Blueberry natto product

A blueberry and natto technology, applied in the directions of food ingredients, food adsorption, food extraction, etc., can solve the problems of heavy ammonia odor, poor edibility, and difficult preservation, etc., and achieves improvement of color, accelerated autolysis, and improved natto flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

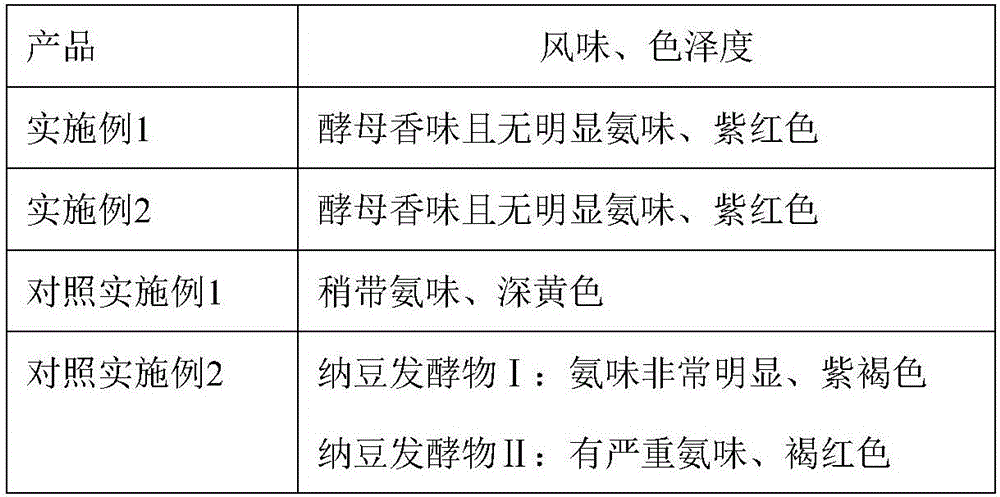

Examples

Embodiment 1

[0038] 200 kg of non-rotten blueberry raw materials are selected, washed, air-dried at 45-55° C. to control the water content of the blueberries at 30-40 percent, and the blueberries are mashed and beaten to obtain blueberry pulp. Take 150L of blueberry pulp, add 300L of 70% ethanol aqueous solution, adjust the pH value to 4.5 with 0.1mol / L hydrochloric acid, ultrasonically extract for 48 hours, filter with 3 layers of gauze, repeat twice, combine the filtrates, and obtain the blueberry pomace for later use. The obtained filtrate was concentrated under reduced pressure below 50°C to 1 / 30 of the original volume, adsorbed on XDA-8 macroporous resin, carried out gradient elution with 12BV of 40-80% ethanol aqueous solution, collected the eluate, and washed The deliquored liquid was concentrated to dryness under reduced pressure below 50°C to obtain blueberry pigment.

Embodiment 2

[0040] Take 100kg of blueberry pomace, add 7kg of sucrose, sterilize at 100-110°C for 30 minutes, inoculate 3kg of baker's yeast powder after cooling, ferment aerobically at 25-28°C for 4 days, and store at a low temperature of 4°C to obtain blueberry fermented product . Select 100kg of dry soybeans without insect infestation and mildew, put them into 50L of water for soaking, the soaking temperature is 45°C, and the soaking time is 180min. Cooked, must steam boiled soybeans (cooked until the soybeans are fully cooked). 200kg of steamed soybeans were inoculated with 20L of Bacillus natto seed liquid and fermented aerobically at 38-42°C for 48 hours to obtain soybean fermented product; then 100kg of blueberry fermented product was added thereto, and after aerobic fermentation was continued at 38-42°C for 20 hours, Get natto fermented product. Add 3kg of dry ginger powder, 4kg of salt and 5kg of star anise powder to the natto fermented product to mix, then add 20kg of blueberr...

Embodiment 3

[0042]Take 100kg of blueberry pomace, add 10kg of sucrose, sterilize at 100-110°C for 30 minutes, inoculate 3.5kg of baker's yeast powder after cooling, ferment aerobically at 25-28°C for 3 days, and store at a low temperature of 4°C to obtain fermented blueberries things. Select 300kg of dry soybeans without insect infestation and mildew, and put them into 150L of water for soaking. The soaking temperature is 50°C, and the soaking time is 250min. Cooked, must steam boiled soybeans (cooked until the soybeans are fully cooked). 250kg of steamed soybeans were inoculated with 40L of Bacillus natto seed liquid and fermented aerobically at 38-42°C for 50 hours to obtain soybean fermented product; then 100kg of blueberry fermented product was added thereto, and after aerobic fermentation was continued at 38-42°C for 17 hours, Get natto fermented product. Add 4kg of dry ginger powder, 5kg of salt and 7kg of star anise powder to the natto fermented product to mix, then add 25kg of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com