Method for manufacturing self-aligned silicide barrier layer

A technology of self-aligned silicide and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems that affect device performance and yield, design index threshold voltage shift, and cannot be completely removed. Achieve the effect of taking into account the etching rate and etching uniformity, improving device performance and product yield, and avoiding design index deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose and features of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

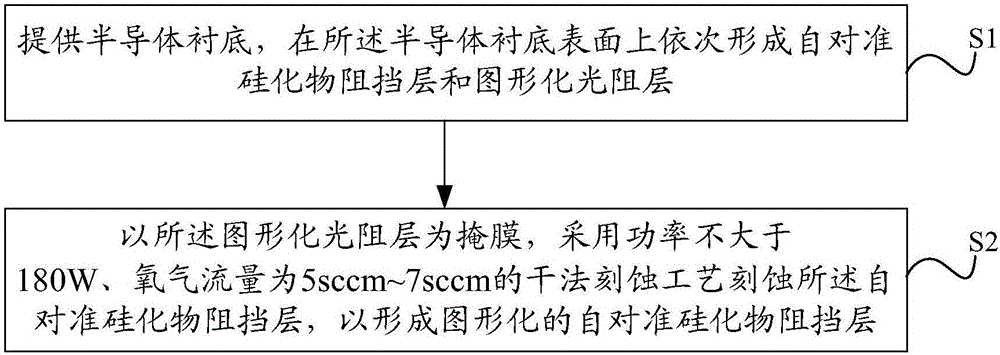

[0027] Please refer to figure 2 , the present invention provides a method for manufacturing a salicide barrier layer, comprising the following steps:

[0028] S1, providing a semiconductor substrate, sequentially forming a salicide barrier layer and a patterned photoresist layer on the surface of the semiconductor substrate;

[0029] S2, using the patterned photoresist layer as a mask, using a dry etching process with a power not greater than 180W and an oxygen flow rate of 5 sccm to 7 sccm to etch the salicide barrier layer to form a patterned self-aligned silicide barrier layer. alignment silicide barrier layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com