Method for preparing high-sensitivity low working temperature ethanol gas sensor element

A gas sensor, working temperature technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as unfavorable low-power device research, unfavorable environmental protection, reducing material resistance, etc., to increase the content and the ability to adsorb oxygen, Reduce particle size and agglomeration phenomenon, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

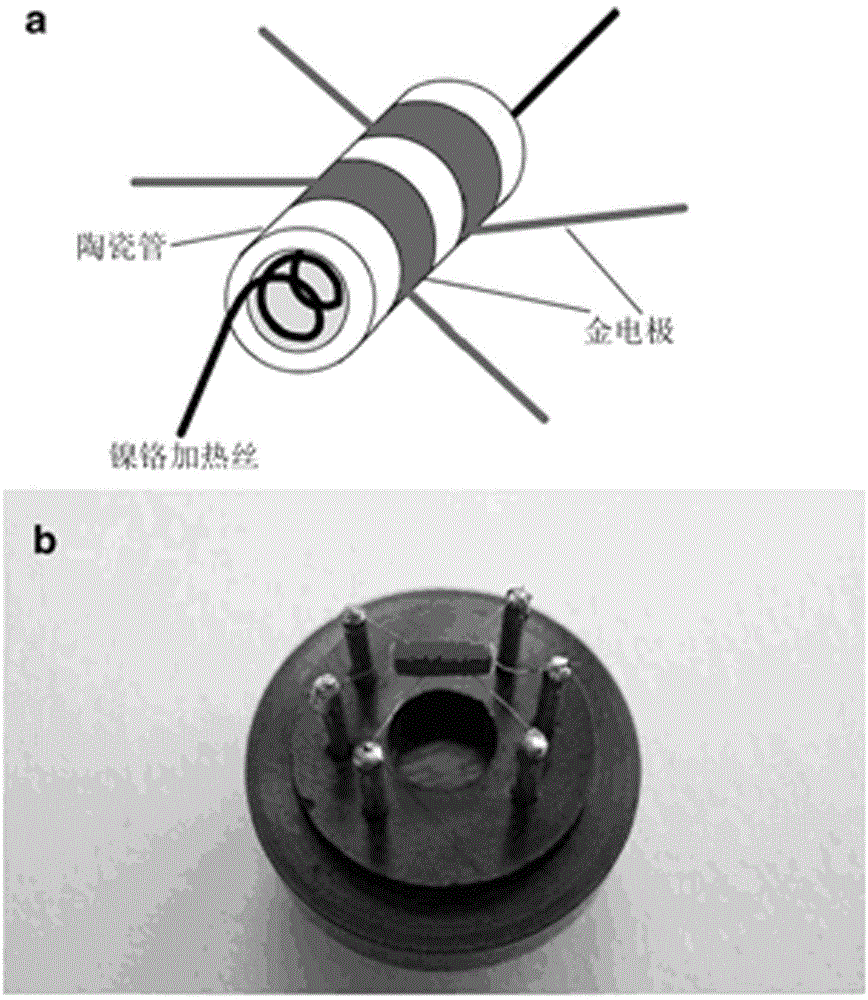

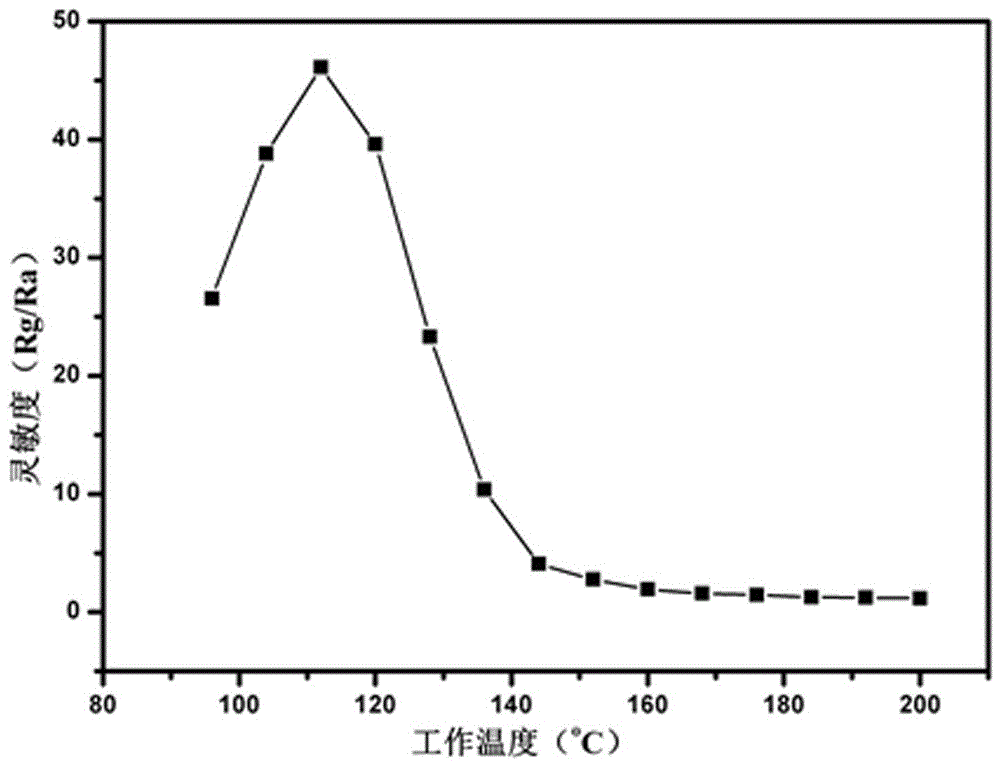

Image

Examples

Embodiment 1

[0032] (1) Precursor ingredients

[0033] According to the stoichiometric ratio La:Fe=1:1, accurately weigh 0.03mol of La(NO 3 ) 3 ·6H 2 O and 0.03mol Fe(NO 3 ) 3 9H 2 O;

[0034] (2) Preparation of xerogel

