A kind of preparation of alumina/carbon nanocomposite material using alkali residue wastewater and aluminum-containing waste acid

A composite material and alkali slag wastewater technology, which is applied in the fields of aluminum hydroxide preparation, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of high cost, untreated acid radicals, difficulty in industrialization, etc., and achieve good adsorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

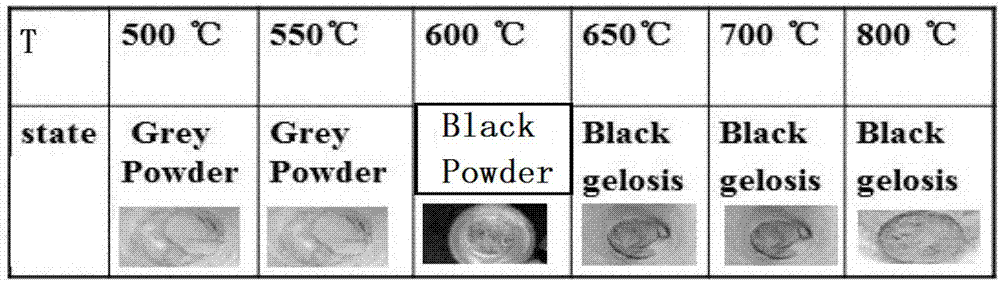

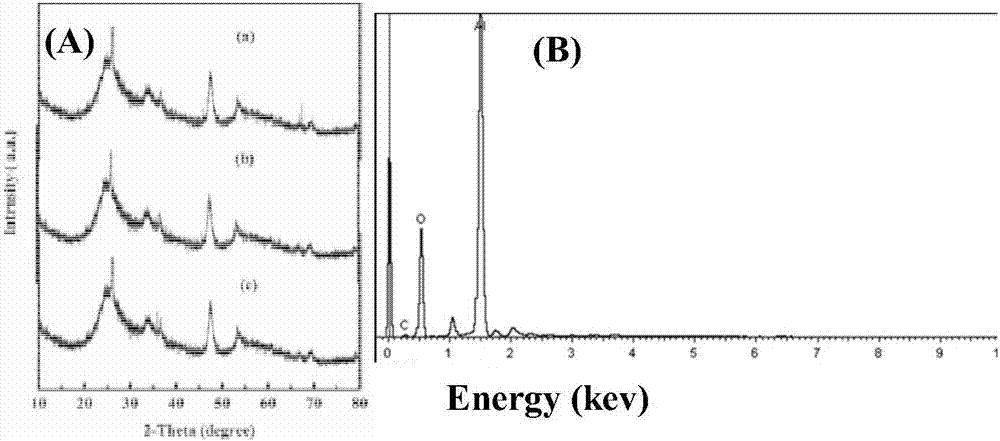

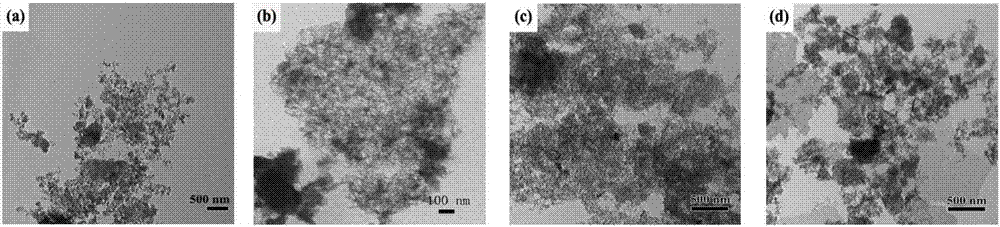

[0020] Embodiment 1. A method for preparing alumina / carbon nanocomposites by using alkali slag wastewater and aluminum-containing waste acid, the method comprises the following steps: (1) Take a certain amount of alkali slag wastewater, filter it with a filter screen, remove For solid impurities, the measured pH value is 13-14; gradually add aluminum-containing waste acid solution to the alkali slag wastewater until precipitation occurs, and when the pH value of the obtained solid-liquid mixture is 6-8, use it for later use; (2) Dry the solid-liquid mixture obtained in step (1) at 60-100°C for more than 24 hours to obtain a dried composite material precursor, take it out and grind it for later use; (3) dry the composite material precursor obtained in step (2) The body is calcined at 400-800°C for 2-4h in a nitrogen or argon atmosphere, the heating rate is 5-15°C / min, and the composite material can be obtained after cooling to room temperature. The obtained composite material i...

Embodiment 2

[0022] Embodiment 2, the method for preparing alumina / carbon nanocomposites by using alkali slag waste water and aluminum-containing waste acid, comprises the following steps

[0023] (1) Take 150ml of alkali slag wastewater from the oil refinery of Dushanzi Petrochemical Plant and filter it with a filter. As for the conical flask, the pH range is about 13-14. Take another 50-100ml of aluminum-containing waste acid solution, add the aluminum-containing waste acid solution drop by drop, shake the Erlenmeyer flask while adding dropwise, until precipitation occurs and does not dissolve within 5 seconds, and the pH value of the solution is about 6-8;

[0024] (2) Dry the solid-liquid mixture obtained in step (1) at 60-100°C for more than 24 hours to obtain a dried composite material precursor. The appearance color of the sample is earthy yellow. After taking it out, use a pulverizer to crush it to 100 mesh Left and right, the appearance color of the sample is khaki;

[0025] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com