Phosphorus-doped fluorescent carbon dots with high fluorescence quantum yield and preparation method and application thereof

A fluorescence quantum yield, fluorescent carbon dot technology, applied in fluorescence/phosphorescence, chemical instruments and methods, nano-optics, etc., can solve the problems of low fluorescence quantum yield, complex preparation process, etc., and achieve good biocompatibility, Simple preparation method and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.2g of tannic acid and 0.2g of PEI, add 10ml of deionized water, then add 0.5ml of phosphoric acid, fully stir and dissolve, transfer to a 50ml reaction kettle, put into a blast drying oven, and dry at 140 After heating at ℃ for 2h, cooling to room temperature naturally, a dark brown carbon dot solution was obtained, and then after dialysis and freeze-drying, phosphorous-doped fluorescent carbon dots (CDs) solid powder was finally obtained. The fluorescence quantum yield is 25.4%.

[0030] Transmission electron micrographs of phosphorus-doped fluorescent carbon dots figure 1 shown. It can be seen from the figure that the particle size of carbon dots is about 9nm.

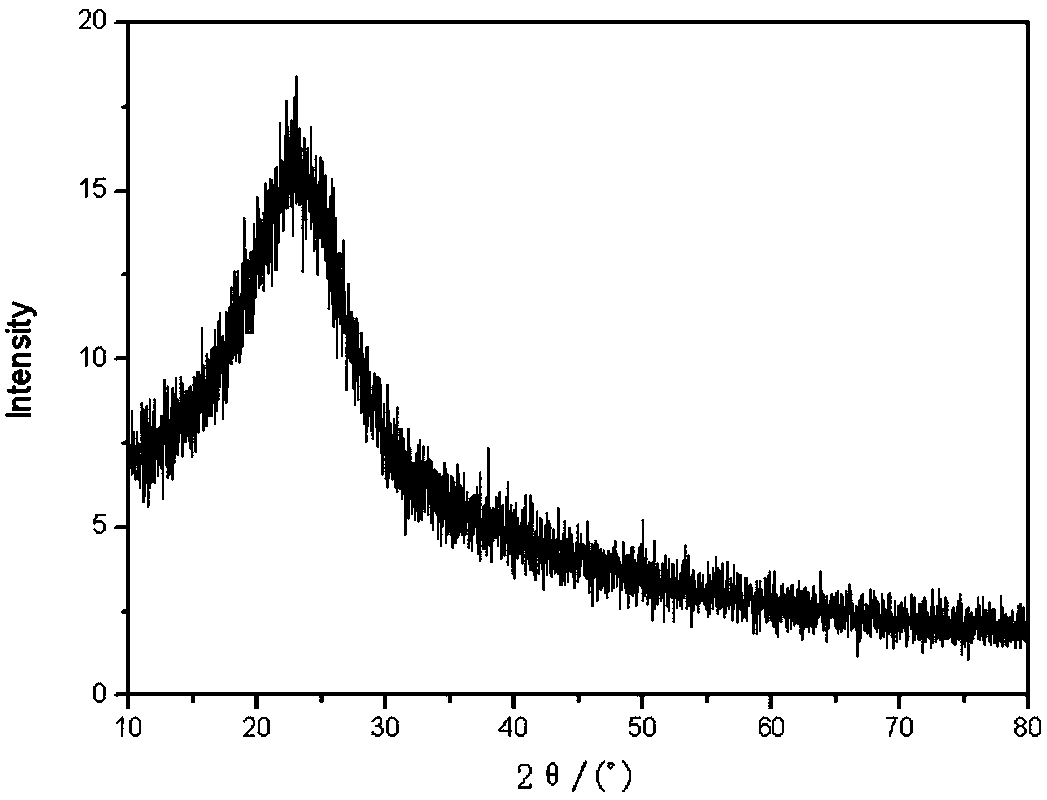

[0031] The X-ray diffraction spectrum of phosphorus-doped fluorescent carbon dots is as follows: figure 2 shown. X-ray diffraction analysis shows that the carbon dot powder has an obvious and broad diffraction peak around 2θ=23°, indicating that the carbon dots exist in an amorphous form.

