Preparation method for ultra-coarse spherical tungsten powder

A tungsten powder and spherical technology, applied in the field of preparation of ultra-coarse spherical tungsten powder, can solve the problems of poor fluidity, too fine powder, difficult powder feeding, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] 1. Preparation of precursor powder

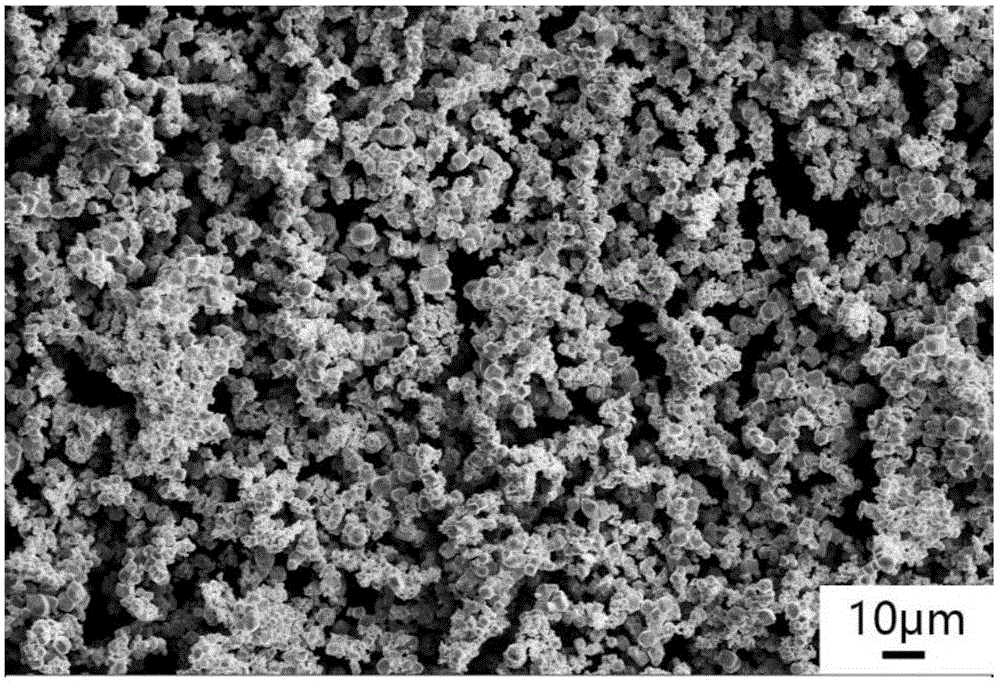

[0025] Using conventional tungsten powder as raw material, granulate through 5wt.% polyvinyl alcohol (PVA) solution, the addition amount is 4wt.%, vacuum dry at 60°C for 1h after granulation, and sieve to obtain precursor powder.

