Yilon/cotton blended weft plain stitch knitted fabric and preparation method thereof

A knitted fabric and cotton blending technology, applied in the field of clothing fabrics, can solve the problems of no hydrophilic group and poor hygroscopicity, and achieve the effects of soft hand feeling, good performance and shortening the finishing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Yilun / cotton blended weft flat knitted fabric, its preparation comprises the following steps:

[0038] (1) Selection of yarn: 28 yarns prepared by Siro compact spinning process S Yilun / cotton (65 / 35) blended yarn, yarn twist 71.77 twist / 10cm, twist coefficient 329. That is, the yarn count of Yilun / cotton blended yarn is 28 S , wherein the mass ratio of Yilun and cotton is 65:35.

[0039] (2) Knitting and weaving process: knitting weft plain knitted fabric on a circular weft machine with a machine number of E24, the horizontal density of the fabric is 70 coils / 5cm, the vertical density of the lower machine is 90 coils / 5cm, and the square meter weight of the blank is 130g / m 2 , coil length 28.5cm / 100 coils.

[0040] (3) Post-finishing process: The process of this post-finishing process is: rough shaping → pre-treatment → dyeing → moisture absorption and quick-drying and antibacterial function finishing → finished product finalizing.

[0041] in:

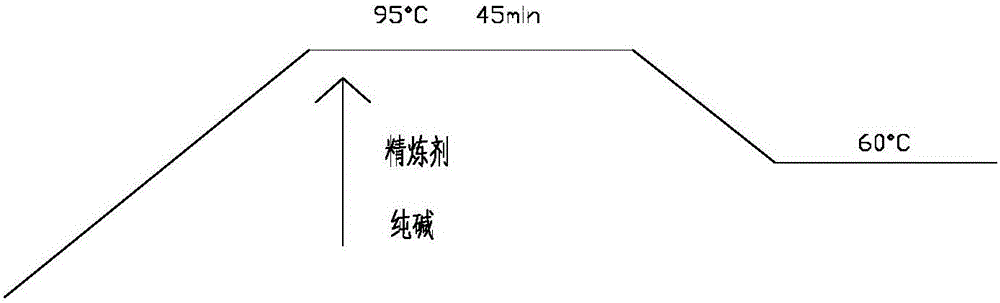

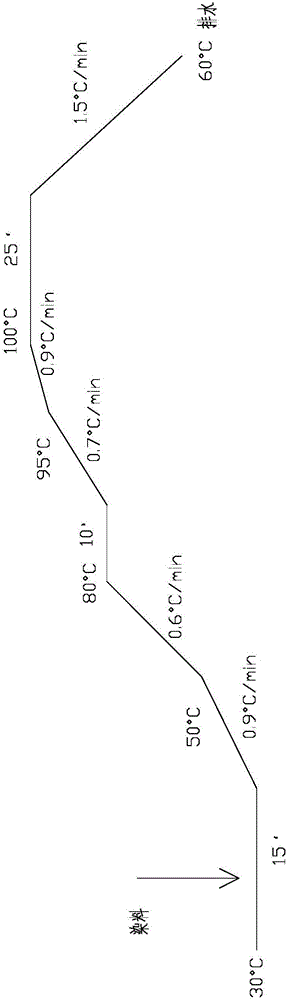

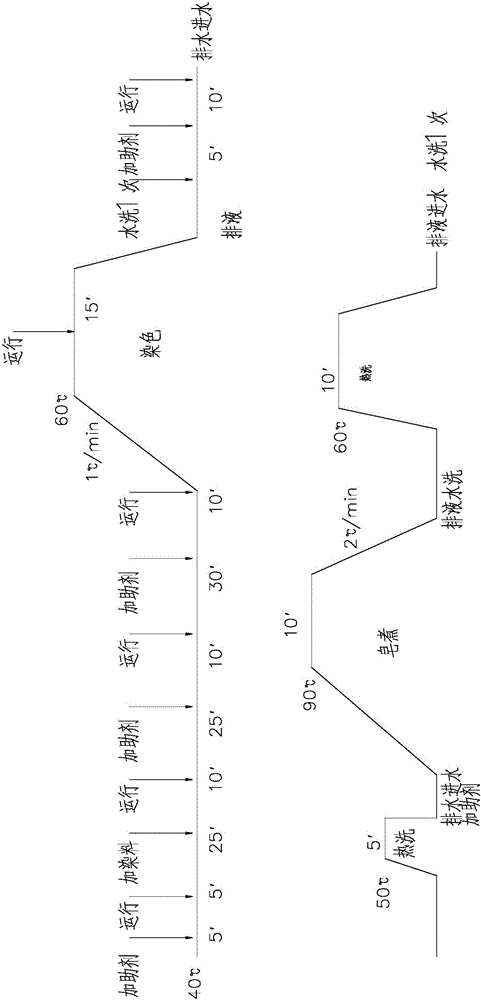

[0042] (a) blank sh...

Embodiment 2

[0090] Compared with the aforementioned Example 1, the blank shaping, pretreatment, dyeing and finished product heat setting processes in yarn, knitting and finishing are unchanged, and only the fabric moisture absorption and perspiration and antibacterial function finishing processes are changed.

[0091] The padding solution of moisture absorption perspiration and antibacterial function finishing of the present embodiment is:

[0092] Moisture wicking agent: 30g / L, using NH-D20

[0093] Antibacterial finishing agent: 60g / L, using methyldimethoxysilane quaternary ammonium salt: polyhexamethylene biguanide hydrochloride, and combined at a molar ratio of 5:1

[0094] Penetrant JFC: 3g / L.

[0095] Liquid content of working fluid: 65%.

[0096] Hot air drying temperature: 90°C.

[0097] Hot air drying time: 2.5min.

[0098] Baking temperature: 150°C.

[0099] Baking time: 1min.

[0100] The Yilun / cotton blended weft jersey knitted fabric produced by the above method was lef...

Embodiment 3

[0106] Compared with the aforementioned Example 1, the gray cloth setting, pretreatment, dyeing and finished product setting processes in the yarn, knitting and finishing are unchanged, and only the fabric moisture absorption and perspiration and antibacterial function finishing processes are changed.

[0107] The padding solution of moisture absorption perspiration and antibacterial function finishing of the present embodiment is:

[0108] Moisture wicking agent: 60g / L, using TF-620

[0109]Antibacterial finishing agent: 40g / L, using N,N-dimethyldodecylaminopropyltrimethoxysilane Ammonium chloride: 1,1'-hexamethylenebis[5-(-4-chlorobenzene base) biguanide] gluconate, and combined in a molar ratio of 4.5:1

[0110] Penetrant JFC: 1g / L.

[0111] Liquid content of working fluid: 75%.

[0112] Hot air drying temperature: 100°C.

[0113] Hot air drying time: 1.5min.

[0114] Baking temperature: 135°C.

[0115] Baking time: 1.5min.

[0116] The Yilun cotton blended weft jers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com