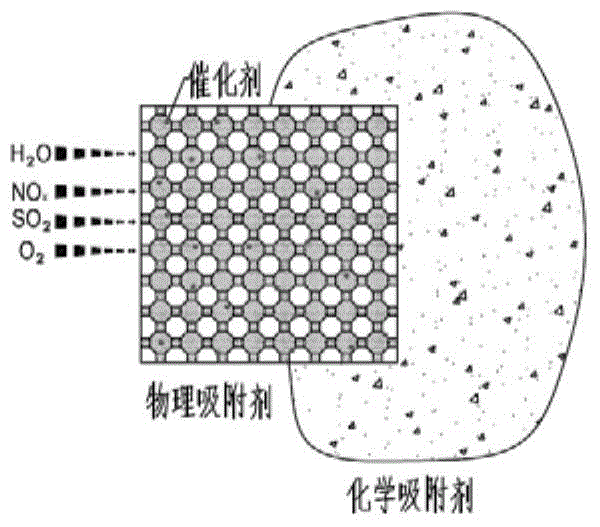

Composite adsorbent

A composite adsorption and physical adsorbent technology, applied in the direction of silicon compounds, silicates, inorganic chemistry, etc., can solve the problems of cheap and expensive adsorbents, affecting air quality, etc., and achieve the effect of fixing and final removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mix activated carbon, calcium oxide and asphalt uniformly in a weight ratio of 1:1:0.3, wherein the porosity of the activated carbon is 0.6, and the resulting mixture is pressed into a ball with a diameter of 30mm at 250°C, and after cooling, a composite adsorption Agent 1 has a porosity of 0.44.

Embodiment 2

[0046] Mix SAPO-34 molecular sieve with calcium oxide and aluminum sol in a weight ratio of 0.4:1:0.1 (aluminum sol is calculated on a dry basis), wherein the porosity of SAPO-34 is 0.5, and a certain amount of water is added to the resulting mixture to form Paste, the obtained paste was dried at 140° C. for 24 hours, and after cooling, it was mechanically crushed into particles with a particle size of about 1 mm to obtain composite adsorbent 2 with a porosity of 0.38.

Embodiment 3

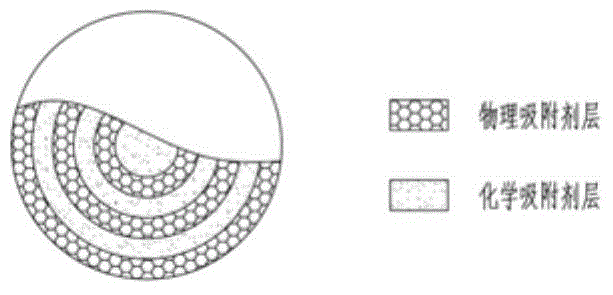

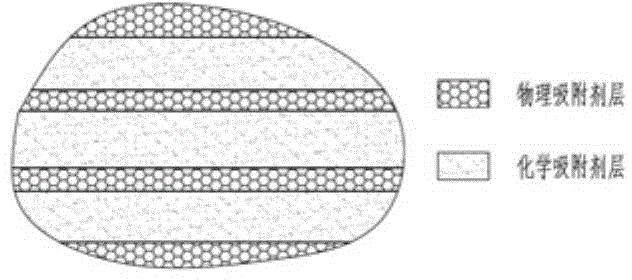

[0048] Mix 4A molecular sieve and SAPO-15 molecular sieve uniformly in a weight ratio of 2:3 as powder I, wherein the porosity of 4A molecular sieve and SAPO-15 molecular sieve are 0.45 and 0.48 respectively; use limestone powder as powder II; use water glass As a binder; use the rolling ball method to spray the binder into the powder II and roll it into a ball, add the prepared ball to the powder I and roll it into a ball while spraying the binder, and then add it to the powder II Repeat rolling into ball operation several times, finally finish rolling into ball process in powder I; Powder I consumed in rolling into ball process: powder II: the weight ratio of binding agent (dry basis) is 0.5:1:0.3, makes A multi-layered sphere with a diameter of 20-50 mm was obtained; dried at 150° C. for 20 h, and calcined at 500° C. for 4 h under a nitrogen atmosphere to obtain a composite adsorbent 3 with a porosity of 0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com