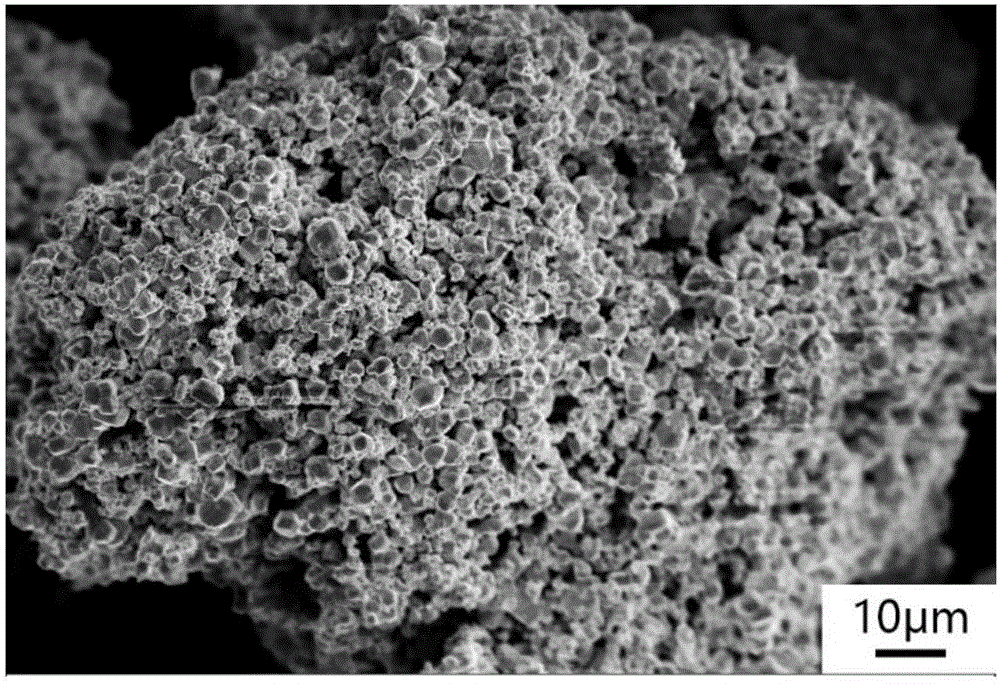

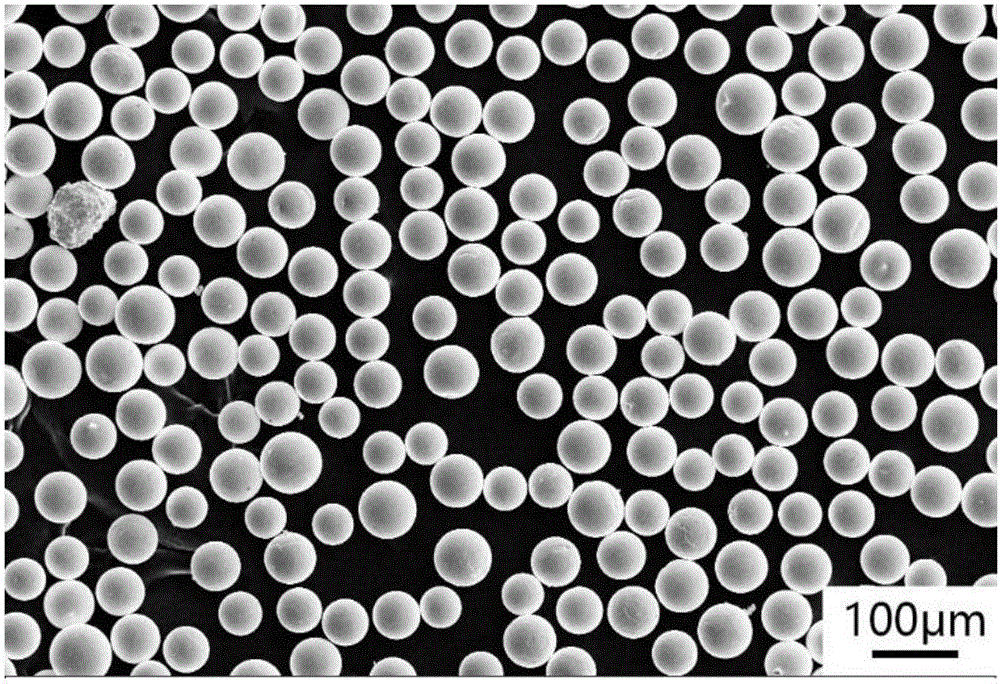

[0026] 2. Preparation of ultra-coarse spherical tungsten powder

[0027] Before the radio frequency plasma starts arcing, the diffusion pump unit is pre-evacuated to 1.0×Pa to prevent tungsten and oxygen from reacting to form tungsten oxide. The main process parameters of RF plasma are: argon is used as working gas, side gas and carrier gas, working gas flow rate is 30 slpm, side gas flow rate is 100 slpm, system negative pressure is 200 mm Hg, carrier gas flow rate is 4 slpm, powder feeding rate is 10 g / min, the equipment output power is 45KW. After the obtained precursor powder is sent into the plasma high-temperature zone, the precursor powder absorbs heat, melts and spheroidizes, and is quenched and...

Embodiment example 2

[0029] 1. Preparation of precursor powder

[0030] Using conventional tungsten powder as raw material, granulate with 5wt.% polyvinyl alcohol (PVA) solution, the addition amount is 4wt.%, vacuum dry at 60°C for 1 hour after granulation, and sieve to obtain precursor powder.

[0031] 2. Preparation of ultra-coarse spherical tungsten powder

[0032] Before the radio frequency plasma starts arcing, the diffusion pump unit is pre-evacuated to 1.0×Pa to prevent tungsten and oxygen from reacting to form tungsten oxide. The main process parameters of RF plasma are: argon is used as working gas, side gas and carrier gas, working gas flow rate is 35 slpm, side gas flow rate is 120 slpm, system negative pressure is 240 mm Hg, carrier gas flow rate is 5 slpm, powder feeding rate is 30 g / min, the output power of the equipment is 60KW. After the obtained precursor powder is sent into the plasma high-temperature zone, the precursor powder absorbs heat, melts and spheroidizes, and is quen...

Embodiment example 3

[0034] 1. Preparation of precursor powder

[0035] Using conventional tungsten powder as raw material, granulate with 5wt.% polyvinyl alcohol (PVA) solution, the addition amount is 4wt.%, vacuum dry at 60°C for 1 hour after granulation, and sieve to obtain precursor powder.

[0036] 2. Preparation of ultra-coarse spherical tungsten powder

[0037] Before the radio frequency plasma starts arcing, the diffusion pump unit is pre-evacuated to 1.0×Pa to prevent tungsten and oxygen from reacting to form tungsten oxide. The main process parameters of RF plasma are: argon is used as working gas, side gas and carrier gas, working gas flow rate is 30 slpm, side gas flow rate is 100 slpm, system negative pressure is 220 mm Hg, carrier gas flow rate is 4 slpm, powder feeding rate is 20 g / min, the equipment output power is 50KW. After the obtained precursor powder is sent into the plasma high-temperature zone, the precursor powder absorbs heat, melts and spheroidizes, and is quenched an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com