Multifunctional biological organic slow-release fertilizer and preparation method thereof

A slow-release fertilizer and multi-functional technology, which is applied in the field of multi-functional bio-organic slow-release fertilizer and its preparation, can solve problems such as limiting the multi-functionality of bio-organic fertilizer, improve crop quality and yield, inhibit diseases and insect pests, and improve absorption and utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

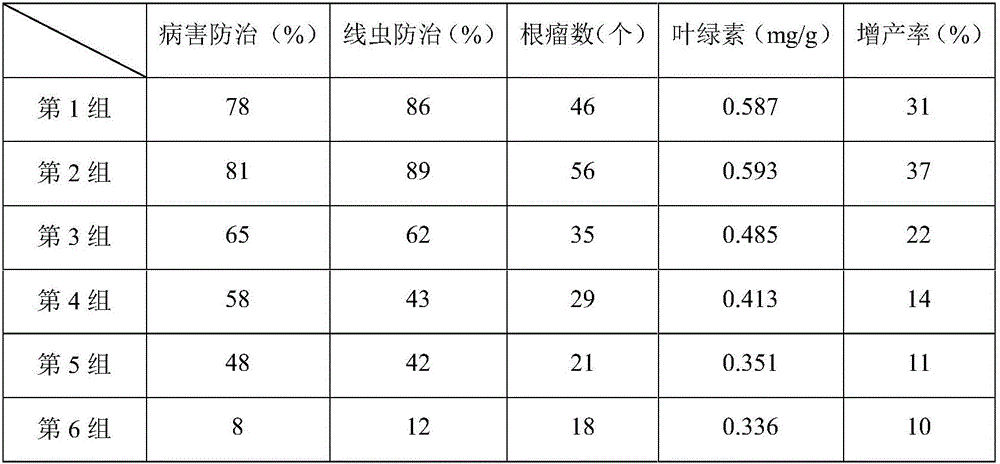

Embodiment 1

[0029] The preparation of embodiment 1 multifunctional bio-organic slow-release fertilizer A

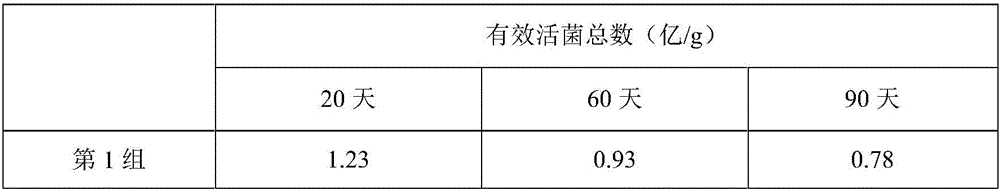

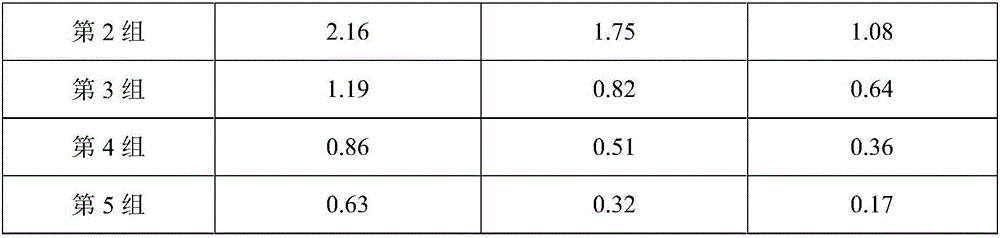

[0030] With 3.0kg amino acid powder, 35.0kg yeast powder, 31.0kg humic acid, 7.0kg waste molasses and 1.0kg composite microorganism (0.4kg subtilis bacillus, 0.2kg amyloliquefaciens bacillus and 0.4kg jelly-like bacillus) with nitrogen Phosphorus and potassium nutrient raw materials are processed and fully mixed evenly, then granulated and dried, and the water content is controlled at 10±0.2%, so as to obtain a bio-organic masterbatch with 7.0% nitrogen, phosphorus and potassium nutrients and effective viable bacteria count ≥ 0.5 billion / g;

[0031] Mix 2.4kg chitosan, 7.2kg humic acid powder and 2.4kg shell powder and then fully grind with 2kg cyclodextrin and 2kg water to make a uniform paste; mix 2kg carboxymethyl cellulose with 2kg water To form a non-layered transparent liquid, slowly add carboxymethyl cellulose solution to the paste while stirring, and stir well to form an emul...

Embodiment 2

[0033] The preparation of embodiment 2 multifunctional bio-organic slow-release fertilizer B

[0034] With 5.0kg amino acid powder, 40.0kg yeast powder, 45.0kg humic acid, 10.0kg waste molasses and 1.8kg composite microorganism (0.6kg subtilis bacillus, 0.6kg amyloliquefaciens bacillus and 0.6kg jelly-like bacillus) with nitrogen Phosphorus and potassium nutrient raw materials are processed and fully mixed in proportion, then granulated and dried, and the water content is controlled at 10±0.2%, so as to obtain a bio-organic masterbatch with 8.0% nitrogen, phosphorus and potassium nutrients and effective viable bacteria count ≥ 100 million / g;

[0035] Mix 3kg chitosan, 9kg humic acid powder and 3kg shell powder evenly, then fully grind them with 3kg cyclodextrin and 2kg water to make a uniform paste; layer of transparent liquid, slowly add carboxymethyl cellulose solution into the paste while stirring, and stir well to form an emulsion with certain fluidity; add the above emuls...

Embodiment 3

[0037] The preparation of embodiment 3 bio-organic slow-release fertilizer A1

[0038] Prepare bio-organic slow-release fertilizer according to the method of embodiment 1, wherein according to the following requirements, adjust the consumption of related substances and substances thereof, compared with embodiment 1, the inner layer microorganism is 1.0kg Paecilomyces lilacinus in embodiment 3, The microorganisms in the outer layer were 0.4kg Bacillus subtilis, 0.2kg Bacillus amyloliquefaciens and 0.4kg Bacillus jelly-like, and other processes were the same as in Example 1 to obtain bio-organic slow-release fertilizer A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com