Preparation method of globefish skin gelatin

A technology of fish skin gelatin and puffer fish skin, which is applied in the field of preparation of puffer fish skin gelatin, can solve the problems of long cycle and high energy consumption, and achieve the effect of low cost, low concentration and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

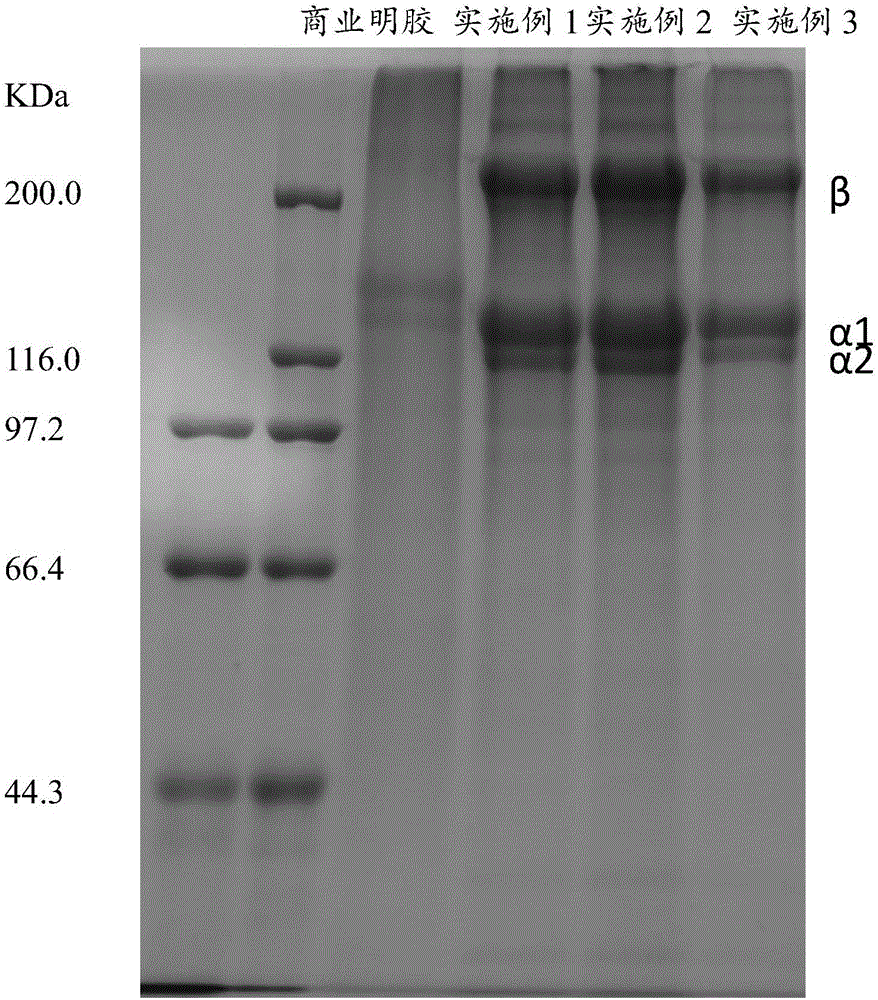

Examples

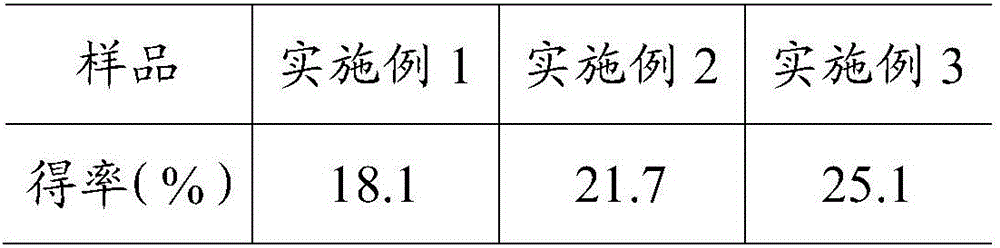

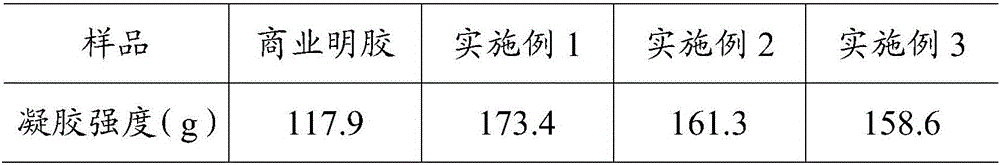

Embodiment 1

[0031] The method for preparing puffer fish skin gelatin comprises the following steps:

[0032] (1) Wash the puffer fish skin, remove impurities such as sediment, and chop;

[0033] (2) Soak the cleaned fish skin with a solution containing 0.1mol / L sodium hydroxide and 1% hydrogen peroxide, wherein the mass volume ratio of the fish skin to the solution is 1g:8ml, and the soaking time is 6 hours in total, every 3 hours Change the solution once, the ambient temperature is 4°C;

[0034] (3) The fish skin obtained in step (2) is repeatedly washed with clear water to make the pH reach 7;

[0035] (4) Soak the fish skin obtained in step (3) with an aqueous solution with a concentration of detergent of 1 wt%, wherein the mass volume ratio of the fish skin to the solution is 1:10, the soaking time is 12h, and the ambient temperature is 4°C ;

[0036] (5) the fish skin obtained in step (4) is extracted with 0.5mol / L acetic acid solution at 25°C under constant magnetic stirring, whe...

Embodiment 2

[0043] The method for preparing puffer fish skin gelatin comprises the following steps:

[0044] (1) Wash the puffer fish skin, remove impurities such as sediment, and chop;

[0045] (2) Soak the washed fish skin with a solution containing 0.2mol / L sodium hydroxide and 2% hydrogen peroxide, wherein the mass volume ratio of the fish skin to the solution is 1:10, and the soaking time is 5 hours in total, every 2.5 h Change the solution once, and the ambient temperature is 4°C;

[0046] (3) The fish skin obtained in step (2) is repeatedly washed with clear water to make the pH reach 7;

[0047](4) Soak the fish skin obtained in step (3) with an aqueous solution with a detergent concentration of 2wt%, wherein the mass volume ratio of the fish skin to the solution is 1:12, the soaking time is 8h, and the ambient temperature is 4°C ;

[0048] (5) The fish skin obtained in step (4) is extracted with 0.09mol / L acetic acid solution at 35° C. under constant magnetic stirring, wherein...

Embodiment 3

[0055] The method for preparing puffer fish skin gelatin comprises the following steps:

[0056] (1) Wash the puffer fish skin, remove impurities such as sediment, and chop;

[0057] (2) soak the cleaned fish skin with a solution containing 0.1mol / L sodium hydroxide and 0.8% hydrogen peroxide, wherein the mass volume ratio of the fish skin to the solution is 1g:5ml, and the soaking time is 9 hours in total, every 4.5 h Change the solution once, and the ambient temperature is 4°C;

[0058] (3) The fish skin obtained in step (2) is repeatedly washed with clear water to make the pH reach 7;

[0059] (4) Soak the fish skin obtained in step (3) with an aqueous solution with a detergent concentration of 2wt%, wherein the mass volume ratio of the fish skin to the solution is 1:7, the soaking time is 9h, and the ambient temperature is 4°C ;

[0060] (5) extract the fish skin obtained in step (4) with 0.02mol / L acetic acid solution at 45°C with constant magnetic stirring, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com