An electrically adjustable up-conversion luminescent lead-free ferroelectric single crystal and its preparation method

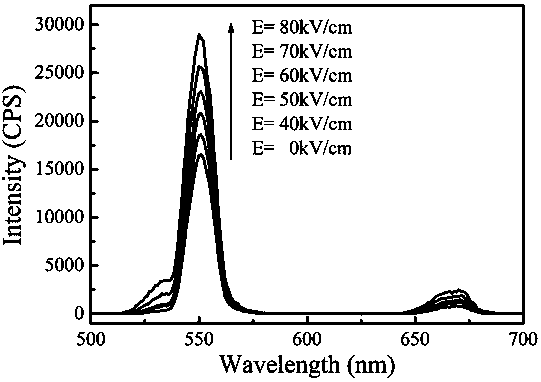

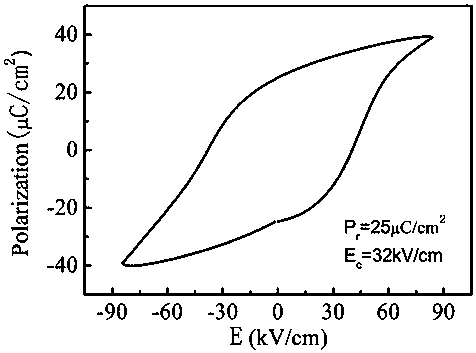

A single crystal and single crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of low luminous intensity and non-adjustable luminous intensity, and achieve high luminous intensity, excellent ferroelectric properties, and high control degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

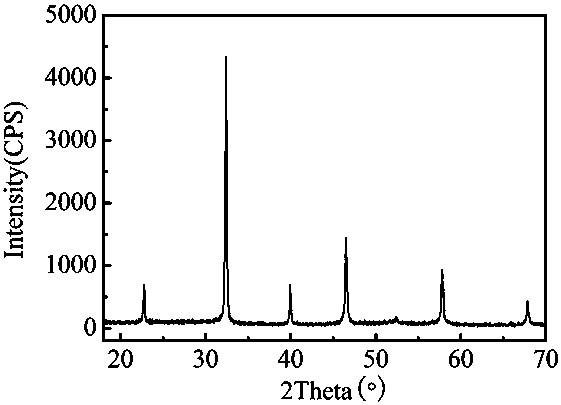

[0024] Na with a purity greater than 99.99% 2 CO 3 、 Bi 2 o 3 、TiO 2 and Er 2 o 3 After the powder is fully dried, according to the general formula (Na 0.5 Bi 0.49 Er 0.01 )TiO 3 ,in x =0.01, accurately weigh the powders of the stoichiometric ratio, and ball mill them for 10 hours to make them evenly mixed; put the mixture in a platinum crucible, and put the platinum crucible into a container filled with Bi 2 o 3 and Na 2 CO 3 Powder in the covered corundum crucible, where Bi 2 o 3 Powder, Na 2 CO 3 The molar ratio of the powder to the mixture in the platinum crucible is 0.2:0.2:1; the corundum crucible is placed in a muffle furnace, and a solid phase reaction is carried out at a temperature of 550°C for 10 hours to obtain (Na 0.5 Bi 0.49 Er 0.01 )TiO 3 Polycrystalline material; the obtained polycrystalline material is finely ground and sieved, and a certain proportion of Bi is added based on the total amount of polycrystalline material 2 o 3 As a single ...

Embodiment 2

[0029] Na with a purity greater than 99.99% 2 CO 3 、 Bi 2 o 3 、TiO 2 and Er 2 o 3 After the powder is fully dried, according to the general formula (Na 0.5 Bi 0.47 Er 0.03 )TiO 3 ,in x =0.03, accurately weigh the powders of the stoichiometric ratio, and ball mill them for 15 hours to make them evenly mixed; put the mixture in a platinum crucible, and put the platinum crucible into a container filled with Bi 2 o 3 and Na 2 CO 3 Powder in the covered corundum crucible, where Bi 2 o 3 Powder, Na 2 CO 3 The molar ratio of the powder to the mixture in the platinum crucible is 0.5:0.5:1; the corundum crucible is placed in a muffle furnace and sintered at a temperature of 600°C for 10 hours to obtain (Na 0.5 Bi 0.47 Er 0.03 )TiO 3 TiO 3 Polycrystalline material; the obtained polycrystalline material is finely ground and sieved, and a certain proportion of Bi is added based on the total amount of polycrystalline material 2 o 3 As a single flux, where Bi 2 o 3 ...

Embodiment 3

[0032] Na with a purity greater than 99.99% 2 CO 3 、 Bi 2 o 3 、TiO 2 and Er 2 o 3 After the powder is fully dried, according to the general formula (Na 0.5 Bi 0.45 Er 0.05 )TiO 3 ,in x =0.05, accurately weigh the powders of the stoichiometric ratio, and ball mill them for 20 hours to make them evenly mixed; put the mixture in a platinum crucible, and put the platinum crucible into a container filled with Bi 2 o 3 and Na 2 CO 3 Powder in the covered corundum crucible, where Bi 2 o 3 Powder, Na 2 CO 3 The molar ratio of the powder to the mixture in the platinum crucible is 0.8:0.8:1; the corundum crucible is placed in a muffle furnace and sintered at a temperature of 700°C for 10 hours to obtain (Na 0.5 Bi 0.45 Er 0.05 )TiO 3 Polycrystalline material; the obtained polycrystalline material is finely ground and sieved, and a certain proportion of Bi is added based on the total amount of polycrystalline material 2 o 3 As a single flux, where Bi 2 o 3 :(Na 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com