[0061] On the epitaxial wafer, a rectangular pattern arranged periodically is photo-etched, wherein the length L2 of the rectangular pattern is 1450 μm, the width L1 is 120 μm, the longitudinal period T2 is 1500 μm, and the lateral period T1 is 500 μm; the ohmic contact layer outside the rectangular pattern is removed by etching , exposing the P-type upper confinement layer, removing the ohmic contact layer other than the ridge-shaped mesa and introducing the non-implantation region window structure 11; wherei...

Embodiment 3

[0063] A preparation method for improving the reliability of a semiconductor laser as described in Example 1, the difference is that the selected chip epitaxial layer is a non-selective etching material structure of GaAs / AlGaAs, when the ohmic contact layer and the P-type The two-layer structure of the confinement layer is non-selective etching, or the ridge mesa is directly prepared by dry etching, then the size of the rectangular figure is: the width L1 of the rectangular figure ≤ the width of the ridge mesa of the semiconductor laser, the length of the rectangular figure L2 = (the resonant cavity length of the semiconductor laser chip - the width of the window structure in the non-implanted region). The length of the semiconductor laser die resonator is 2000 μm, the width is 500 μm, the width of the ridge waveguide is 200 μm, and the width of the double grooves on both sides of the ridge is 30 μm. The double groove ridge waveguide is made by wet etching method.

[0064] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com