[0035] Dissolve the precursor ingredients in deionized water, add 0.12mol citric acid to make a mixed solution according to the molar ratio of the sum of cations and citric acid being 1:2, add ammonia water to adjust the pH to 7, and place the mixed solution in a water bath at 80°C Stir, add ethylene glycol EG (ethylene glycol EG: total cation = 1:2) to form a sol according to the molar ratio of 1:2 to the sum of cations, and continue stirring until the dry gel state;

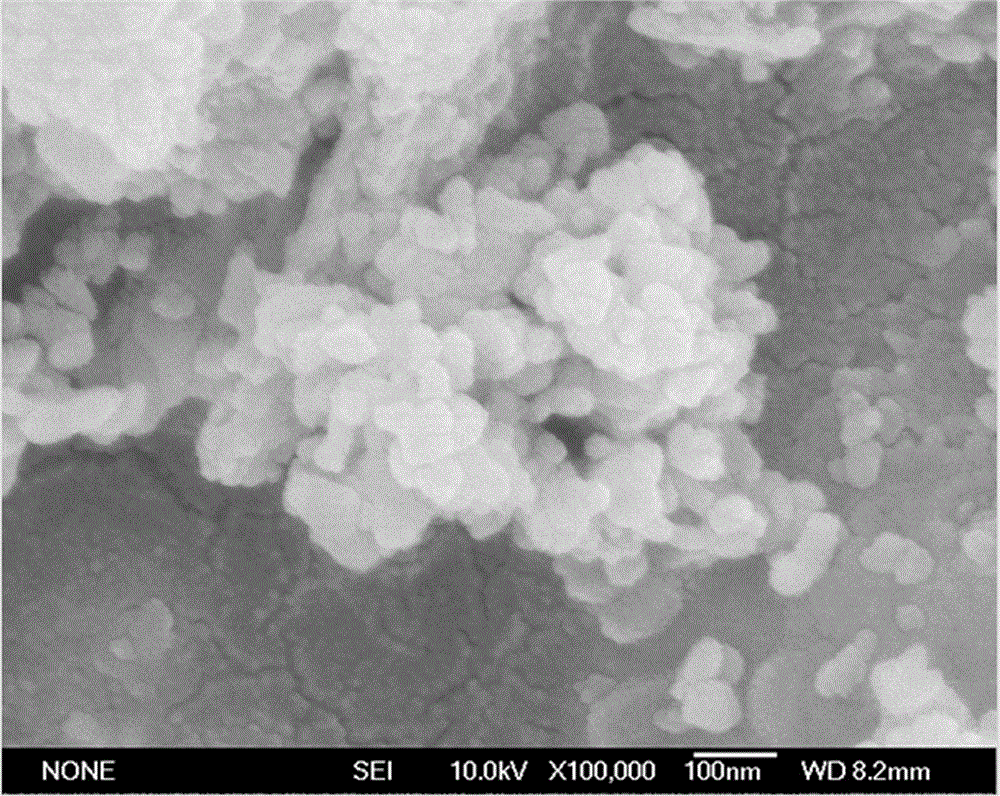

[0036] (3) LaFeO 3 Preparation of Nanopowder

[0037] Put the dry gel into a crucible to heat to produce spontaneous combustion. The obtained powder is ground and placed in a muffle furnace, and sintered at 400°C for 2 hours to remove residual organic matter; the obtained powder is manually ground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com