Preparation method and application of nanometer sustained release sodium butyrate for feed of grass carp

A technology for slow-release sodium butyrate and grass carp feed is applied in the molding or processing, application, animal feed and other directions of animal feed, which can solve the problems of non-sustainability, unsatisfactory dissolution and release effect, and immature technology. Easy to implement, improve absorption, increase the effect of breeding production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

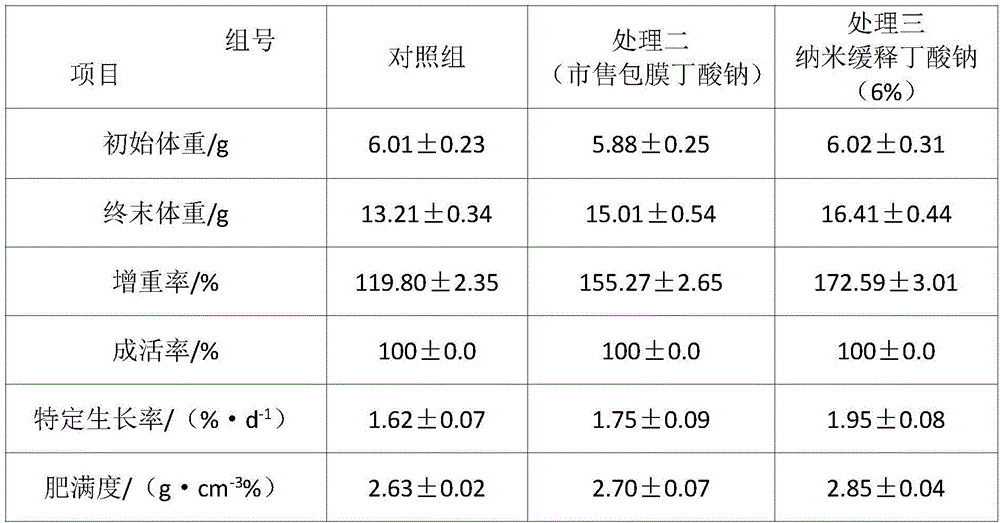

[0021] Embodiment 1: use nano slow-release sodium butyrate for grass carp feed of the present invention, adopt following technical process to carry out grass carp indoor cultivation, obtain better effect.

[0022] (1) Weigh 40g of sodium hydroxide, dissolve it in 1000ml of water, add 40g of n-butyric acid evenly dropwise, react for 2.0 hours after the dropwise addition, add 150g of auxiliary materials, and spray dry at 220°C to obtain nano-sustained-release sodium butyrate.

[0023] (2) The excipients consist of 2 parts of beeswax, 2 parts of palm wax, 0.3 parts of fish oil, 4 parts of polyethylene glycol, 0.8 parts of filler, and 1.5 parts of nano sustained-release carrier.

[0024] (3) Wherein the preparation method of the nano-sustained-release carrier is: weigh 2.0054g dry polyethylene glycol 4000, add 3.00mL polycaprolactone and 0.2mL stannous octoate, cool in liquid nitrogen, vacuumize, and pass nitrogen gas Oxygen was exhausted, and the reaction was stirred at 135°C for...

Embodiment 2

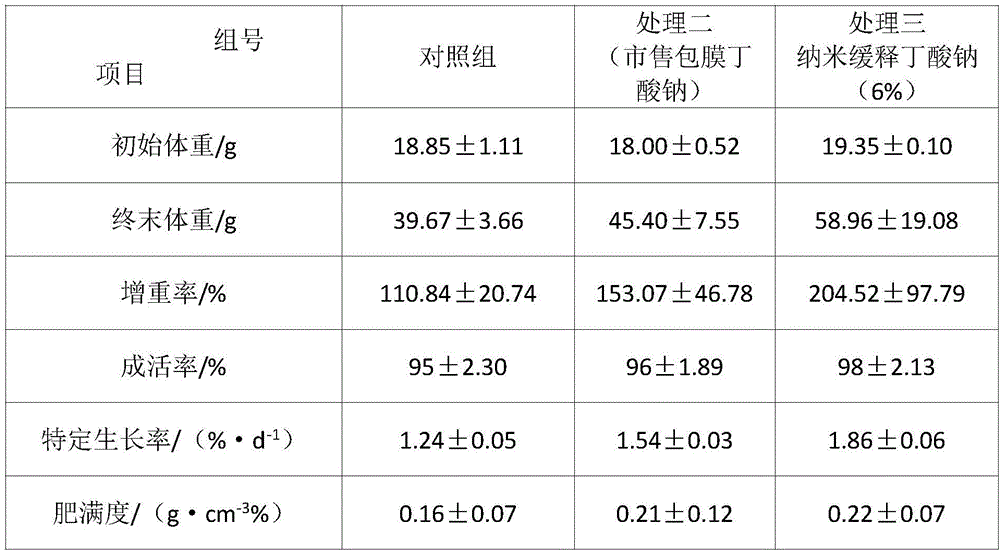

[0029] Embodiment 2: use the nano slow-release sodium butyrate for grass carp feed of the present invention, adopt the following technical process to carry out grass carp cage culture, and obtain better results.

[0030] (1) Weigh 40g of sodium hydroxide, dissolve it in 1000ml of water, add 60g of n-butyric acid evenly dropwise, react for 2.0 hours after the dropwise addition, add 200g of excipients, and spray dry at 220°C to obtain nano-sustained-release sodium butyrate.

[0031] (2) The excipients consist of 2.5 parts of beeswax, 1.5 parts of palm wax, 0.5 parts of fish oil, 3 parts of polyethylene glycol, 1 part of filler, and 1.5 parts of nano sustained-release carrier.

[0032] (3) Wherein the preparation method of the nano-sustained-release carrier is: weigh 2.0054g dry polyethylene glycol 4000, add 3.00mL polycaprolactone and 0.2mL stannous octoate, cool in liquid nitrogen, vacuumize, and pass nitrogen gas Oxygen was exhausted, and the reaction was stirred at 135°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com