Preparation method and application of beer yeast polypeptide with high antioxidant activity

A technology of brewer's yeast and oxidation activity, applied in the biological field, can solve the problems of low enzymatic hydrolysis reaction efficiency, unrealized autolysis of waste brewer's yeast, low polypeptide yield, etc., and achieves high hydrolysis efficiency, high product yield, and reduced adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

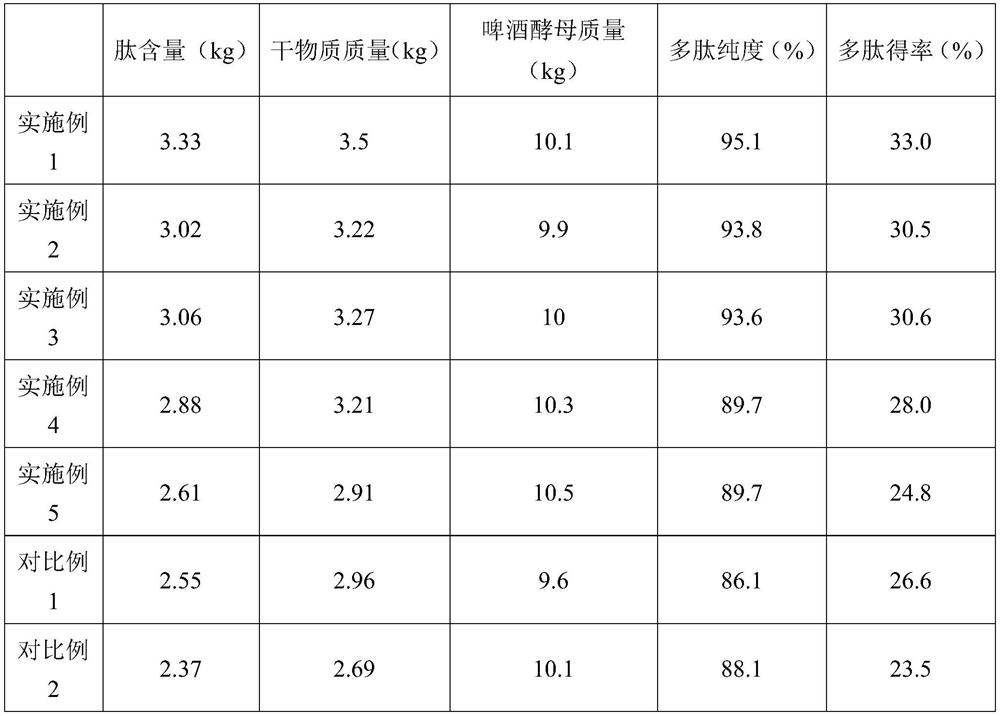

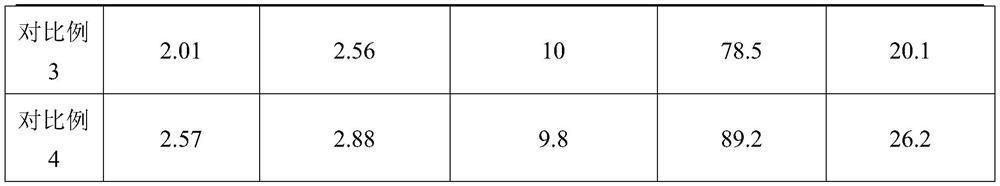

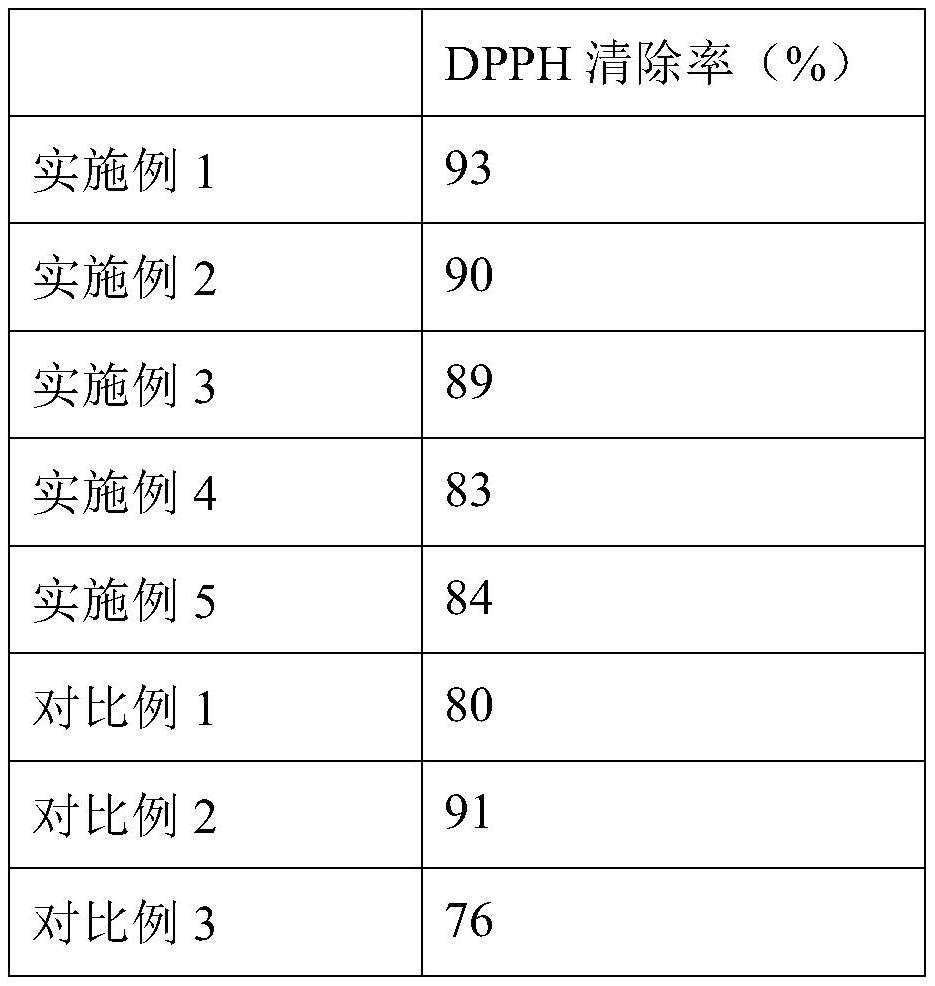

Examples

Embodiment 1

[0037] A method for preparing a beer yeast polypeptide with high antioxidant activity, comprising the following steps:

[0038] (1) brewer's yeast autolysis: brewer's yeast is added 3 times of volume mass percent concentration and is 1% NaHCO 3 Soak in the solution for 60 minutes, centrifuge at 3500r / min for 15 minutes, take the precipitate and add 3 times the volume of sterile water, add flavor protease, react at 45°C for 7 hours, boil for 13 minutes to inactivate the enzyme, then cool to room temperature, then add Lactobacillus acidophilus and maltose, React at 28°C for 24 hours, centrifuge at 15,000r / min for 12 minutes, keep the supernatant, and adjust the pH to 7.0;

[0039] Among them, NaHCO 3 The solution is sterilized after preparation, the added amount of flavor protease is 1.5‰ of the mass of beer yeast, and the added amount of Lactobacillus acidophilus is 5×10 3 -5×10 4 cfu / mL, the amount of maltose added is 8g / L;

Embodiment 2

[0046] A method for preparing a beer yeast polypeptide with high antioxidant activity, comprising the following steps:

