Preparing method and application of orthorhombic phase cesium-lead iodide monocrystal nanowire

A technology of single crystal nanometer and lead iodide, which is applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve problems such as unfavorable full-band light-emitting and display devices, unfavorable industrial scale production, and short product length. Achieve excellent X-ray fluorescence characteristics, facilitate industrial scale production, and have simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

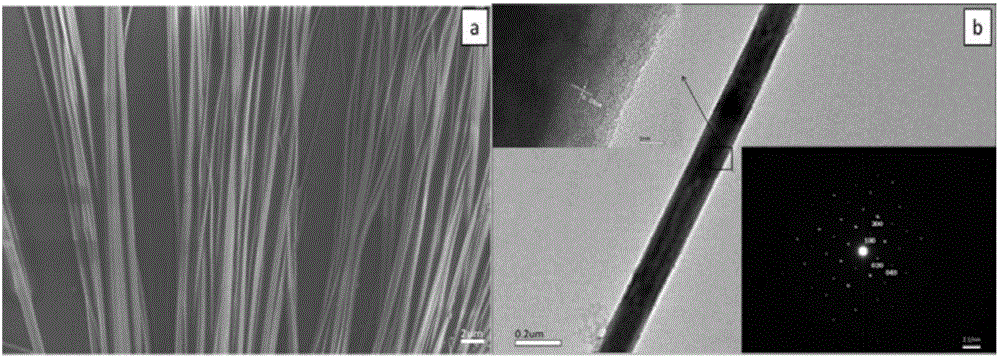

[0036] The concrete steps of preparation are:

