A Method of Controlling Grain Equiaxation to Improve the Plasticity of Ti20zr6.5al4v Alloy

A ti20zr6.5al4v, alloy technology, applied in the field of materials, can solve the problems of only 2.05% elongation, plasticity needs to be improved urgently, and the effect is not obvious, so as to achieve the effect of easy operation, low processing cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

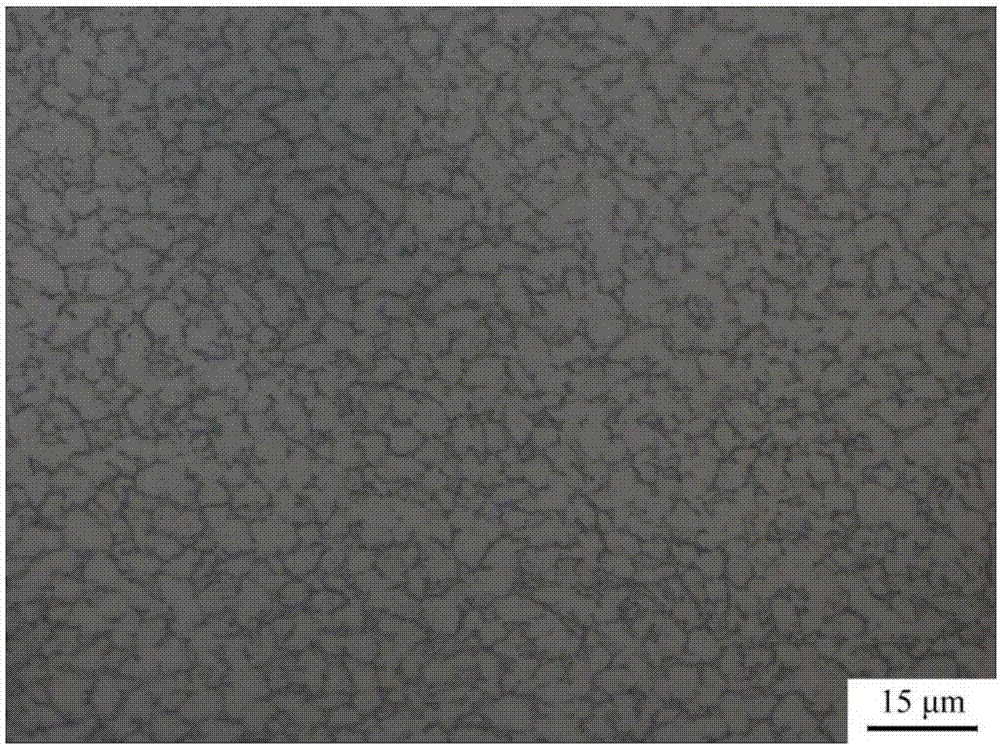

Embodiment 1

[0025] Take the Ti20Zr6.5Al4V alloy bar, the mass percentage of its chemical composition is Ti: 67.1%, Zr: 18.8%, Al: 5.6%, V: 3.8%, and cut the alloy bar into Φ42×16mm round ingots with a wire cutting machine And clean up, the alloy ingot is put into the vacuum tube type electric resistance furnace heat (treatment furnace model: QSH-VTF-1200T; Manufacturer: Shanghai Quanshuo Electric Furnace Co., Ltd., the following examples are the same) to heat, using argon as the protective atmosphere, When the temperature rises to 970°C, keep it warm for 30 minutes, take out the alloy ingot and quickly put it in water for quenching; before rolling, use a box-type resistance furnace (model: KL-13; manufacturer: Tianjin Kaiheng Electric Heating Technology Co., Ltd., the following The embodiment is the same) the temperature is raised to 800°C at a heating rate of 10°C / min, and after holding the heat for 2min, the alloy ingot is rolled and deformed with a twin-roll mill at a rolling speed of 0...

