Equipment for harmless processing of container sterilizing gas

A harmless treatment and container technology, which is applied in the pollution prevention and control of fumigation residual gas and the pollution prevention and control of residual fumigant gas in sanitation and detoxification treatment, can solve the problem of time, manpower and logistics costs for import and export enterprises Threats to personal safety, exacerbation of environmental degradation, etc., to reduce the chance of direct contact, reduce time and logistics costs, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

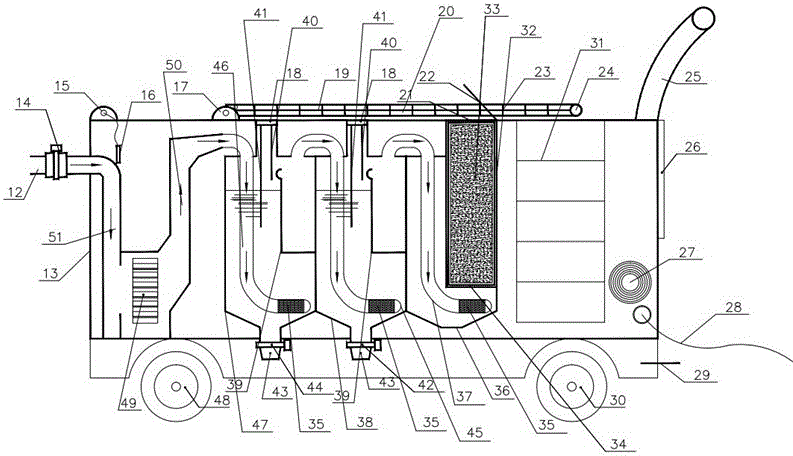

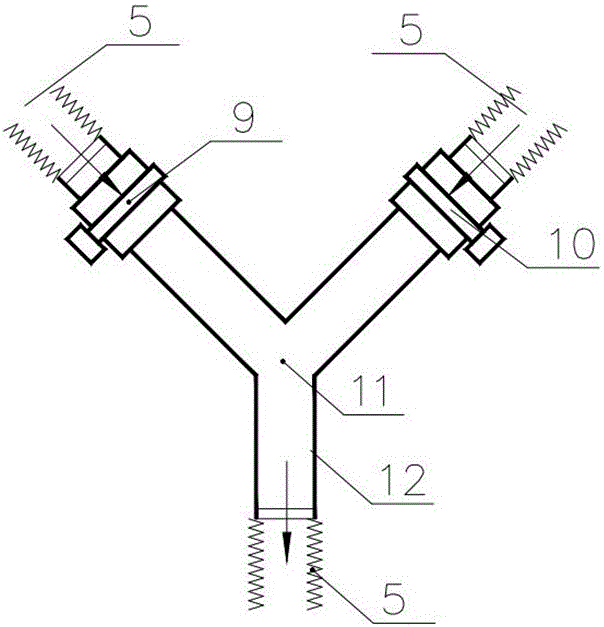

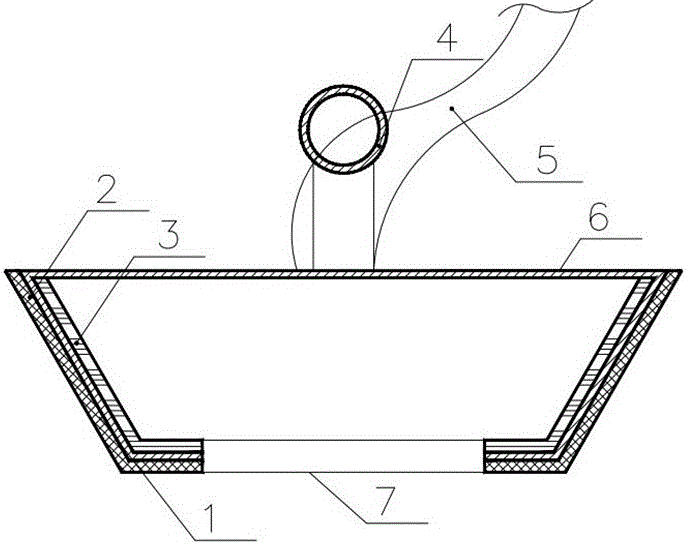

[0026] Working process of the present invention is:

[0027]On-site harmless treatment personnel open the bracket-type climbing ladder (23) and climbing ladder bracket (19) located on the top surface of the fume gas harmless treatment vehicle (13), and place the climbing ladder bracket (19) into a fixed The seat (15) is fixed with a fixed bolt (16). After the power is turned on, the on-site harmless treatment personnel board the fumigant gas harmless treatment vehicle (13) on the top surface of the box body of the fumigant gas harmless treatment vehicle (13) by pedaling the ladder (31), and hold the magnet Hold the handle (4) of the suction suction device (1), stand on the appropriate position of the climbing ladder (20), and align the suction port (7) of the magnetic suction device (1) with one of the containers Or after the magnetic suction device (1) is adsorbed on the side wall of the container behind the two ventilation windows, another on-site harmless treatment personne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com