Oil-water separation fiber membrane with excellent anti-pollution capability and preparation method thereof

An oil-water separation membrane and fiber technology, which is used in fiber processing, non-woven fabrics, textiles and papermaking, etc., can solve the problems of complex preparation and modification process, low membrane water flux, limited improvement, etc., and achieve high mechanical strength. , The effect of good separation effect and huge application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

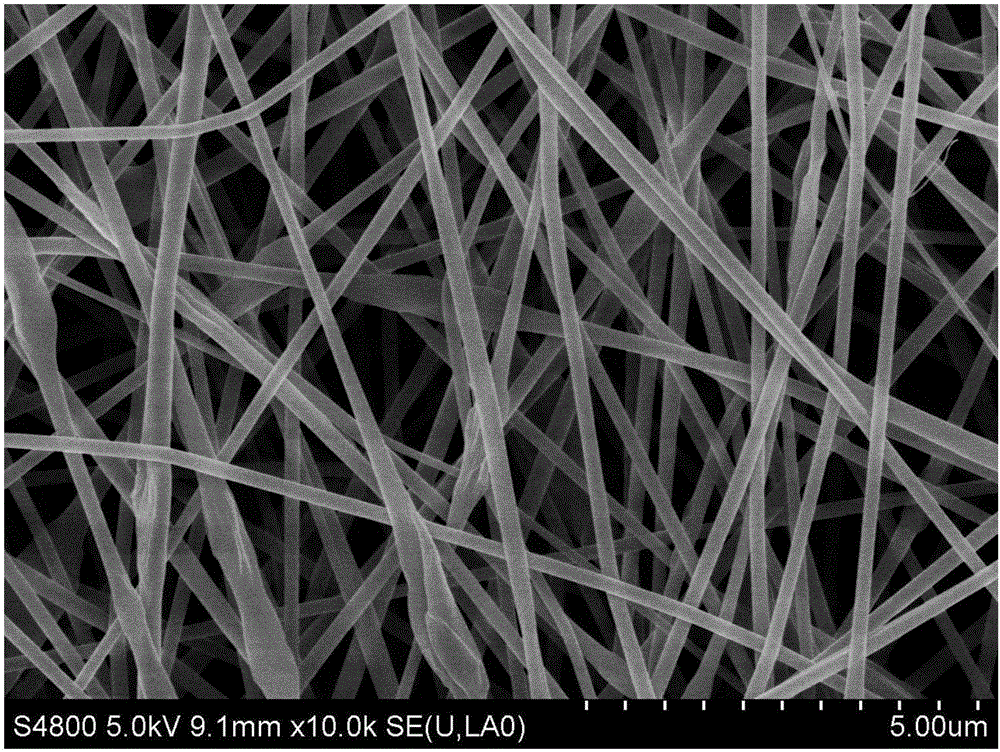

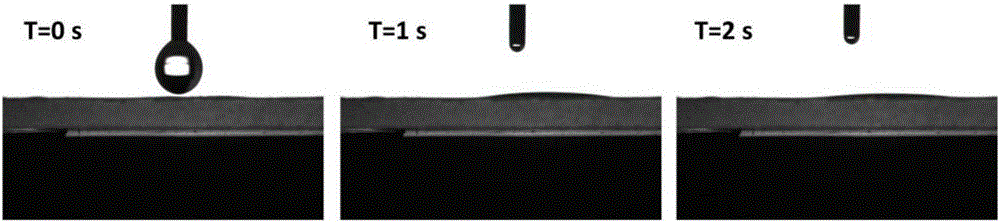

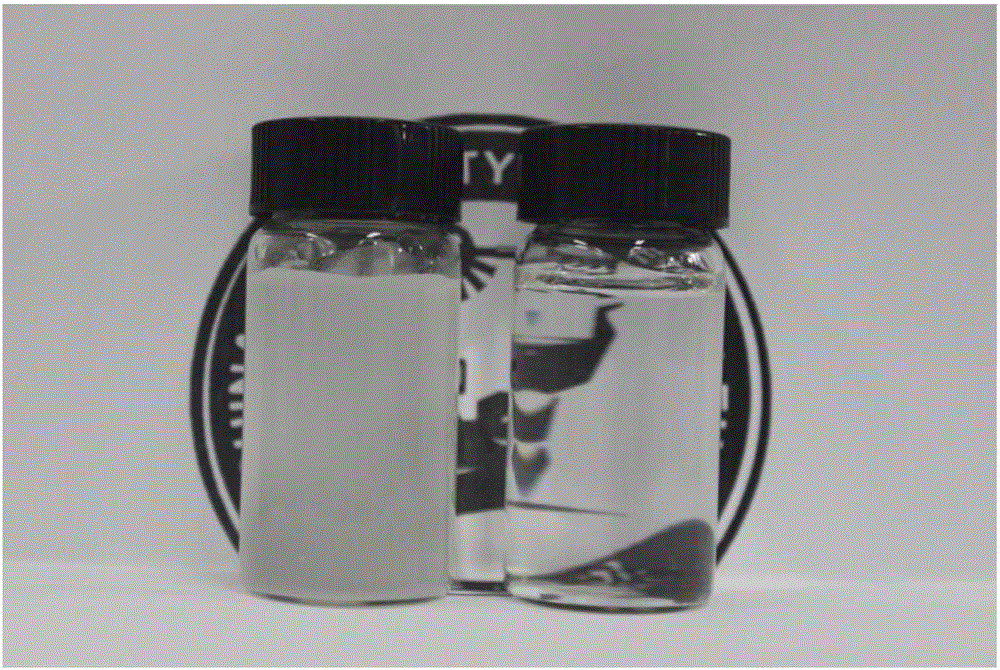

[0016] Example 1, 5 ml of dimethylformamide solution was taken, 0.525 g of polyacrylonitrile was added into the dimethylformamide solution, and magnetically stirred at room temperature for 6 hours to obtain a uniformly mixed solution. Take 5 ml of dimethylformamide solution, add 150 g of graphene oxide into the dimethylformamide solution, and disperse in ultrasonic for 2 hours to obtain a uniform mixed solution. 1.75 ml of graphene oxide dispersion was added to the polyacrylonitrile solution, and magnetically stirred for 6 hours to obtain a uniformly mixed solution. Inhale 3ml of solution into a 5ml syringe and install a 20-gauge needle. Put the syringe into the syringe pump of the electrospinning equipment, adjust the advancing speed of the syringe pump to 1ml per hour, and adjust the distance from the needle to the receiver to 8~ 15 cm. Cover the roller receiver with a layer of tinfoil, and adjust the receiver rotation speed to 60 revolutions per minute. Connect the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com