Semiaromatic polyamide resin composition and molded body obtained by molding same

A polyamide resin and semi-aromatic technology, which is applied in the field of semi-aromatic polyamide resin compositions, can solve the problems of physical property degradation, thermal aging, and retention stability, and achieve fluidity improvement, thermal aging suppression, and retention stability The effect of sexual decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples.

[0094] 1. Measurement method

[0095] The physical properties of the semi-aromatic polyamide and the semi-aromatic polyamide resin composition were measured by the following methods.

[0096] (1) Melting point

[0097] Using a differential scanning calorimeter DSC-7 type (manufactured by Perkin Elmer Co.), the temperature was raised to 370° C. at a heating rate of 20° C. / min under a nitrogen atmosphere, kept at 370° C. for 5 minutes, and cooled at a cooling rate of 20° C. / min. After reaching 25°C and further maintaining at 25°C for 5 minutes, the peak top of the endothermic peak obtained when the temperature was raised again at a heating rate of 20°C / min was measured as the melting point.

[0098] (2) relative viscosity

[0099] Measurement was performed at a concentration of 1 g / dL at 25° C. using 96% by mass sulfuric acid as a solvent.

[010...

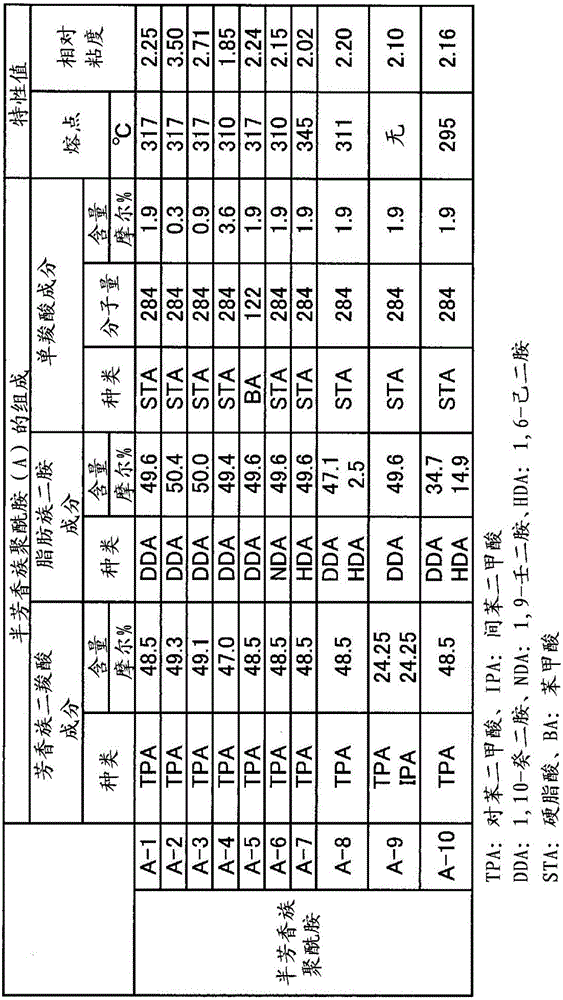

manufacture example 1

[0169] ·Semi-aromatic polyamide (A-1)

[0170] 4.70 kg of powdered terephthalic acid (TPA) as an aromatic dicarboxylic acid component, 0.32 kg of stearic acid (STA) as a monocarboxylic acid component, and 9.3 g of sodium hypophosphite monohydrate as a polymerization catalyst Put it into a ribbon mixing reaction apparatus, and heat to 170 degreeC, stirring at 30 rpm under nitrogen sealing. Thereafter, 4.98 kg of 1,10-decanediamine (DDA) heated to 100° C. as an aliphatic diamine component was injected using a liquid injection device while maintaining the temperature at 170° C. and the rotational speed at 30 rpm. The addition was continued (continuous liquid injection system) over 2.5 hours to obtain a reaction product. The molar ratio of the raw material monomers is TPA:DDA:STA=48.5:49.6:1.9 (the equivalent ratio of the functional groups of the raw material monomers is TPA:DDA:STA=49.0:50.0:1.0).

[0171] Next, the obtained reaction product was heated and polymerized in the sa...