Embodiment 2

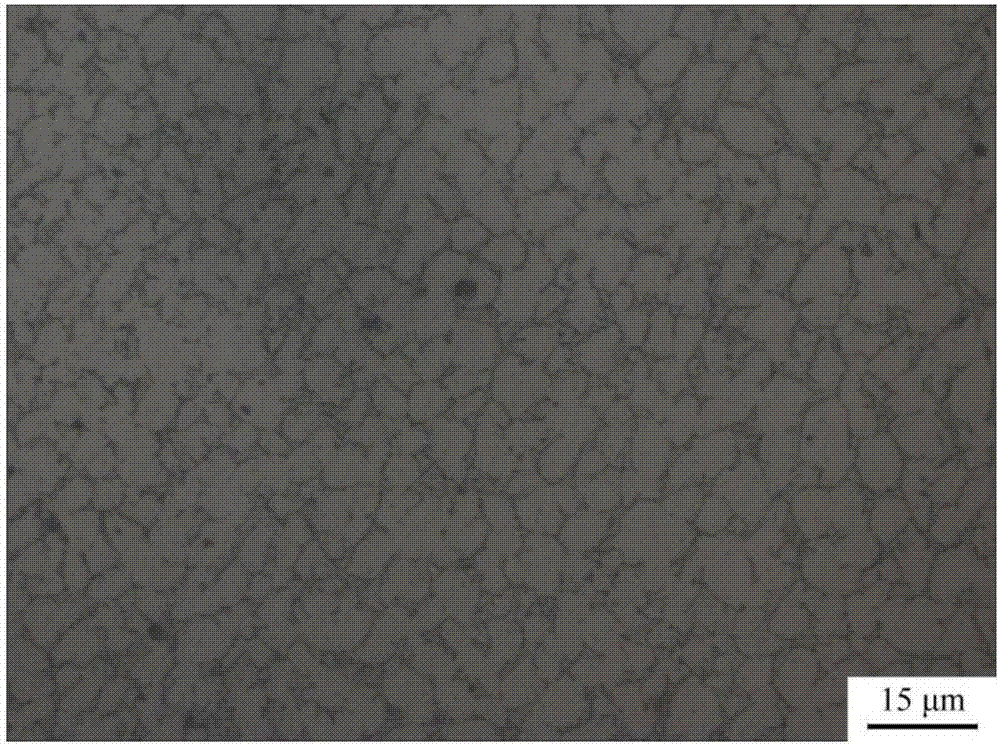

[0027] Take the Ti20Zr6.5Al4V alloy bar, the mass percentage of its chemical composition is Ti: 67.1%, Zr: 18.8%, Al: 5.6%, V: 3.8%, and cut the alloy bar into Φ42×16mm round ingots with a wire cutting machine And clean it up, heat the alloy ingot in a vacuum tube resistance furnace, use argon as a protective atmosphere, when the temperature rises to 970 ° C, keep it warm for 30 minutes, take out the alloy ingot and quickly put it in water for quenching; before rolling, use The box-type resistance furnace raised the temperature to 850°C at a heating rate of 10°C / min. After holding the temperature for 4 minutes, the alloy ingot was rolled and deformed with a two-roll rolling mill. The rolling speed was 0.4m / s, and the single-pass pressing The amount is 1.5mm; after each pass of rolling, put the alloy into the heat treatment furnace for reheating, when the temperature rises to 850°C, keep it warm for 4 minutes and then roll again, repeat heating-rolling 7 times in this way until ...

Embodiment 3

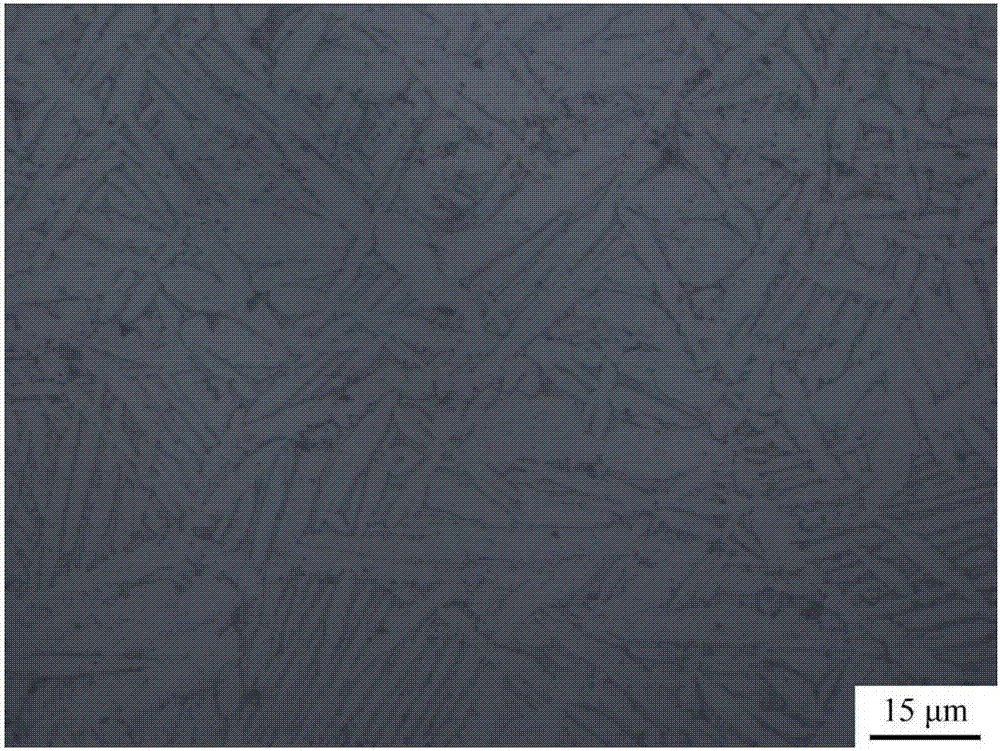

[0029] Take the Ti20Zr6.5Al4V alloy bar, the mass percentage of its chemical composition is Ti: 66.5%, Zr: 18.7%, Al: 6.0%, V: 3.9%, and cut the alloy bar into Φ42×16mm round ingots with a wire cutting machine And clean it up, heat the alloy ingot in a vacuum tube resistance furnace, use argon as a protective atmosphere, when the temperature rises to 1050 ° C, keep it warm for 20 minutes, take out the alloy ingot and quickly put it in water for quenching; before rolling, use The box-type resistance furnace raises the temperature to 900°C at a heating rate of 10°C / min. After holding the temperature for 1min, the alloy ingot is rolled and deformed with a two-roll rolling mill at a rolling speed of 0.6m / s, and single-pass pressing The amount is 2mm; after each pass of rolling, put the alloy into the heat treatment furnace for reheating, when the temperature rises to 900°C, keep it warm for 1min and then roll again, repeat heating-rolling 5 times until the thickness of the alloy is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com