Cold storage wall and construction method

A refrigerator and wall technology, applied to the field of refrigerator walls, can solve the problems of poor thermal insulation effect, condensate water, damage to the wall structure, etc., and achieve the effects of saving cost and time, good adhesion, and improving thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

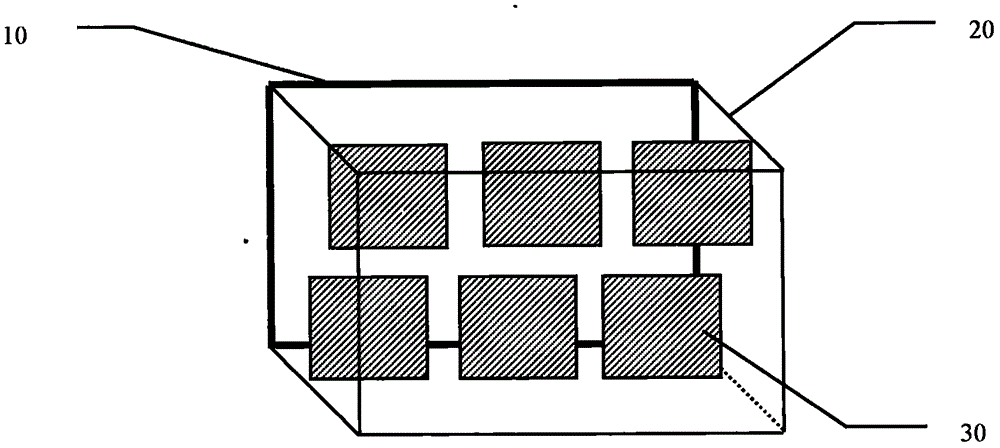

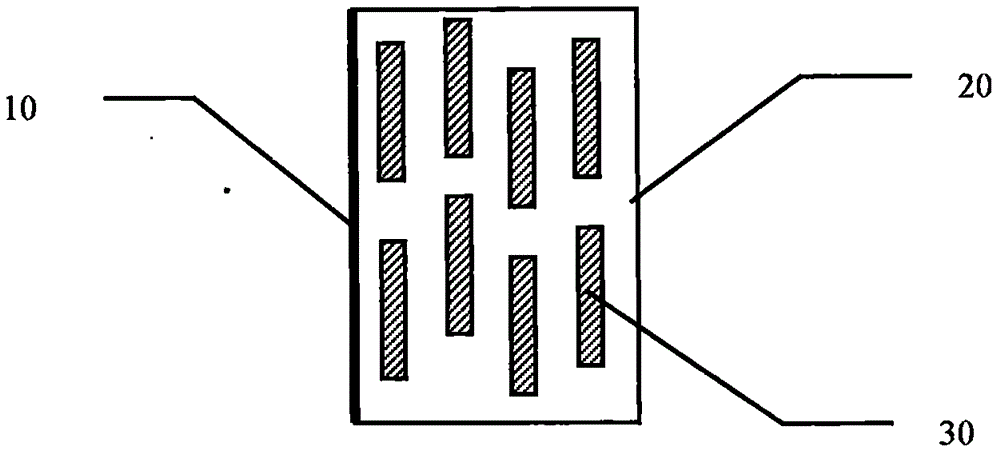

[0022] A refrigerator wall, which is characterized in that it is composed of a base wall, a polyurethane foam layer and a vacuum insulation panel, wherein polyurethane foam layers of different thicknesses are embedded in vacuum insulation panels at intervals, and the vacuum insulation panels of each thickness layer are also arranged at intervals; The thickness of the polyurethane foam layer is 10mm, wherein the polyurethane foam layer is composed of material A and material B with a volume ratio of 1:1; the thickness of the vacuum insulation panel is 8mm.

[0023] The material A of the polyurethane foam layer is isocyanate, and the material B is polyester polyol and auxiliary agent, wherein the polyester polyol is polycondensed by at least one of phthalic acid and ethylene glycol, glycerol, and trimethylol propane made.

[0024] Described auxiliary agent comprises that the percentage of component mass accounting for the total mass of polyester polyol component is respectively 8...

Embodiment 2

[0031] A refrigerator wall, which is characterized in that it is composed of a base wall, a polyurethane foam layer and a vacuum insulation panel, wherein polyurethane foam layers of different thicknesses are embedded in vacuum insulation panels at intervals, and the vacuum insulation panels of each thickness layer are also arranged at intervals; The thickness of the polyurethane foam layer is 100mm, wherein the polyurethane foam layer is composed of material A and material B with a volume ratio of 1:1.3; the thickness of the vacuum insulation panel is 25mm.

[0032] The material A of the polyurethane foam layer is isocyanate, and the material B is polyester polyol and auxiliary agent, wherein the polyester polyol is polycondensed by at least one of phthalic acid and ethylene glycol, glycerol, and trimethylol propane made.

[0033] Described auxiliary agent comprises that the percentage of component mass accounting for the total mass of polyester polyol component is respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com