A kind of arsenic removal agent and its preparation method and application

A technology for removing arsenic and coal-to-synthesis gas, applied in the field of coal chemical industry, can solve problems such as Fischer-Tropsch synthesis, and achieve the effects of reducing other side reactions, high arsenic content, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

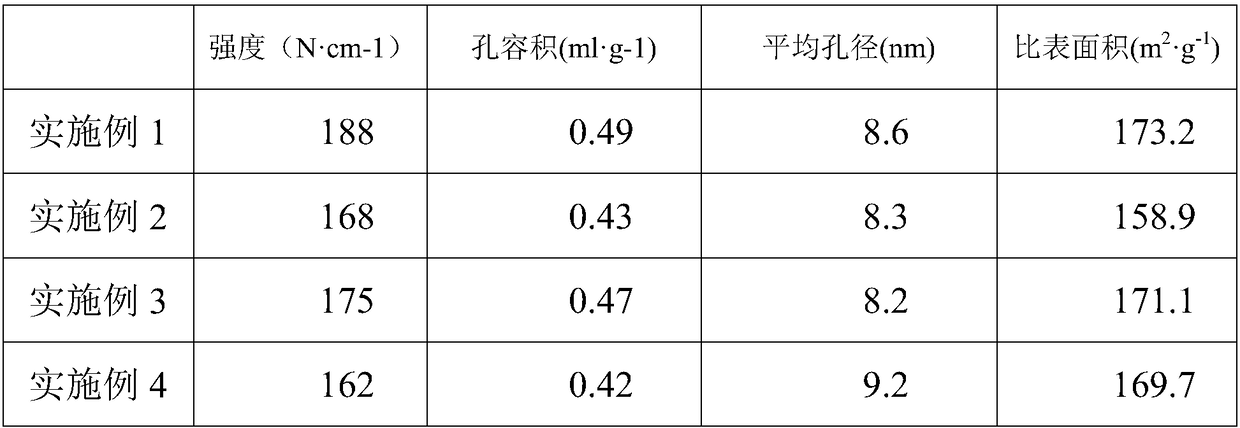

Embodiment 1

[0035] This embodiment provides an arsenic-removing agent and a preparation method thereof. The arsenic removal agent consists of a carrier and an active component loaded on the carrier; the carrier has a specific surface area of 173.2m 2 / g, magnesium aluminum spinel with a crystallinity of 88%, the active component is NiMn 2 o 4 For spinel, the mass ratio of the active component to the carrier is 12:100.

[0036] The preparation method of the arsenic removal agent described in this embodiment comprises the following steps:

[0037] S1, magnesium source-light MgO, aluminum source-Al 2 o 3 ·3H 2 O is kneaded with acidic aqueous solution, and the molar ratio of aluminum source and magnesium source is MgO / Al 2 o 3 The calculation is 1:2, the acidic aqueous solution is nitric acid aqueous solution, the concentration is 2mol / L;

[0038] S2. Adding inorganic additives to the kneaded mixture, ensuring that the mass ratio of the kneaded mixture and the inorganic additives is ...

Embodiment 2

[0043] This embodiment provides an arsenic-removing agent and a preparation method thereof. The arsenic removal agent consists of a carrier and an active component loaded on the carrier; the carrier has a specific surface area of 158.9m 2 / g, magnesia-alumina spinel with crystallinity of 86%, the active component is NiMn 2 o 4 For spinel, the mass ratio of the active component to the carrier is 12:100.

[0044] The preparation method of the arsenic removal agent described in this embodiment comprises the following steps:

[0045] S1. Knead magnesium source-light basic magnesium carbonate, aluminum source-pseudoboehmite and acidic aqueous solution, and the molar ratio of aluminum source and magnesium source is MgO / Al 2 o 3 Calculated as 0.8:2, the acidic aqueous solution is nitric acid aqueous solution, the concentration is 2mol / L;

[0046] S2. Add inorganic additives to the kneaded mixture, ensure that the mass ratio of the kneaded mixture and the inorganic additives is...

Embodiment 3

[0051] This embodiment provides an arsenic-removing agent and a preparation method thereof. The arsenic removal agent consists of a carrier and an active component loaded on the carrier; the carrier has a specific surface area of 171.1m 2 / g, magnesia-aluminum spinel with a crystallinity of 90%, the active component is NiMn 2 o 4 For spinel, the mass ratio of the active component to the carrier is 12:100.

[0052] The preparation method of the arsenic removal agent described in this embodiment comprises the following steps:

[0053] S1, magnesium source-light MgO, aluminum source-Al 2 o 3 ·H 2 O is kneaded with acidic aqueous solution, and the molar ratio of aluminum source and magnesium source is MgO / Al 2 o 3 Calculated as 1.2:1.5, the acidic aqueous solution is nitric acid aqueous solution, the concentration is 2mol / L;

[0054] S2. Adding inorganic additives to the kneaded mixture, ensuring that the mass ratio of the kneaded mixture and the inorganic additives is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com