Preparation method of high-adsorbability graphene aerogel

A graphene airgel, high adsorption technology, applied in the direction of graphene, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of not highlighting the advantages of graphene, achieve faster reduction speed, simple preparation method, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

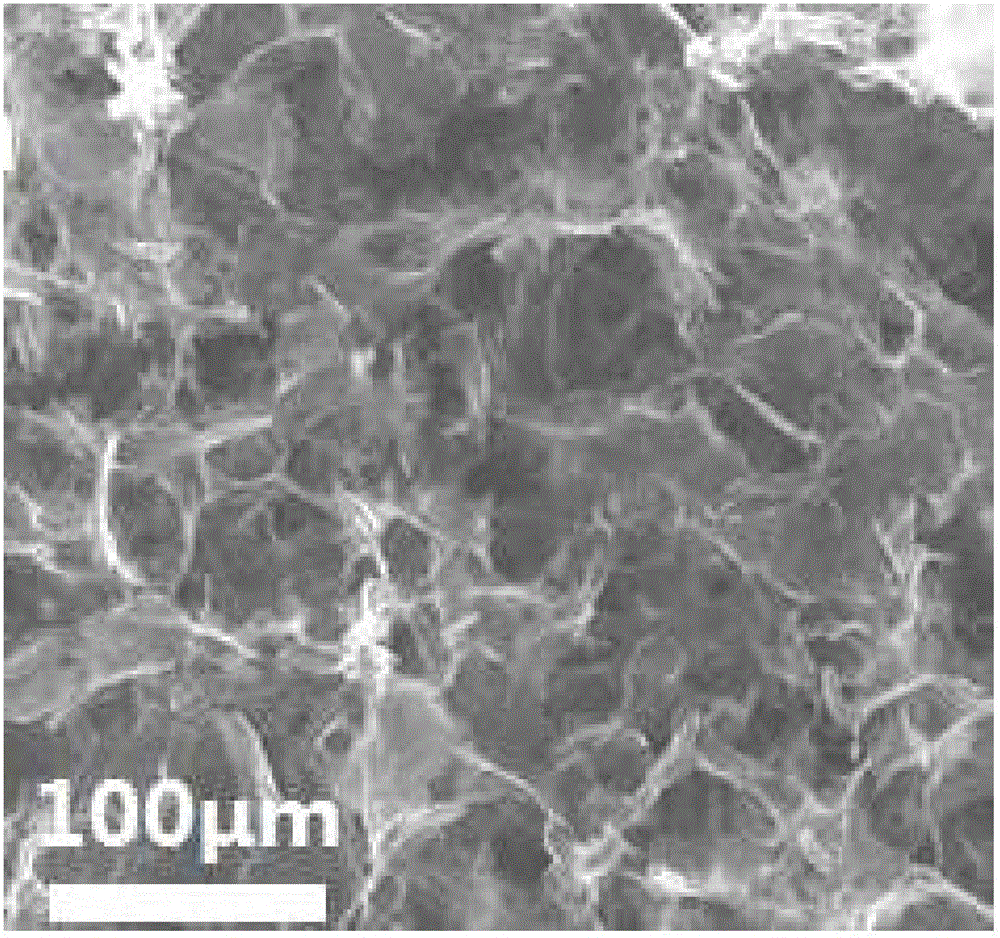

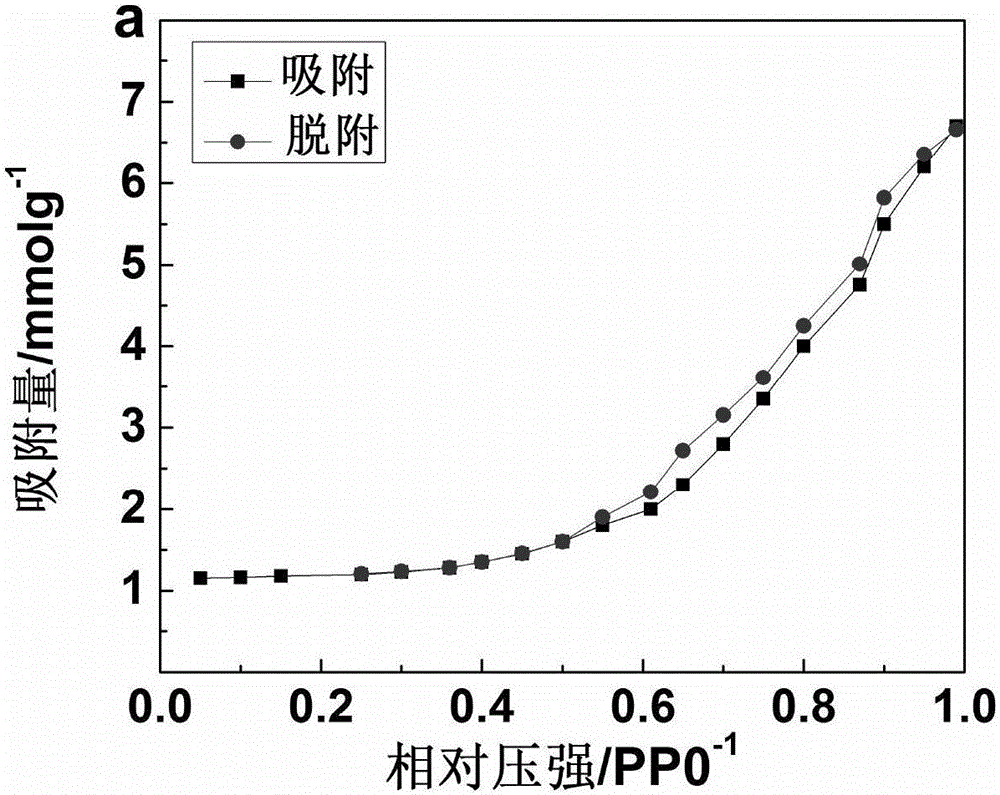

[0024] Weigh 16 mg of solid graphene oxide and place it in 8 mL of deionized water, ultrasonically for 1 h to prepare an aqueous solution of graphene oxide, transfer the aqueous solution into a 20 mL cylindrical glass bottle, mix with 0.3 mg / mL ammonia borane solution and 0.2 mmol / mL ferrous sulfate solution was mixed at a volume ratio of 8:1:1 and mechanically stirred for 20min to obtain a mixed solution. The cylindrical glass bottle was reacted at 95°C for 8h to obtain a cylindrical product; the cylindrical product was soaked in In deionized water for 48 hours, the cylindrical product was pre-frozen at -4°C; the pre-frozen material was placed in a freeze dryer and freeze-dried at -80°C for 48 hours to obtain graphene aerogels , the SEM image of graphene aerogel is shown in figure 1 The nitrogen adsorption curve of the aerogel is shown in figure 2 As shown, the graphene sheets in the aerogel are stacked on each other to form a porous structure and facilitate its application...

Embodiment 2

