Multistage composite metal ceramic, preparation method of multistage composite metal ceramic and shield cutter

A composite metal and ceramic technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of short life and low wear resistance of rock drilling tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

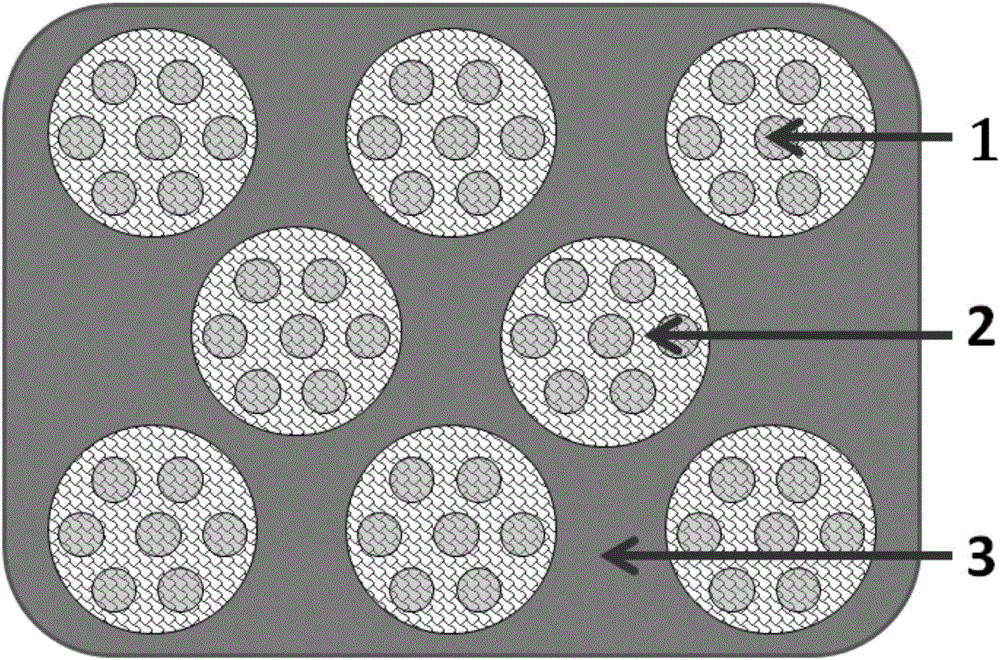

[0050] The present invention also provides a method for preparing a multi-stage composite cermet, comprising the following steps:

[0051] A) n layers of transition phase are coated on the outer layer of the wear-resistant phase to obtain aggregates, n≥1;

[0052] The hardness of the n-layer transition phase gradually decreases, and the transition phase layer contacting the wear-resistant phase has the highest hardness;

[0053] The wear-resistant phase includes AlMgB 14 -Ni 3 Al-SiC alloy;

[0054] B) mixing the pellets with the matrix and sintering to obtain a multi-level composite cermet.

[0055] In the present invention, the outer layer of the spherical powder particles of the wear-resistant phase preferably includes n layers of transition phases to obtain aggregates, n≥1. In the present invention, the outer layer of spherical powder particles of the wear-resistant phase is preferably coated with n layers of transition phases to obtain aggregates, specifically Yes, th...

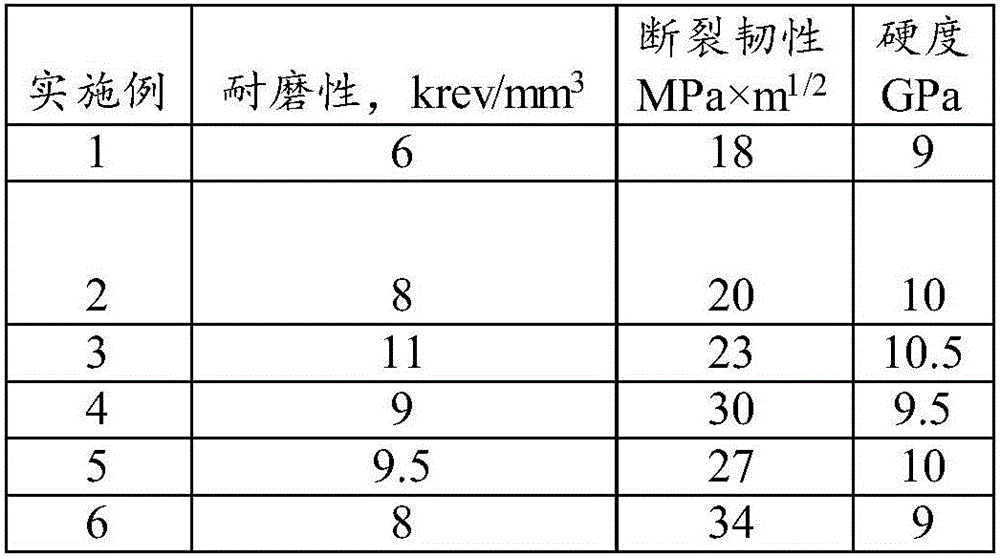

Embodiment 1

[0070] Put boron powder in 1×10 -3 In a Pa vacuum furnace, heat from room temperature to 1500°C and keep it warm for 2 hours, then cool down to room temperature with the furnace; mix aluminum powder, magnesium powder and boron powder in a molar ratio of Al: Mg: B = 1:1:14 to obtain a mixture , and then the mixture was placed under 20MPa and heated to 1450°C and kept for 90min, and AlMgB was obtained after cooling 14 , the AlMgB 14 AlMgB obtained after grinding 14 Pre-reaction powder.

[0071] In terms of mass fraction, 19% of Al, 9.0% of Cr, 0.65% of Zr, 0.6% of Y, 0.6% of V, 1% of B and the rest of Ni are mixed together to obtain a mixed powder; Ball mill the mixed powder for 50 h under an inert atmosphere to obtain Ni 3 Al mixed powder.

[0072] In terms of mass fraction, 2% SiC whiskers, 4% Ni 3 Al and 94% AlMgB 14 The pre-reaction powder is mixed evenly and passed through a 100-mesh sieve, and AlMgB is prepared by adding a forming agent, wet grinding, atomizing and ...

Embodiment 2

[0076] Put boron powder in 1×10 -3 In a Pa vacuum furnace, heat from room temperature to 1500°C and keep it warm for 2 hours, then cool down to room temperature with the furnace; mix aluminum powder, magnesium powder and boron powder in a molar ratio of Al: Mg: B = 1:1:14 to obtain a mixture , and then the mixture was placed under 20MPa and heated to 1450°C and kept for 90min, and AlMgB was obtained after cooling 14 , the AlMgB 14 AlMgB obtained after grinding 14 Pre-reaction powder.

[0077] In terms of mass fraction, 19% of Al, 9.0% of Cr, 0.65% of Zr, 0.6% of Y, 0.6% of V, 1% of B and the rest of Ni are mixed together to obtain a mixed powder; Ball mill the mixed powder for 50 h under an inert atmosphere to obtain Ni 3 Al mixed powder.

[0078] In terms of mass fraction, 4% SiC whiskers, 6% Ni 3 Al and 90% AlMgB 14 The pre-reaction powder is prepared by adding a molding agent and mixing evenly, passing through a 100-mesh sieve, spraying granulation, sieving, dewaxing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com