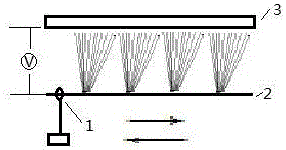

Electrostatic spinning device containing wire electrode and nano-fiber preparation method

A filamentary electrode, electrospinning technology, applied in electrospinning, fiber processing, filament/line forming and other directions, can solve the problems of low nanofiber efficiency, easy clogging of electrodes, etc., to improve preparation efficiency and production efficiency The effect of raising and thinning the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

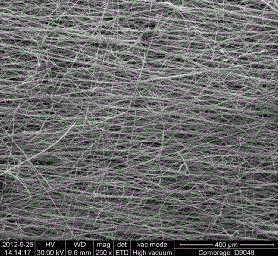

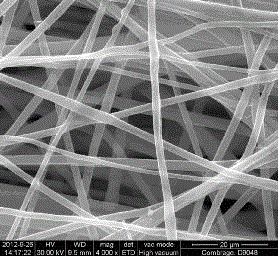

[0019] Use a single copper wire with a diameter of 0.5mm as a wire electrode, prepare 8% polyvinyl alcohol (PVA) aqueous solution according to the technical specification of 400mm, and control parameter conditions: the distance between the electrode and the receiving substrate is 15cm, the voltage is 30KV, and the feeding system The reciprocating speed is 0.01m / s, the output speed is 3ml / h, and the moving speed of the conveyor belt is 0.1m / s. The PVA nanofiber membrane is collected and the spinning efficiency is significantly improved compared with a single nozzle electrode.

[0020] The electron micrograph of the present embodiment product nanofiber scanning magnification 200 times is as figure 2 As shown, the nanofiber scanning electron microscope photo with a magnification of 4000 times is as follows image 3 shown.

Embodiment 2

[0022] Use a single copper wire with a diameter of 0.5mm as a filamentary electrode, and build an electrospinning device according to the method described in the technical plan. The electrode length is 400mm, and a DMF solution of 10% polyacrylonitrile (PAN) is prepared. Control parameter conditions: electrode and The distance between the receiving substrates is 15cm, the voltage is 10KV, the reciprocating speed of the feeding system is 0.01m / s, the discharging speed is 3ml / h, and the moving speed of the transmission belt is 0.1m / s, and the PAN nanofiber film is collected.

Embodiment 3

[0024] Use a single copper wire with a diameter of 0.5mm as a wire electrode, build an electrospinning device according to the method described in the technical plan, the electrode length is 400mm, prepare a DMF solution of 15% polylactic acid (PLA), control parameter conditions: electrode and receiver The distance between the substrates is 20cm, the voltage is 25KV, the reciprocating speed of the feeding system is 0.01m / s, the output speed is 3ml / h, and the moving speed of the conveyor belt is 0.1m / s, and the PLA nanofiber film is collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com