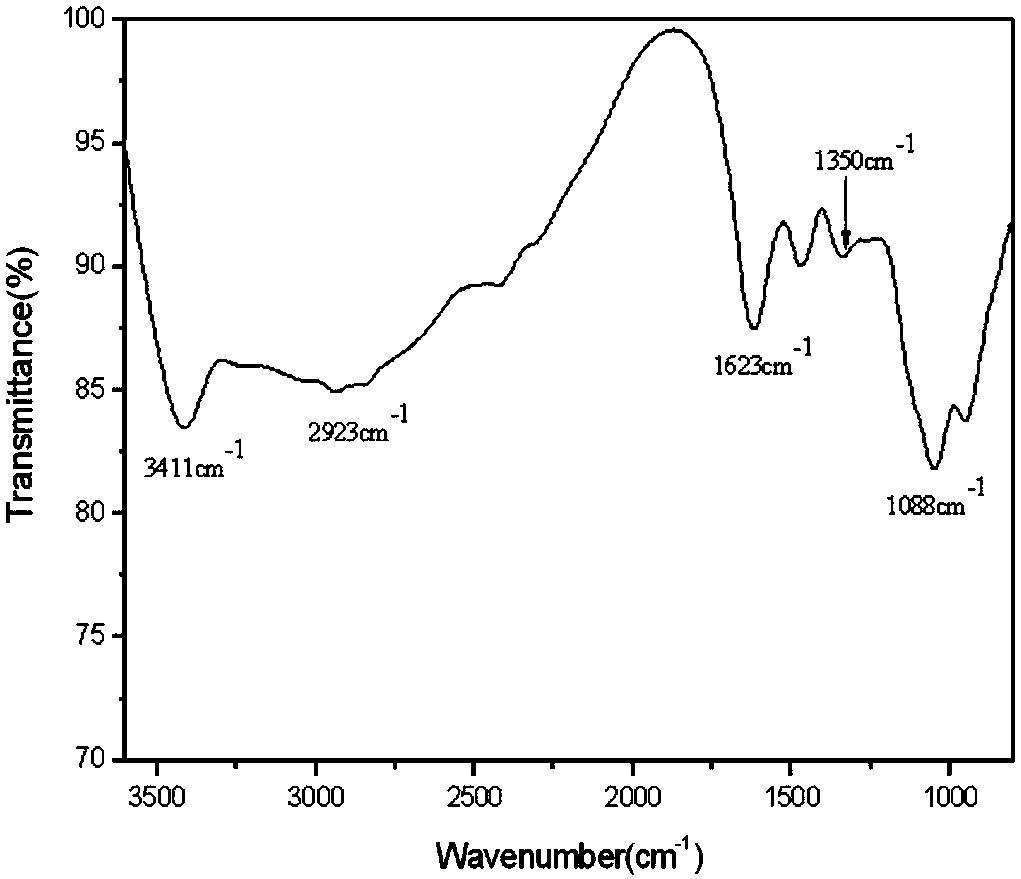

[0032...

Embodiment 2

[0041] Weigh 0.2g of tannic acid and 1.0g of PEI, add 15ml of deionized water, then add 1.0ml of phosphoric acid, fully stir and dissolve, transfer to a 50ml reaction kettle, put into a blast drying oven, and dry at 180 ℃ for 4 hours, and naturally cooled to room temperature to obtain a dark brown carbon dot solution, which was then dialyzed to obtain a phosphorus-doped fluorescent carbon dot solution.

Embodiment 3

[0043] Weigh 0.5g of tannic acid and 1.2g of PEI, add 20ml of deionized water, add 1.5ml of phosphoric acid, fully stir to dissolve, transfer to a 50ml reaction kettle, put it in a blast drying oven, and dry it at 200°C Heating for 4 hours, cooling down to room temperature naturally to obtain a dark brown carbon dot solution, and then dialysis to finally obtain a phosphorus-doped fluorescent carbon dot solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com