Gas supply system and hydrogen station

A gas supply and gas technology, applied in the field of gas supply system and hydrogen refueling station, can solve the problems of enlarging the setting area of the first support platform, enlarging the hydrogen compression device, enlarging the hydrogen refueling station, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

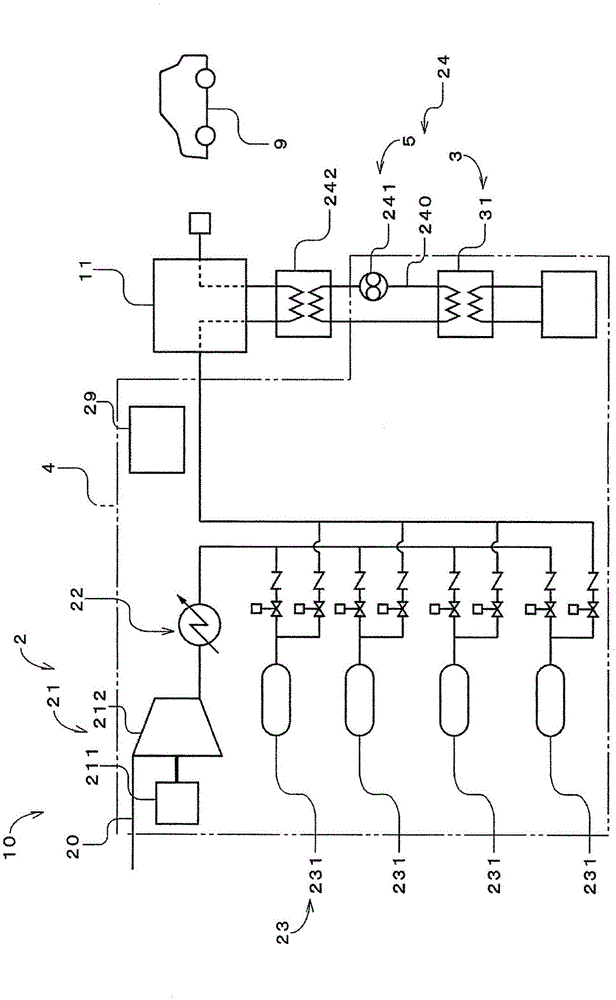

[0029] figure 1 It is a figure which shows the hydrogen refueling station 10 which concerns on 1st Embodiment of this invention. The hydrogen refueling station 10 includes a gas supply system 2 and a distributor 11 as a filling device. The gas supply system 2 supplies hydrogen gas to the distributor 11 . The dispenser 11 fills the vehicle 9 as a tank-mounted device with hydrogen gas. Vehicle 9 is, for example, a fuel cell vehicle. The gas supply system 2 includes a gas flow path 20 , a compressor assembly 21 , a gas cooling unit 22 , an accumulator assembly 23 , a precooling system 24 , a casing 4 and a control unit 29 indicated by dashed-two dotted lines. The compressor assembly 21 , a part of the gas cooling unit 22 , and the accumulator assembly 23 are arranged on the gas flow path 20 . Hydrogen gas flows toward the distributor 11 in the gas flow path 20 . The controller 29 controls the compressor assembly 21 , the accumulator assembly 23 and the precooling system 24 ....

Embodiment approach

[0058] As mentioned above, although the 1st Embodiment of this invention was described, this invention is not limited to the said 1st Embodiment, Various changes are possible.

[0059] exist Figure 9 In the hydrogen refueling station 10 a shown, the pre-cooling heat exchanger 242 can also be arranged in the casing 4 . In addition, in figure 1In the gas supply system 2 shown, the pre-cooling heat exchanger 242 may also be arranged in the cabinet 4 . At this time, all the equipment of the compressor assembly 21 , the gas cooling unit 22 , the accumulator assembly 23 , and the precooling system 24 are arranged inside the cabinet 4 or the upper part 42 of the cabinet 4 . A cover for covering the heat exhaust unit 223 and the condensation unit 33 may be attached to the upper part 42 and all the devices may be arranged in the cabinet 4 .

