Method for increasing moisture permeability of superfine fiber synthetic leather

A water vapor permeability and microfiber technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problem of low water vapor permeability of base fabrics, and achieve resource utilization, tensile strength improvement, and water vapor permeability improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Sulfuric acid treatment of base cloth

[0026] Put the base cloth with a dry weight of 10.5g in a drum at 50°C, add 525g of water and 1.05g of sulfuric acid, heat it for 2h, wash it thoroughly with water, and dry it in an oven at 80°C for 2h.

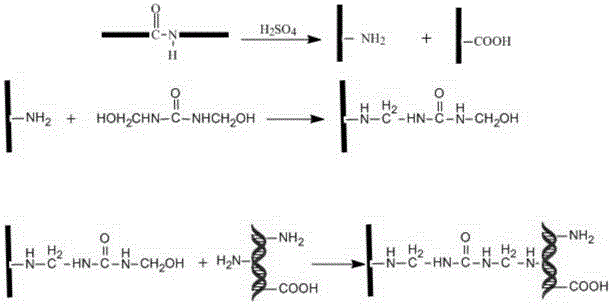

[0027] (2) Urea-formaldehyde resin treatment of base cloth

[0028] Put the pretreated base cloth in the drum, add urea-formaldehyde resin to 8% of the dry weight of the base cloth, that is, 0.84g, add water 315g, add 5% of the total amount of urea-formaldehyde resin and collagen, that is, 0.095g Catalyst ZnSO 4 , use glacial acetic acid to adjust the pH of the mixed bath to 4.5, treat it in the infrared sample dyeing machine at 45°C for 2 hours, then stop, take it out, and wash it thoroughly with water.

[0029] (3) Collagen grafting

[0030] Add 10% of the dry weight of the base cloth treated with urea-formaldehyde resin, that is, 1.05g of collagen, add 315g of water, and treat it in an infrared sample dyeing machine at ...

Embodiment 2

[0034] (1) Sulfuric acid treatment of base cloth

[0035] Put the base cloth with a dry weight of 10.0g in a drum at 40°C, add 500g of water and 1.2g of sulfuric acid, heat for 3 hours, wash it thoroughly with water, and dry it in an oven at 80°C for 2 hours.

[0036] (2) Urea-formaldehyde resin treatment of base cloth

[0037] Put the base cloth pretreated by sulfuric acid in the drum, add 10% of the dry weight of the base cloth, that is, 1.0g of urea-formaldehyde resin, add 300g of water, add 5% of the total amount of urea-formaldehyde resin and collagen, that is, 0.11 g Catalyst ZnSO 4 , use glacial acetic acid to adjust the pH of the mixed bath to 4.5, treat it in the infrared sample dyeing machine at 45°C for 1.5h, then stop, take it out, and wash it thoroughly with water.

[0038] (3) Collagen grafting

[0039] Add 12% of the dry weight of the base cloth treated with urea-formaldehyde resin, that is, 1.2 g of collagen, add 300 g of water, and treat it in the infrared ...

Embodiment 3

[0043] (1) Sulfuric acid treatment of base cloth

[0044] Put the base cloth with a dry weight of 10.3g in a drum at 45°C, add 515g of water and 1.545g of sulfuric acid, heat it for 2.5h, wash it fully with water, and dry it in an oven at 80°C for 2h.

[0045] (2) Urea-formaldehyde resin treatment of base cloth

[0046] Put the pretreated base cloth in the drum, add 10% of the dry weight of the base cloth, that is, 1.03g of urea-formaldehyde resin, add 309g of water, add 5% of the total amount of urea-formaldehyde resin and collagen, that is, 0.11g Catalyst ZnSO 4 , use glacial acetic acid to adjust the pH of the mixed bath solution to 5, treat it in the infrared sample dyeing machine at 50°C for 1 hour, then stop, take it out, and wash it thoroughly with water.

[0047] (3) Collagen grafting

[0048] Add 11% of the dry weight of the base cloth treated with urea-formaldehyde resin, that is, 1.133g of collagen, add 309g of water, and treat it in the infrared sample dyeing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com