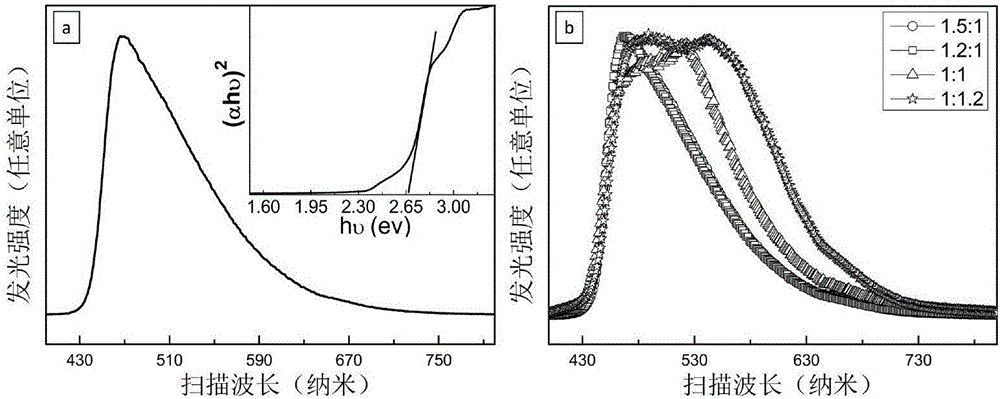

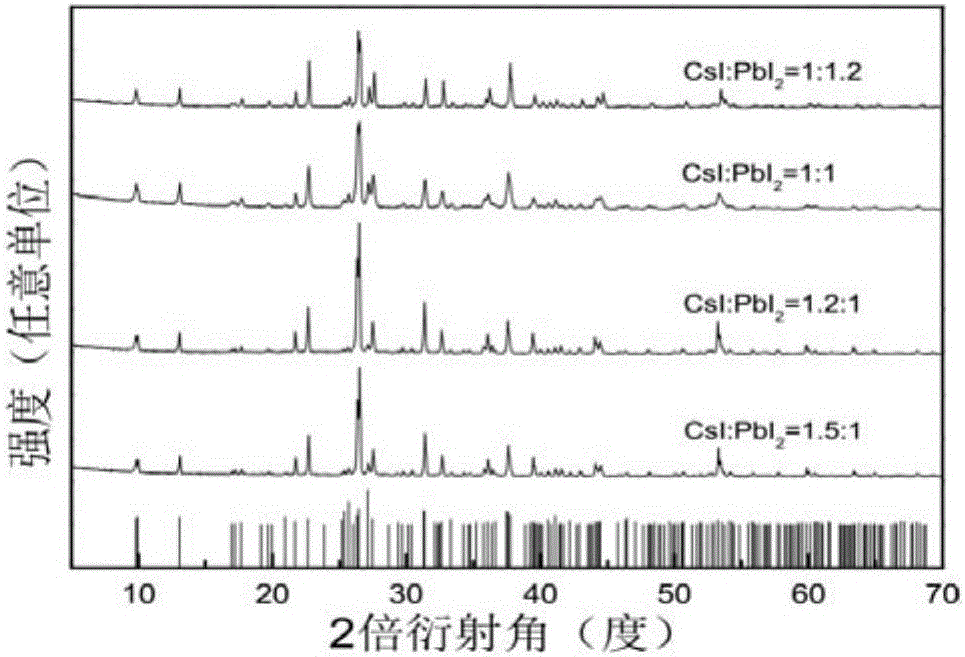

[0037] Step 1, first place γ-butyrolactone in a protective atmosphere, stir at 68.5°C for 15 minutes, then add lead iodide in the ratio of 11:2 by weight to γ-butyrolactone In protective atmosphere, γ-butyrolactone under stirring at 72.5°C, brick red turbid liquid is obtained; wherein, the protective atmosphere is nitrogen atmosphere. Then cesium iodide was added to the brick-red turbid liquid to obtain a mixed solution; wherein, the weight ratio of cesium iodide to lead iodide in the brick-red turbid liquid was 1:1.2.

[0038]In step 2, the mixed solution is continuously placed in a protective atmosphere at 68.5° C. and stirred for 100 minutes to obtain a bright yellow mixed solution; wherein the protective atmosphere is a nitrogen atmosphere. After the bright yellow mixed solution is cooled under a protective atmosphere, it is evaporated to dryness at 68.5° C. with a relative humidity of 1%. Wherein, the protective atmosphere ...

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1, first place γ-butyrolactone in a protective atmosphere, stir at 69.5°C for 15 minutes, then add lead iodide in the ratio of 12:2 by weight to γ-butyrolactone In protective atmosphere, γ-butyrolactone under stirring at 71.5°C, a brick-red turbid liquid was obtained; wherein, the protective atmosphere was a nitrogen atmosphere. Then cesium iodide was added to the brick-red turbid liquid to obtain a mixed solution; wherein, the weight ratio of cesium iodide to lead iodide in the brick-red turbid liquid was 1.1:1.1.

[0042] In step 2, the mixed solution was continuously placed in a protective atmosphere at 69.5° C. and stirred for 95 minutes to obtain a bright yellow mixed solution; wherein the protective atmosphere was a nitrogen atmosphere. After the bright yellow mixed solution is cooled under a protective atmosphere, it is evaporated to dryness at 69.5° C. with a relative humidity of 5%. Wherein, the protective a...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] Step 1, first place γ-butyrolactone in a protective atmosphere, stir at 70.5°C for 15 minutes, then add lead iodide in the ratio of 13:2 by weight of lead iodide and γ-butyrolactone In protective atmosphere, γ-butyrolactone under stirring at 70.5°C, brick red turbid liquid is obtained; wherein, the protective atmosphere is nitrogen atmosphere. Then cesium iodide was added to the brick-red turbid liquid to obtain a mixed solution; wherein, the weight ratio of cesium iodide to lead iodide in the brick-red turbid liquid was 1.2:1.15.

[0046] In step 2, the mixed solution is continuously placed in a protective atmosphere at 70.5° C. and stirred for 90 minutes to obtain a bright yellow mixed solution; wherein the protective atmosphere is a nitrogen atmosphere. After the bright yellow mixed solution is cooled under a protective atmosphere, it is evaporated to dryness at 70.5° C. with a relative humidity of 10%; wherein, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com