Heterojunction semiconductor laser and manufacturing method thereof

A heterojunction and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of large beam divergence angle, large temperature influence, poor directionality, monochromaticity and coherence, etc., and achieve easy lattice The effect of matching, reducing injection current, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

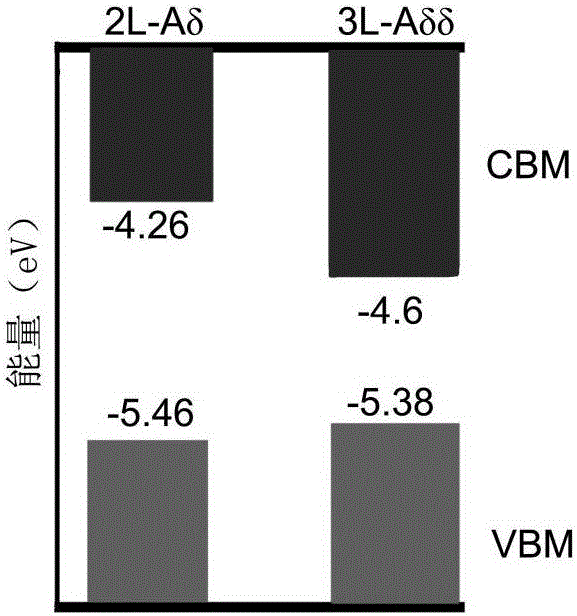

Examples

Embodiment Construction

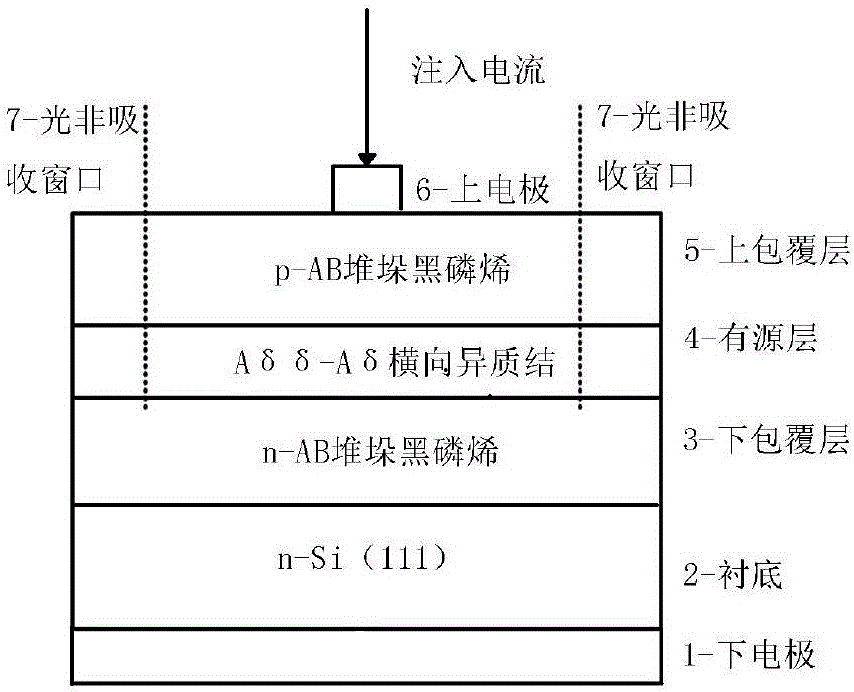

[0032] a. Preparation of the substrate: using n-type silicon as the substrate;

[0033] n-Si substrate cleaning: take n-Si (111) sheet as the substrate, soak it with olefinic HF acid to remove the silicon dioxide on the Si surface, and then use propanol, ethanol, and deionized water to ultrasonically clean it to remove the silicon dioxide on the silicon sheet. Dry the organic matter with nitrogen, and put it into a quartz tube for deposition treatment; the vacuum degree of the quartz tube is about 10-2Pa, and it is heated to about 300°C for 10-15 minutes to remove the water vapor on the surface of the silicon wafer;

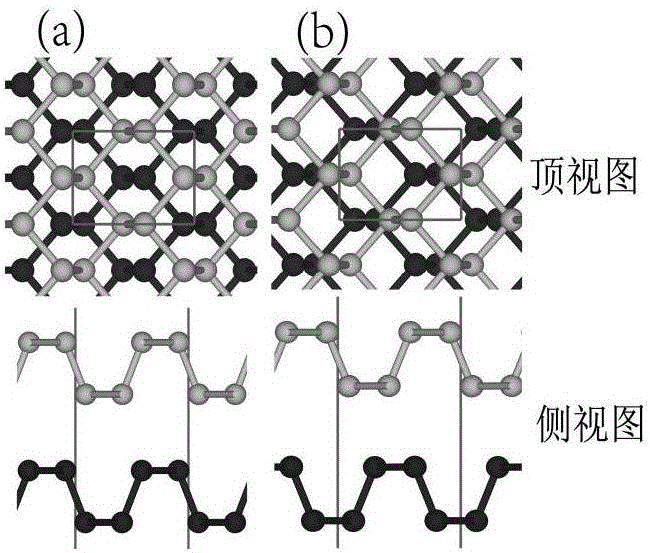

[0034] b. Preparation of few-layer black phosphorene: Bulk black phosphorus is obtained by treating its isomorph white phosphorus or red phosphorus under high temperature and high pressure:

[0035] 1) White phosphorus was heated to 200°C at 1200 atmospheres to obtain flaky black phosphorus; the multi-layer black phosphorene was peeled off from the black phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com