Method for improving frost resistance of excess-sulfate phosphogypsum slag cement product

A technology of slag cement and phosphogypsum, which is applied in the field of building materials, can solve the problems that cement concrete products cannot be applied, is unfavorable for wide-scale promotion, and has high additive dosage, achieves important economic and environmental benefits, is beneficial to environmental protection, and has a simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0025] A method for improving the antifreeze performance of phosphogypsum slag cement products, comprising the following steps:

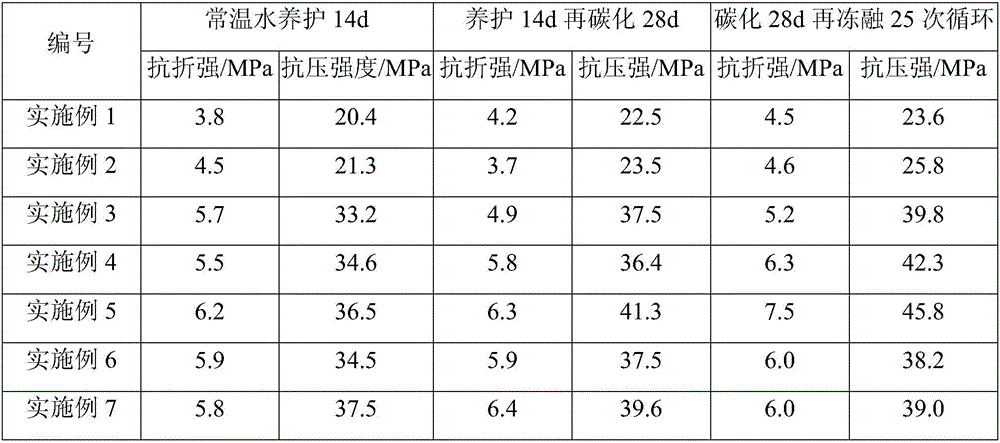

[0026] 1) Preparation of persulfophosphogypsum slag cement products: After mixing phosphogypsum, slag powder, and cement clinker powder (P.O 42.5 cement) according to the proportioning conditions described in Table 1, add standard sand, and then press "cement mortar "Strength Test Method" (ISO method) (GB / T17671-1999) to form a persulfur gypsum slag cement mortar test block;

[0027] 2) Carbonization curing: the obtained phosphogypsum slag cement mortar test block was maintained in the air for 3 days, then placed in normal temperature water for 14 days, and then placed in an air atmosphere with a volume concentration of carbon dioxide of 20% for 28 days. After another 25 freeze-thaw cycles, the strength of the samples at each stage was tested, and the results are shown in Table 2.

[0028] Table 1 Formula of persulfur gypsum slag cement products

...

Embodiment 8~10

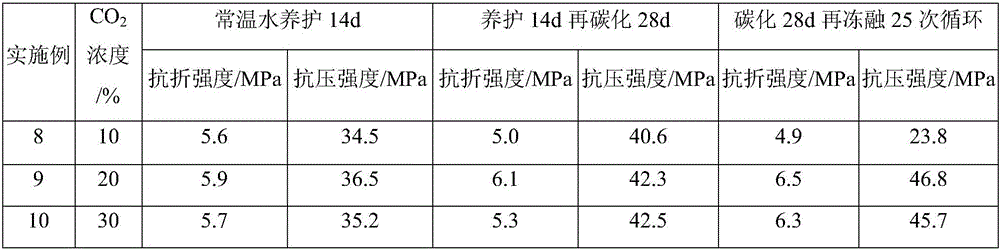

[0034] A method for improving the antifreeze performance of phosphogypsum slag cement products, comprising the following steps:

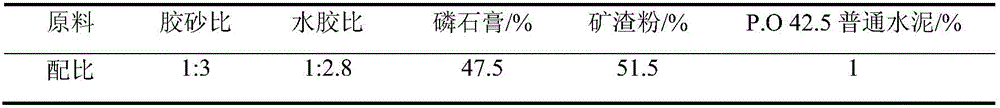

[0035] 1) Preparation of persulfur gypsum slag cement products: After mixing phosphogypsum, slag powder, and cement clinker powder (P.O 42.5 cement) according to the ratio described in Table 3, add standard sand (mortar ratio is 1:3), Then according to the "Cement Mortar Strength Test Method" (ISO method) (GB / T 17671-1999) type, the persulfur gypsum slag cement mortar test block is obtained;

[0036] 2) Carbonization curing: the obtained phosphogypsum slag cement mortar test block was cured in the air for 3 days, then placed in normal temperature water for 14 days, and then placed in a carbon dioxide volume concentration of 10-30% (see Table 4). Continue curing in the air atmosphere for 28 days, and then go through 25 freeze-thaw cycles to test the strength of the samples at each stage.

[0037] Table 3 Formula of persulfur gypsum slag cement produ...

Embodiment 11~13

[0043] A method for improving the antifreeze performance of phosphogypsum slag cement products, comprising the following steps:

[0044] 1) Preparation of persulfur gypsum slag cement products: After mixing phosphogypsum, slag powder, and cement clinker powder (P.O 42.5 cement) according to the proportioning conditions described in Table 3, add standard sand, and then press "cement mortar "Strength Test Method" (ISO method) (GB / T17671-1999) to form a persulfur gypsum slag cement mortar test block;

[0045] 2) Carbonization curing: the obtained phosphogypsum slag cement mortar test block was cured in the air for 3 days, then placed in normal temperature water for 3 days, 7 days, and 14 days, and then placed in air with a volume concentration of carbon dioxide of 20%. Continue curing in the atmosphere for 28 days, and then go through 25 freeze-thaw cycles to test the strength of the samples at each stage. The results are shown in Table 5.

[0046] It can be seen from Table 5 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com