[0026] Weigh 30mg of solid graphene oxide and place it in 15mL of deionized water, ultrasonicate for 1h to make an aqueous solution of graphene oxide, transfer the aqueous solution into a 50mL cylindrical glass bottle, mix with 0.5mg / mL ammonia borane solution and 0.5 mmol / mL ferrous sulfate solution was mixed at a volume ratio of 10:1:1, ultrasonically dispersed for 15 min to obtain a mixed solution, and the cylindrical glass bottle was reacted at 120 °C for 6 h to obtain a cylindrical product; the cylindrical product was soaked in In deionized water for 24 hours, the cylindrical product was pre-frozen at -4°C; the pre-frozen material was placed in a freeze dryer and freeze-dried at -80°C for 24 hours to obtain graphene aerogels .

Embodiment 3

[0028] Weigh 30mg of solid graphene oxide and place it in 10mL of deionized water, ultrasonicate for 1h to prepare an aqueous solution of graphene oxide, transfer the aqueous solution into a 50mL cylindrical glass bottle, mix with 0.3mg / mL ammonia borane solution and 0.5 mmol / mL of ferrous sulfate solution was mixed at a volume ratio of 8:1:1, and mechanically stirred for 25 minutes to obtain a mixed solution. The cylindrical glass bottle was reacted at 105 °C for 7 hours to obtain a cylindrical product; the cylindrical product was soaked In deionized water for 24h, the cylindrical product was pre-frozen at -4°C; the pre-frozen material was placed in a freeze dryer, and freeze-dried at -80°C for 72h to obtain graphene gas condensate. glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com