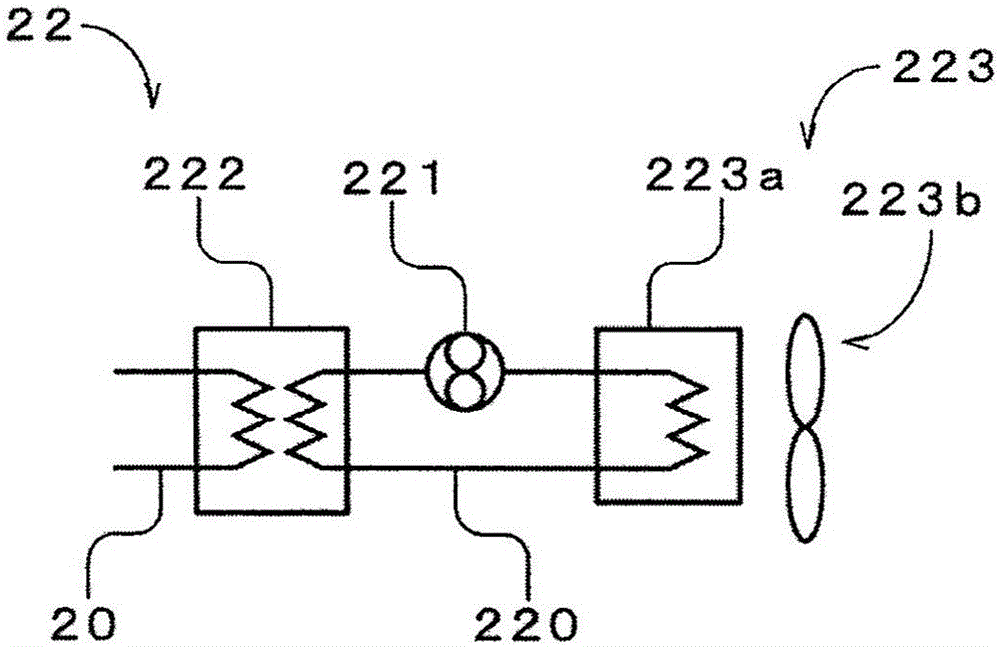

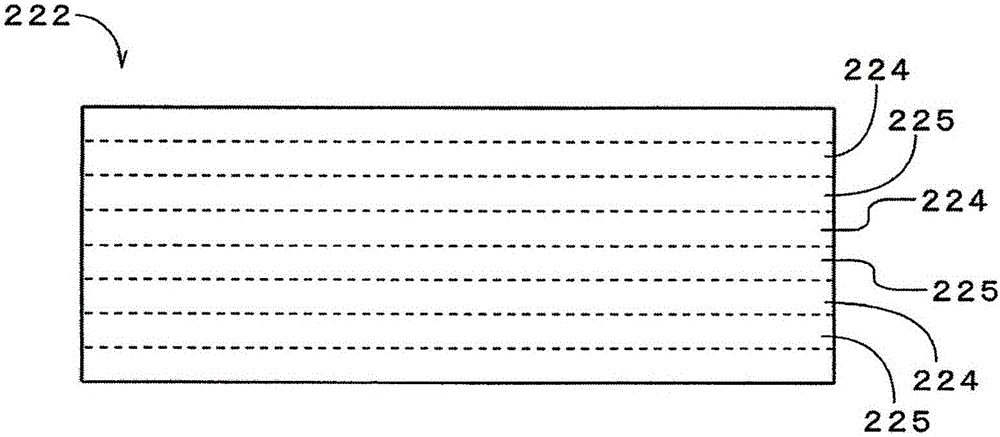

[0060] The gas cooler 222 may be a plate heat exchanger other than a microchannel heat exchanger as long as it is directly fixed to the compr...

no. 2 approach

[0077] The gas supply system 2 according to the second embodiment of the present invention will be described. Here, only configurations different from those of the first embodiment will be described, and descriptions of configurations that are the same as those of the first embodiment will be omitted. in addition, Figure 1 to Figure 6 It is also used as a diagram showing the gas supply system according to the second embodiment.

[0078] Figure 10 is a side view of the gas supply system 2 . Figure 11 From Figure 10 The left side view of the diagram of the gas supply system 2. exist Figure 10 and Figure 11 In , the casing 4 is represented by a two-dot dash line. In addition, only the main equipment of the gas supply system 2 is shown, and the illustration of peripheral components such as piping is omitted. exist Figure 10 and Figure 11 in, will figure 1 The brine pump 241 of the precooling system 2 shown, the evaporator 31 of the refrigerator 3, Figure 6 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com