[0047] (1) brewer's yeast autolysis: brewer's yeast is added 3 times of volume mass percentage concentration and is 0.1% NaHCO 3 Soak in the solution for 80 minutes, centrifuge at 3000r / min for 20 minutes, take the precipitate and add 3 times the volume of sterile water, add flavor protease, react at 40°C for 8 hours, boil for 15 minutes to inactivate the enzyme, cool to room temperature, then add Lactobacillus helveticus and maltose, React at 35°C for 36 hours, centrifuge at 15,000r / min for 12 minutes, keep the supernatant, and adjust the pH to 6.5;

[0048] Among them, NaHCO 3 The solution is sterilized after preparation, the added amount of flavor protease is 1‰ of the mass of beer yeast, and the added amount of Lactobacillus helveticus is 5×10 3 -5×10 4 cfu / mL, the amount of maltose added is 5g / L;

Embodiment 3

[0055] A method for preparing a beer yeast polypeptide with high antioxidant activity, comprising the following steps:

[0056] (1) brewer's yeast autolysis: brewer's yeast is added 2 times of volume mass percent concentration and is 2% NaHCO 3 Soak in the solution for 30 minutes, centrifuge at 4000r / min for 15 minutes, take the precipitate and add 3 times the volume of sterile water, add flavor protease, react at 50°C for 6 hours, boil for 10 minutes to inactivate the enzyme, cool to room temperature, then add Streptococcus thermophilus and maltose, React at 28°C for 36 hours, centrifuge at 20,000r / min for 8 minutes, keep the supernatant, and adjust the pH to 7.5;

[0057] Among them, NaHCO 3 The solution is sterilized after preparation, the added amount of flavor protease is 2‰ of the mass of beer yeast, and the added amount of Streptococcus thermophilus is 5×10 3 -5×10 4 cfu / mL, the amount of maltose added is 10g / L;

[0058] (2) Enzymolysis: add papain and trypsin to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com