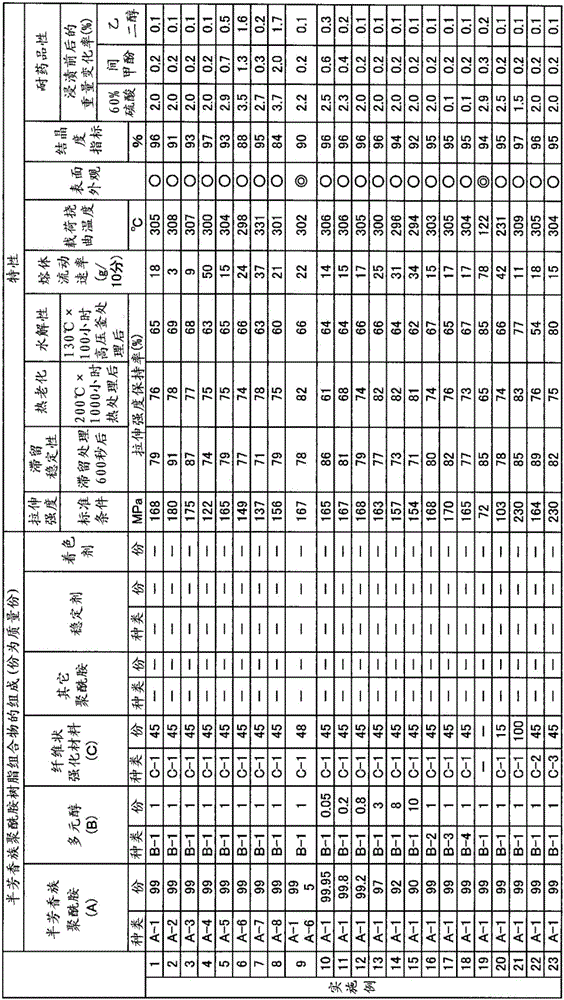

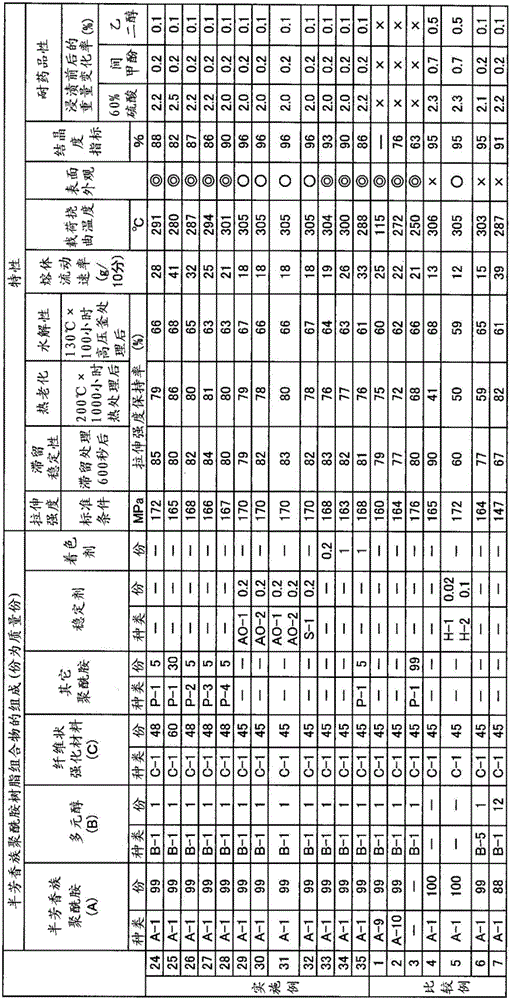

Embodiment 1

[0179] 99 parts by mass of semi-aromatic polyamide (A-1) and 1 part by mass of polyol (B-1) were dry-blended, and a continuous quantitative supply device CE-W-1 (Kubota Co., Ltd.) was measured, supplied to the main feed port of a co-rotating twin-screw extruder TEM26SS type (Toshiba Machine Co., Ltd.) with a screw diameter of 26 mm and L / D50, and melt-kneaded. On the way, 45 parts by mass of the fibrous reinforcement (C-1) was supplied from the side feed port, and kneaded further. After being drawn into a linear shape from a die, it was cooled and solidified by passing through a water tank, and cut with a pelletizer to obtain semi-aromatic polyamide resin composition pellets. The barrel temperature of the extruder was set to (melting point of semi-aromatic polyamide + 5°C) to (melting point of semi-aromatic polyamide + 15°C), the screw speed was set to 250 rpm, and the discharge rate was set to 25 kg / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com